Tungsten Carbide End Mills: Unlocking 10x the Performance in Precision Machining

Tungsten carbide end mills stand as the pinnacle of cutting tool technology, enabling manufacturers across industries to achieve unprecedented levels of precision,

Tungsten carbide end mills stand as the pinnacle of cutting tool technology, enabling manufacturers across industries to achieve unprecedented levels of precision,

Cemented carbide end mills stand as the cornerstone of modern machining, offering unparalleled precision, durability, and versatility in shaping a vast array of materials.

Solid carbide end mills are essential tools in the machining industry, known for their precision, durability, and efficiency.

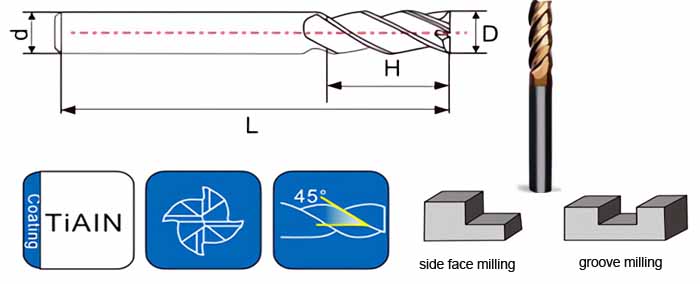

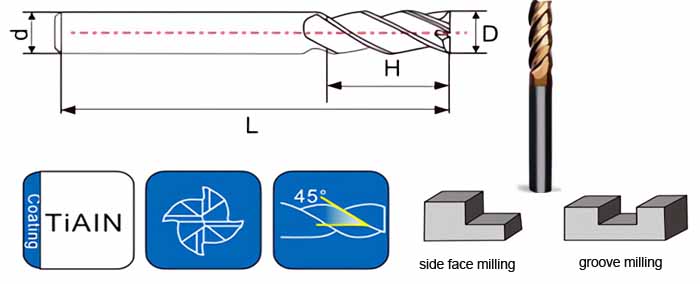

Carbide square end mills are indispensable tools in the world of machining, renowned for their ability to create precise 90-degree shoulders, slots, and profiles in a wide array of materials.

Two flute end mills are essential tools in the world of machining, prized for their ability to rapidly remove material and produce a smooth surface finish.

3 flute end mills are essential tools in the world of machining, prized for their ability to efficiently remove material and create a variety of features in workpieces.

4 flute end mills are indispensable tools in the world of machining, renowned for their ability to deliver a balance of aggressive material removal and smooth surface finishes.

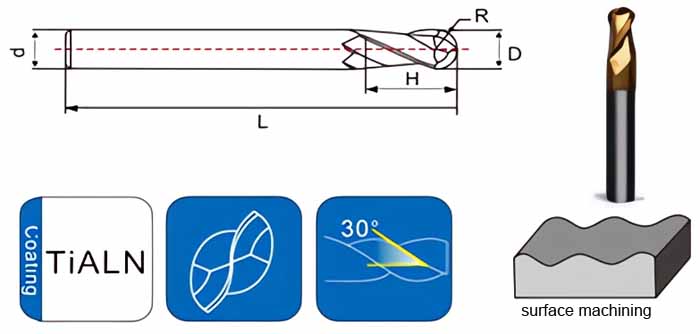

The geometry and design of a carbide end mill play a crucial role in its cutting performance. Understanding these factors can significantly enhance machining efficiency, tool longevity, and surface finish quality.

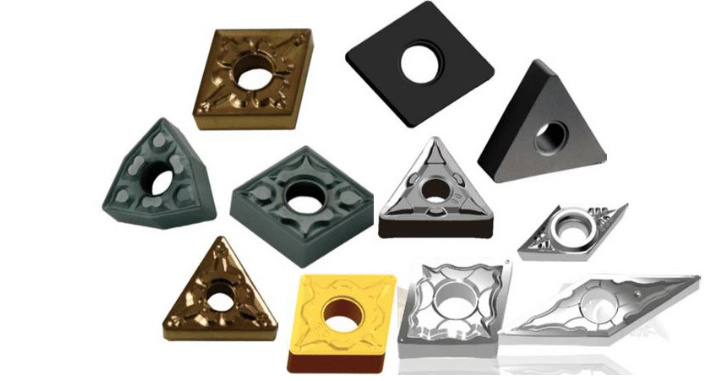

In the relentless pursuit of efficiency and precision, the world of machining has witnessed a revolution driven by carbide inserts.

In the world of machining, general turning inserts are the workhorses that shape and refine cylindrical workpieces, driving efficiency and precision across industries.