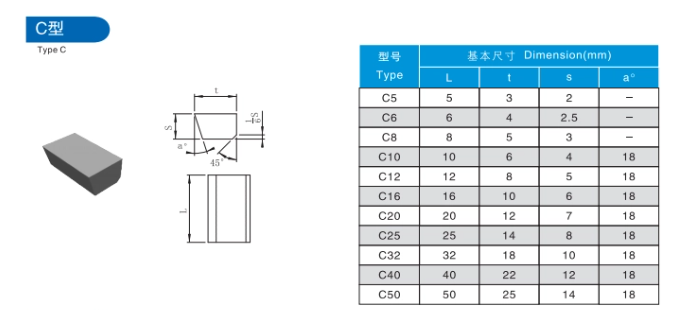

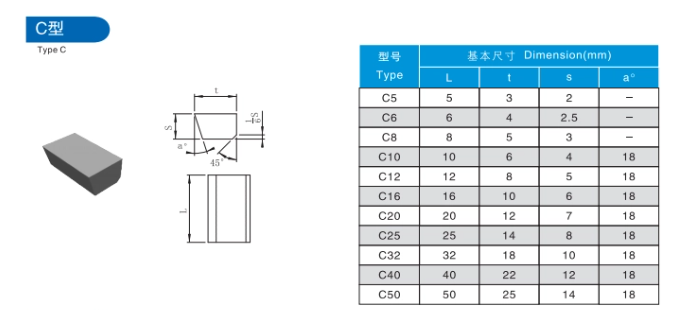

Type C Carbide Brazed Tips for Impeccable Surface Finishes

At the forefront of this pursuit stand Type C carbide brazed tips, meticulously engineered to deliver the ultimate in surface quality and dimensional accuracy.

At the forefront of this pursuit stand Type C carbide brazed tips, meticulously engineered to deliver the ultimate in surface quality and dimensional accuracy.

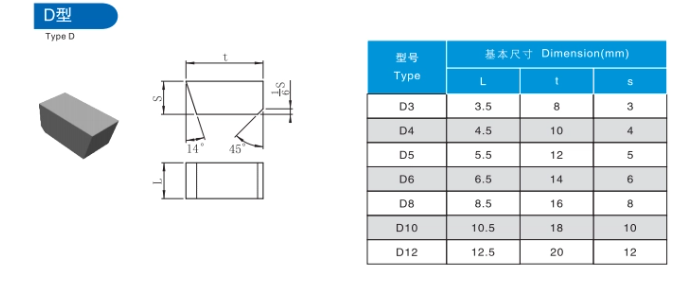

Enter Type D carbide brazed tips, the workhorses of the machining world, engineered to conquer the most challenging cutting conditions with unmatched power and resilience.

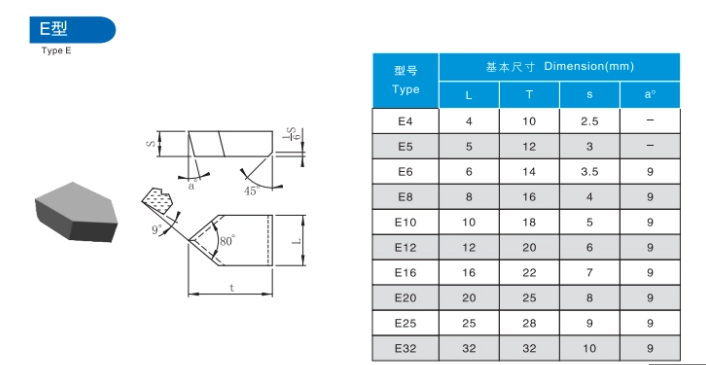

This is the realm of copy milling, a machining process that relies on the precision and accuracy of Type E carbide brazed tips to create exact copies of master patterns or models.

Enter Type F carbide brazed tips, the unsung heroes of the machining world, meticulously engineered to deliver exceptional accuracy and surface finish in demanding finishing and semi-finishing operations.

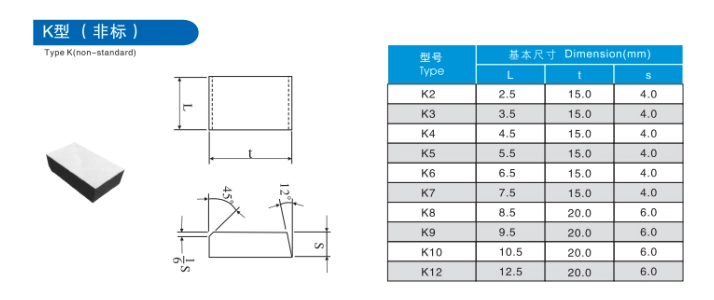

Enter Type K carbide brazed tips, the heavy-duty champions engineered to withstand the most punishing cutting conditions while delivering exceptional performance and tool life.

Overview of Tungsten Carbide Indexable Inserts Tungsten carbide indexable inserts are a cornerstone in the world of machining. Whether you’re cutting, turning, milling, or boring, these tiny powerhouses are essential. They provide the durability and precision needed to tackle even

Enter corrosion-resistant carbide tube blanks – the unsung heroes engineered to withstand the toughest challenges and deliver uncompromising performance.

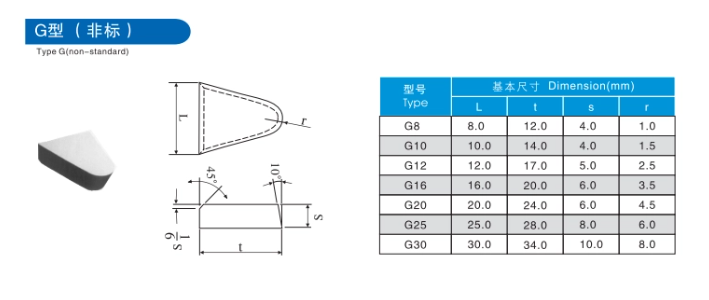

Enter Type G carbide brazed tips, the specialized tools engineered to conquer the intricacies of cast iron machining, delivering exceptional performance, tool life, and surface finish.

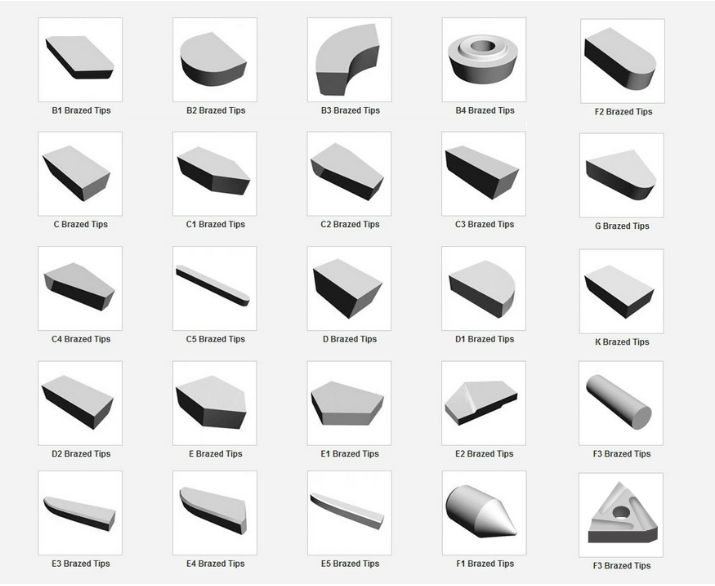

Carbide brazed tips are a key component in the machining industry, offering unparalleled hardness, durability, and cutting efficiency.

high-quality tungsten carbide buttons emerge as unsung heroes, quietly powering industries ranging from mining and construction to oil and gas exploration.