Introduction

Definition of carbide cutting rods

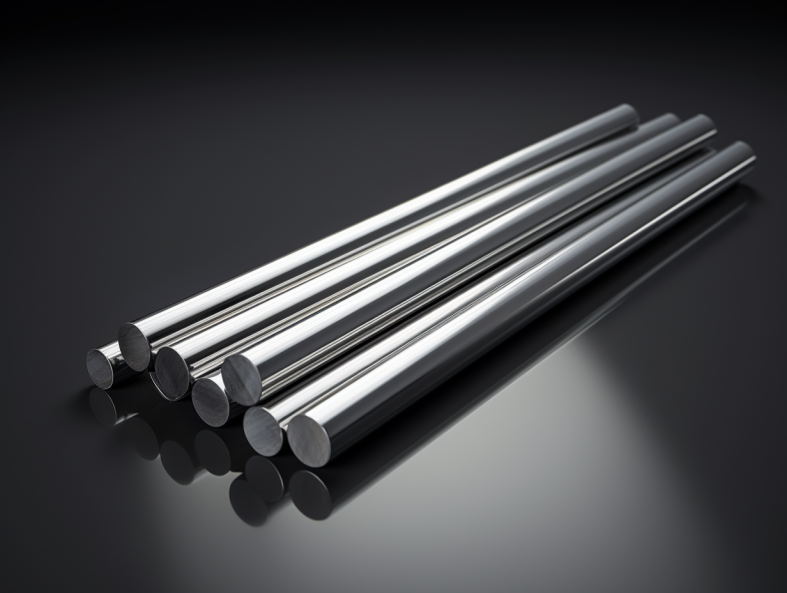

Carbide cutting rods are specialized tools used in various industries for cutting and shaping hard materials. They are made from a combination of tungsten carbide and cobalt, which gives them exceptional hardness and durability. These cutting rods are commonly used in manufacturing, construction, and metalworking applications to cut through materials such as steel, stainless steel, cast iron, and aluminum. The sharp cutting edges of carbide cutting rods allow for precise and efficient cutting, making them a preferred choice for many professionals. With their high resistance to wear and heat, carbide cutting rods are able to withstand the demanding conditions of heavy-duty cutting tasks. Overall, carbide cutting rods are essential tools that play a crucial role in achieving accurate and efficient cutting in various industries.

Applications of carbide cutting rods

Carbide cutting rods find a wide range of applications in various industries. One of the key applications of carbide cutting rods is in the metalworking industry, where they are used for cutting and shaping metal components with precision and efficiency. These cutting rods are also commonly used in the woodworking industry for cutting and shaping wood materials. Additionally, carbide cutting rods are utilized in the construction industry for cutting through tough materials such as concrete and stone. Their durability and hardness make them ideal for heavy-duty cutting tasks. Overall, the applications of carbide cutting rods extend to multiple industries, making them an essential tool for professionals in various fields.

Importance of carbide cutting rods

Carbide cutting rods play a crucial role in various industries due to their immense importance. These cutting tools are known for their exceptional strength, durability, and precision, making them an essential component in cutting and shaping various materials. Whether it is metal, wood, or plastic, carbide cutting rods provide superior performance and efficiency, ensuring clean and precise cuts. Moreover, their resistance to wear and tear allows for extended use, reducing the need for frequent replacements. With their ability to withstand high temperatures and maintain sharpness, carbide cutting rods are a reliable choice for professionals and DIY enthusiasts alike. Overall, the importance of carbide cutting rods cannot be overstated as they significantly enhance productivity and accuracy in cutting applications.

Composition of Carbide Cutting Rods

Materials used in carbide cutting rods

Carbide cutting rods are made using a variety of materials to ensure their durability and effectiveness. One commonly used material is tungsten carbide, which is known for its exceptional hardness and resistance to wear. This makes it ideal for cutting through tough materials such as steel and concrete. Another material often used in carbide cutting rods is cobalt, which helps enhance the strength and toughness of the rods. Additionally, carbide cutting rods may also incorporate other elements such as titanium or nickel to further improve their performance and longevity. With these carefully selected materials, carbide cutting rods are able to provide precise and efficient cutting, making them indispensable tools in various industries.

Manufacturing process of carbide cutting rods

Carbide cutting rods are manufactured using a precise and intricate process. The first step involves selecting high-quality tungsten carbide, which is known for its exceptional hardness and durability. The selected carbide is then mixed with a binder material, such as cobalt, to form a solid and uniform mixture. This mixture is then pressed and compacted into the desired shape and size using specialized machinery. After the compaction process, the rods are sintered at high temperatures to bond the carbide particles together, resulting in a strong and rigid structure. The sintered rods are then subjected to additional machining and grinding processes to achieve the final dimensions and surface finish. Finally, the rods undergo rigorous quality control inspections to ensure they meet the required specifications. The manufacturing process of carbide cutting rods combines advanced technology, precision engineering, and strict quality standards to produce tools that are highly effective in cutting various materials with precision and efficiency.

Properties of carbide cutting rods

Carbide cutting rods are known for their exceptional properties that make them a preferred tool in various industries. One of the key properties of carbide cutting rods is their high hardness, which allows them to withstand the extreme forces and temperatures encountered during cutting operations. This hardness also ensures a longer tool life, reducing the need for frequent replacements. Additionally, carbide cutting rods have excellent wear resistance, enabling them to maintain their cutting edge for extended periods. Furthermore, these cutting rods exhibit high heat resistance, preventing deformation and ensuring consistent performance even in demanding applications. With their superior properties, carbide cutting rods are indispensable in achieving precision and efficiency in cutting operations.

Types of Carbide Cutting Rods

Solid carbide cutting rods

Solid carbide cutting rods are high-performance tools used in various machining operations. These rods are made from a solid piece of carbide, which provides exceptional hardness and durability. The unique composition of carbide allows for precise cutting and shaping of materials, making it an ideal choice for industries such as automotive, aerospace, and manufacturing. With their superior strength and resistance to wear, solid carbide cutting rods offer extended tool life and improved productivity. Whether it’s milling, turning, or drilling, these cutting rods deliver consistent and reliable performance, ensuring high-quality results. Invest in solid carbide cutting rods and experience the difference in your machining operations.

Brazed carbide cutting rods

Brazed carbide cutting rods are an essential tool in the field of metalworking. These rods are made by brazing a carbide insert onto a steel shank, creating a strong and durable cutting edge. With their sharpness and hardness, brazed carbide cutting rods are capable of efficiently cutting through various materials, including steel, cast iron, and aluminum. The precision and accuracy provided by these cutting rods make them a popular choice among professionals in industries such as automotive, aerospace, and manufacturing. Whether it’s for shaping, grooving, or facing, brazed carbide cutting rods offer exceptional performance and reliability, making them an indispensable tool for any metalworking task.

Indexable carbide cutting rods

Indexable carbide cutting rods are a type of cutting tool used in various machining operations. These rods are made from carbide, a hard and durable material that allows for efficient cutting and extended tool life. The indexable design of these cutting rods allows for easy replacement of worn or damaged cutting edges, reducing downtime and increasing productivity. With their ability to provide precision cutting and excellent performance, indexable carbide cutting rods are widely used in industries such as automotive, aerospace, and manufacturing. Whether it’s for milling, turning, or drilling applications, these cutting rods are a reliable choice for achieving high-quality and efficient machining results.

Advantages of Carbide Cutting Rods

High hardness and wear resistance

Carbide cutting rods are known for their exceptional high hardness and wear resistance. These cutting tools are specifically designed to withstand the demanding conditions of cutting and machining operations. With their superior hardness, carbide cutting rods can effectively cut through tough materials such as steel, cast iron, and stainless steel. Moreover, their excellent wear resistance ensures a longer tool life, reducing the need for frequent tool replacements. This makes carbide cutting rods a popular choice among professionals in various industries, including automotive, aerospace, and manufacturing. Whether it’s for precision cutting or heavy-duty machining, carbide cutting rods offer unmatched performance and durability.

Excellent cutting performance

Carbide cutting rods are known for their excellent cutting performance. With their superior hardness and strength, these rods can effortlessly slice through even the toughest materials. Whether you’re working with metal, wood, or plastic, carbide cutting rods provide precise and clean cuts, making them the go-to choice for professionals and DIY enthusiasts alike. Additionally, their durability ensures long-lasting performance, reducing the need for frequent replacements. If you’re looking for a cutting tool that delivers exceptional results, look no further than carbide cutting rods.

Long tool life

Carbide cutting rods are known for their exceptional long tool life. The high hardness and wear resistance of carbide make it ideal for cutting applications that require extended usage. With a longer tool life, users can perform more cuts without the need for frequent tool replacements, resulting in increased productivity and cost savings. Additionally, the longevity of carbide cutting rods ensures consistent and precise cutting performance, providing reliable and high-quality results. Whether it’s for industrial or DIY projects, carbide cutting rods with their long tool life are a reliable choice for efficient and effective cutting operations.

Applications of Carbide Cutting Rods

Metalworking industry

The metalworking industry plays a crucial role in various sectors, including manufacturing, construction, and automotive. One essential tool used in metalworking is carbide cutting rods. These rods are known for their durability and precision, making them ideal for cutting through tough materials like steel and aluminum. With their sharp edges and resistance to wear, carbide cutting rods enable metalworkers to achieve precise and smooth cuts, resulting in high-quality finished products. Whether it’s shaping metal components or creating intricate designs, carbide cutting rods are a valuable asset in the metalworking industry.

Woodworking industry

The woodworking industry plays a crucial role in various sectors, including construction, furniture manufacturing, and interior design. One essential tool used in this industry is carbide cutting rods. These rods are known for their durability and precision, making them ideal for cutting through different types of wood. Whether it’s crafting intricate designs or shaping large wooden pieces, carbide cutting rods provide the necessary strength and accuracy to achieve high-quality results. Woodworkers rely on these rods to enhance their productivity and create intricate woodwork that meets the demands of the modern woodworking industry.

Automotive industry

The automotive industry is a key sector in the global economy, comprising of companies involved in the design, development, manufacturing, marketing, and selling of motor vehicles. Carbide cutting rods play a crucial role in the automotive industry, as they are used for various cutting and machining applications. These rods are made from a durable and wear-resistant material, known as carbide, which allows them to withstand the high demands and pressures of automotive manufacturing. With their excellent cutting performance and long lifespan, carbide cutting rods ensure precision and efficiency in the production of automotive components, contributing to the overall quality and reliability of vehicles.

Maintenance and Care of Carbide Cutting Rods

Proper cleaning and storage

Proper cleaning and storage of carbide cutting rods is essential to maintain their performance and prolong their lifespan. After each use, it is important to remove any excess debris and coolant from the rods to prevent buildup and corrosion. This can be done using a soft brush or cloth. Additionally, it is recommended to store the cutting rods in a cool and dry place to avoid moisture and humidity, which can also lead to corrosion. By following these simple cleaning and storage practices, you can ensure that your carbide cutting rods remain in optimal condition and provide efficient and precise cutting results for a long time.

Regular sharpening and reconditioning

Regular sharpening and reconditioning of carbide cutting rods is essential to maintain their effectiveness and prolong their lifespan. Over time, these cutting rods can become dull and lose their sharpness, resulting in reduced cutting performance. By regularly sharpening and reconditioning the rods, you can ensure that they remain sharp and efficient, allowing for clean and precise cuts. Additionally, reconditioning the rods helps to remove any built-up debris or residue, further enhancing their cutting ability. It is recommended to follow the manufacturer’s guidelines for sharpening and reconditioning frequency to maximize the longevity and performance of carbide cutting rods.

Avoiding excessive heat and impact

When using carbide cutting rods, it is important to take precautions to avoid excessive heat and impact. Excessive heat can cause the carbide to lose its hardness and effectiveness, leading to reduced cutting performance. To prevent this, it is recommended to use coolant or lubricants during the cutting process. Additionally, it is crucial to avoid subjecting the carbide cutting rods to excessive impact or force, as this can cause them to chip or break. By following these guidelines, users can ensure the longevity and optimal performance of their carbide cutting rods.