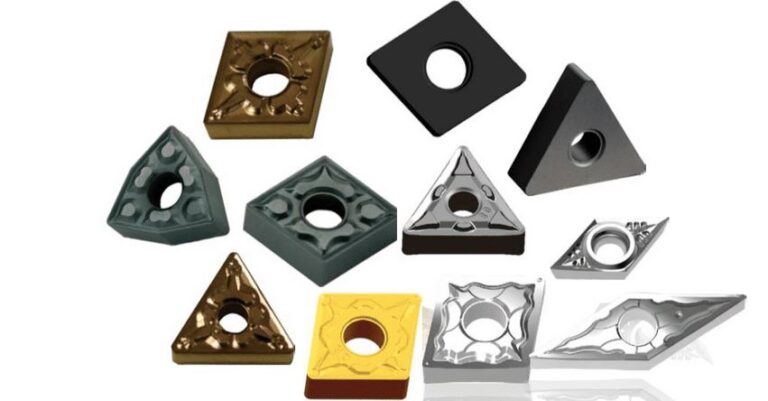

Carbide Blanks: Types, Applications and Selection

Overview of Carbide Blanks Carbide blanks, also known as tungsten carbide blanks, are foundational materials used in various manufacturing processes. These materials are crafted from carbide powders and are known for their extreme hardness, wear resistance, and ability to maintain…