Beyond Hardness: Unlocking the Secrets of Optimized Carbide Button Design

In the demanding world of wear-resistant components, carbide buttons are renowned for their exceptional durability. But did you know that the geometry and design of these small but mighty components play a crucial role in maximizing their performance and lifespan?

This comprehensive guide delves into the fascinating interplay between carbide button shape, application requirements, and wear resistance, empowering you to make informed decisions that optimize performance and extend equipment life.

Why Geometry Matters: Understanding the Impact

More Than Meets the Eye: How Shape Influences Wear Behavior

While the carbide grade itself dictates fundamental properties like hardness and toughness, the button’s geometry significantly influences how these properties translate to real-world performance. Here’s why:

- Stress Distribution: The shape of a carbide button affects how stress from impact, abrasion, and other wear mechanisms is distributed across its surface. Optimizing this distribution can minimize stress concentrations and reduce the risk of chipping, cracking, or premature wear.

- Material Flow: In applications involving abrasive materials, the button’s geometry can influence how these materials flow around and interact with its surface. Strategic shaping can promote material deflection, reducing direct abrasion and extending button life.

- Self-Sharpening: Some button designs incorporate features that promote self-sharpening as the button wears down. This helps maintain cutting or grinding efficiency over a longer period, reducing downtime for replacement.

- Attachment Strength: The button’s geometry also influences the strength and reliability of its attachment to the base material. Proper design ensures a secure bond, preventing button loss and maximizing wear life.

Key Geometric Features and Their Effects

A Closer Look at the Building Blocks of Button Design

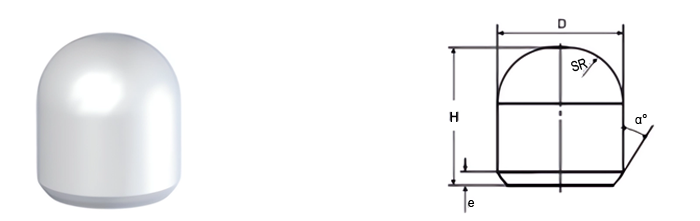

- Face Shape: The shape of the button’s exposed face, which comes into contact with the wear surface, is critical. Common shapes include:

- Round: Versatile, offering good all-around wear resistance.

- Hexagonal: Provides increased surface area for better wear distribution and can enhance self-sharpening.

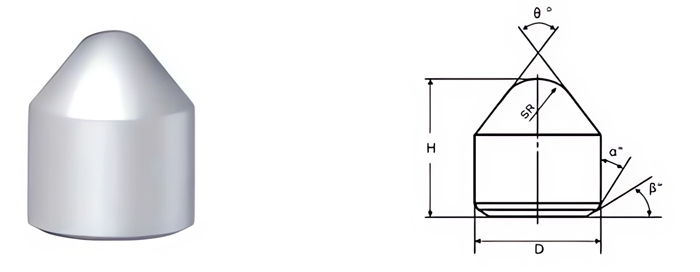

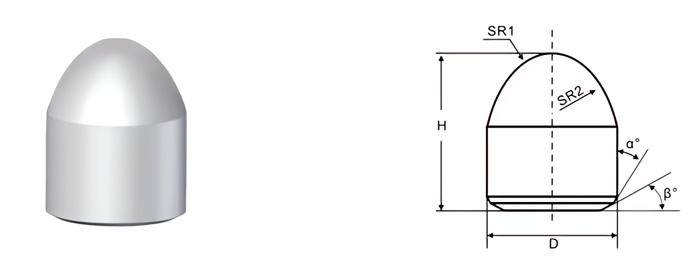

- Ballistic: Designed for extreme impact resistance, often used in applications like rock crushing.

- Conical: Promotes material flow and reduces clogging in applications like drilling or earthmoving.

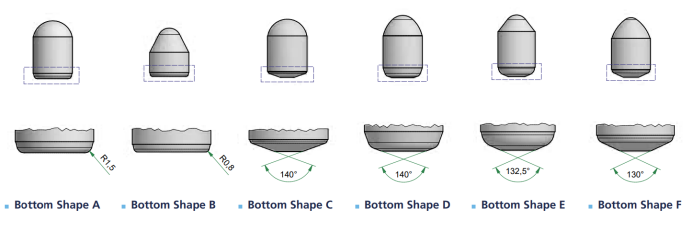

- Face Profile: The contour of the button’s face can be flat, concave, or convex, each influencing wear behavior:

- Flat: Provides even wear distribution but can be more susceptible to chipping under high impact.

- Concave: Enhances self-sharpening and can improve material penetration in cutting or drilling applications.

- Convex: Offers increased resistance to impact and abrasion but may sacrifice some cutting efficiency.

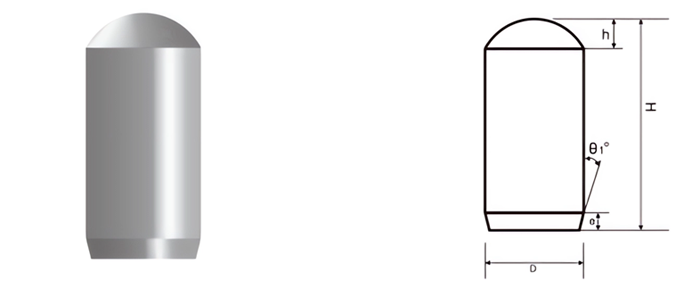

- Shank Design: The shank is the portion of the button that’s embedded in the base material and provides anchorage:

- Straight Shank: Simple and cost-effective, suitable for applications with moderate wear and impact.

- Counterbored Shank: Provides increased surface area for stronger attachment, enhancing resistance to pull-out forces.

- Dovetail Shank: Offers exceptional resistance to pull-out, ideal for high-impact applications.

- Button Size: Larger buttons generally offer greater wear volume and can withstand higher impact forces, but may compromise penetration or require more robust attachment methods. Smaller buttons provide better contouring on complex surfaces and can be more cost-effective for applications with lower wear rates.

- Spacing and Arrangement: The spacing and arrangement of carbide buttons on a wear surface also influence performance. Factors to consider include:

- Wear Pattern: Analyzing existing wear patterns can help optimize button placement for maximum protection.

- Material Flow: Spacing buttons strategically can promote efficient material flow and minimize clogging.

- Impact Distribution: Distributing impact forces evenly across multiple buttons can reduce the risk of individual button failure.

Matching Geometry to Application: Finding the Perfect Fit

A Guide to Optimizing Performance for Specific Industries

| Application | Key Challenges | Recommended Geometry Features |

|---|---|---|

| Mining (Drilling) | Abrasion, impact, rock fragmentation | Conical or ballistic face shape, counterbored or dovetail shank for secure attachment |

| Construction (Road Milling) | High abrasion, impact from aggregates | Hexagonal or round face shape, flat or concave face profile for self-sharpening |

| Agriculture (Tillage) | Abrasion from soil and rocks, impact resistance | Round or conical face shape, moderate shank depth for secure attachment in varying soil conditions |

| Recycling (Shredding) | Impact resistance, wear from various materials | Ballistic or heavily reinforced round face shape, robust shank design for secure attachment |

Beyond the Basics: Advanced Design Considerations

- Finite Element Analysis (FEA): Sophisticated computer simulations can be used to model stress distribution and wear patterns under various operating conditions, allowing for highly optimized button designs.

- Custom Designs: For specialized applications with unique wear challenges, custom button designs can be created to precisely match performance requirements.

- Wear Monitoring and Analysis: Regularly monitoring wear patterns on carbide buttons can provide valuable insights for further optimizing geometry and extending lifespan.

Frequently Asked Questions:

1. What are the main advantages of using hexagonal carbide buttons?

Hexagonal buttons offer increased surface area compared to round buttons, which can enhance wear distribution and promote self-sharpening.

2. How does button size affect performance in high-impact applications?

Larger buttons generally offer greater wear volume and can withstand higher impact forces. However, they may require more robust attachment methods to prevent dislodging.

3. Why is proper spacing important when arranging carbide buttons on a wear surface?

Proper spacing ensures even wear distribution, promotes efficient material flow, and helps prevent clogging, especially in applications involving abrasive materials.

4. Can I use the same carbide button geometry for both drilling and crushing applications?

While some button shapes offer versatility, it’s generally recommended to choose geometries specifically designed for the intended application. Drilling and crushing, for example, involve different wear mechanisms and force directions.

5. How can I determine the optimal carbide button geometry for my specific application?

Consulting with a carbide button supplier or materials engineer experienced in wear applications is highly recommended. They can assess your specific needs, considering factors like wear mechanisms, materials being processed, and operating conditions, to recommend the most suitable button geometry and grade.

Conclusion: Unlocking the Full Potential of Carbide Buttons

Understanding the profound impact of geometry and design on carbide button performance is crucial for maximizing wear life, reducing downtime, and optimizing overall efficiency. By carefully considering the specific challenges of your application and working with a knowledgeable supplier, you can unlock the full potential of these durable components and extend the lifespan of your valuable equipment.