Unleashing Efficiency at the Coalface: 2 Key Carbide Button Designs for Superior Performance

The relentless demand for coal as a vital energy source necessitates robust and efficient mining operations. At the heart of this demanding industry lie coal mining carbide buttons, engineered to withstand the punishing conditions of underground and surface coal extraction. This guide focuses on two key button designs—conical and mushroom-shaped—unveiling their unique advantages and how they contribute to maximizing productivity and minimizing downtime in coal mining applications.

Why Carbide Buttons Are Indispensable in Coal Mining

Beyond Ordinary Wear Parts: Understanding the Value Proposition

- Unmatched Hardness: Tungsten carbide, the core material of these buttons, possesses exceptional hardness, surpassing most metals and significantly exceeding the hardness of coal and surrounding rock formations.

- Superior Wear Resistance: This inherent hardness translates to outstanding wear resistance, enabling carbide buttons to withstand the abrasive forces encountered during coal extraction, extending tool life, and reducing maintenance costs.

- Impact Resistance: Coal mining operations involve significant impact and shock loads. Carbide buttons are engineered to absorb these forces, preventing premature failure and ensuring consistent performance.

Conical vs. Mushroom-Shaped: Decoding the Design Differences

Shape Dictates Function: How Geometry Influences Performance

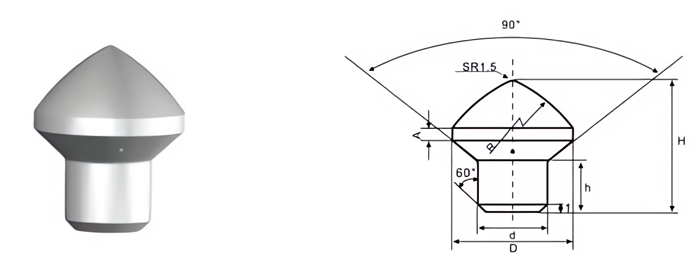

1. Conical Buttons:

- Characteristics: These buttons feature a tapered, conical shape with a pointed tip, designed for aggressive penetration.

- Advantages: Excel in cutting and breaking through hard coal seams and rock strata, offering high drilling rates and efficient material removal.

- Ideal For: Rotary drilling applications, cutting picks for continuous miners, and other tools requiring a focused cutting action.

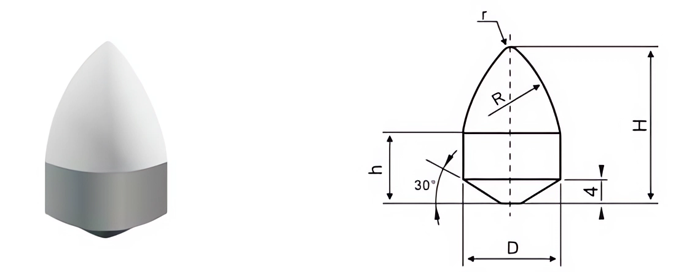

2. Mushroom-Shaped Buttons:

- Characteristics: These buttons have a distinctive domed or mushroom-like shape with a wider, flattened top surface.

- Advantages: Provide a balance of penetration and wear resistance, making them suitable for applications involving both cutting and crushing actions. The wider surface area also aids in distributing wear more evenly.

- Ideal For: Road headers, shearers, and other coal extraction equipment where a combination of cutting, scraping, and crushing is required.

Technical Specifications: A Comparative Look at Button Properties

From Composition to Standards: Key Data Points

| Feature | Conical Buttons | Mushroom-Shaped Buttons |

|---|---|---|

| Type | Conical | Mushroom-Shaped |

| Composition | Tungsten Carbide (WC) with Cobalt (Co) or Nickel (Ni) binder | Tungsten Carbide (WC) with Cobalt (Co) or Nickel (Ni) binder |

| Hardness (HV30) | 1500 – 1900 | 1450 – 1850 |

| Transverse Rupture Strength (N/mm²) | 1900 – 2600 | 1850 – 2550 |

| Impact Resistance | Very Good | Good |

| Wear Resistance | Very good in penetration and cutting applications | Good balance of wear and penetration resistance |

| Sizes and Shapes | Various diameters and tip angles available | Various diameters and dome heights available |

| Grades and Standards | Meet ISO, ASTM, and other relevant industry standards | Meet ISO, ASTM, and other relevant industry standards |

Applications in Coal Mining: Where Each Button Type Excels

From Extraction to Material Handling: A Range of Use Cases

- Underground Coal Mining:

- Continuous Miners: Conical buttons are commonly used on the rotating drums of continuous miners for their aggressive cutting ability in coal seams.

- Road Headers: Mushroom-shaped buttons are often preferred on road headers, which cut and load coal simultaneously, due to their balance of wear and penetration resistance.

- Longwall Mining: Both conical and mushroom-shaped buttons find applications in longwall shearers, with the choice depending on the specific geological conditions and cutting requirements.

- Surface Coal Mining:

- Drilling and Blasting: Conical buttons are used in drill bits for blast hole drilling in surface mines due to their efficient penetration capabilities.

- Dragline Buckets: Mushroom-shaped buttons are often incorporated into the teeth and cutting edges of dragline buckets for their ability to withstand the abrasive forces of scooping and loading coal.

Comparative Analysis: TRUER vs. Industry Leaders

Navigating the Market: A Side-by-Side Comparison

| Supplier | Location | Country | Price Range (per piece) | Specialties |

|---|---|---|---|---|

| TRUER | Shanghai, China | China | $10 – $50+ | Custom-engineered solutions, rapid prototyping, exceptional customer support |

| Element Six | Global Headquarters: London, UK | UK | $16 – $65+ | Advanced material science, high-performance carbide grades for extreme wear applications |

| Kennametal | Global Headquarters: Pittsburgh, PA | USA | $13 – $55+ | Wide range of standard and custom button designs, extensive industry experience |

| Sandvik Coromant | Global Headquarters: Sandviken, Sweden | Sweden | $15 – $70+ | Innovative tooling solutions, focus on sustainability and performance optimization |

Note: Prices are approximate and can vary significantly based on button size, geometry, grade, quantity, and other factors.If you want to purchase affordable, corrosion-resistant and durable carbide buttons, click here.

Advantages and Limitations: Weighing the Trade-offs

Making Informed Decisions: A Balanced View of Each Button Type

| Button Type | Advantages | Limitations |

|---|---|---|

| Conical | – High penetration rate, ideal for hard coal and rock<br> – Efficient material removal, leading to faster drilling and cutting | – Can be prone to breakage under extreme side loads<br> – Higher wear rates compared to mushroom-shaped buttons in applications involving significant scraping and crushing |

| Mushroom-Shaped | – Good balance of penetration and wear resistance<br> – Wider surface area distributes wear more evenly<br> – Suitable for a combination of cutting, scraping, and crushing actions | – Lower penetration rate compared to conical buttons<br> – Not ideal for applications requiring aggressive cutting in very hard formations |

Beyond the Basics: Factors Influencing Button Performance and Longevity

Maximizing ROI: Key Considerations

- Carbide Grade Selection: Choosing the appropriate grade of tungsten carbide is crucial, considering factors like the hardness of the coal and rock, impact resistance requirements, and the presence of abrasive minerals.

- Button Attachment Method: Proper brazing or welding techniques are essential for ensuring a secure bond between the button and the mining tool, preventing premature button loss.

- Operating Parameters: Factors like cutting speed, depth of cut, and the use of cutting fluids can significantly influence button wear rates and overall performance.

Why Choose TRUER?

Your Partner in Coal Mining Efficiency:

TRUER is committed to providing more than just carbide buttons; we offer solutions tailored to optimize your coal mining operations. Here’s why industry leaders choose TRUER:

- Unwavering Quality: We source only the highest-grade tungsten carbide and adhere to rigorous quality control measures throughout our manufacturing process.

- Customization Expertise: Our team of engineers excels at designing and manufacturing custom button solutions to meet your specific coal mining challenges.

- Rapid Prototyping and Production: We understand the importance of minimizing downtime in the mining industry. Our streamlined processes enable us to deliver prototypes and production runs efficiently.

- Exceptional Customer Support: We’re with you every step of the way, providing expert technical guidance and support to ensure your success.

Frequently Asked Questions: Addressing Your Coal Mining Button Queries

1. How do I choose the right carbide button type and grade for my specific coal mining application?

The optimal button type and grade depend on factors like the hardness of the coal seam, the type of mining equipment used, and the desired balance between penetration and wear resistance. Consulting with our technical experts is recommended for personalized guidance.

2. What are the typical wear patterns observed in conical and mushroom-shaped buttons, and how can I identify when replacement is needed?

Wear patterns vary depending on the button type and operating conditions. Common signs of wear include tip blunting or chipping in conical buttons and flattening or grooving of the top surface in mushroom-shaped buttons. Regular inspection and replacement based on established wear limits are crucial.

3. Can TRUER provide carbide buttons with specialized coatings for enhanced wear or corrosion resistance in demanding coal mining environments?

Yes, we offer a range of surface treatments and coatings that can further enhance the performance and longevity of our buttons in the presence of abrasive minerals, corrosive agents, and other challenging conditions.

4. What is the typical lead time for ordering custom carbide buttons from TRUER?

Lead times for custom orders vary depending on the complexity of the design and the quantity required. Contact our sales team for a personalized quote and lead time estimate.

5. Does TRUER offer on-site technical support or training related to the use and maintenance of your carbide buttons in coal mining applications?

We provide comprehensive technical support, including on-site consultations, training programs, and troubleshooting assistance, to ensure you get the most out of our products and optimize your coal mining operations.