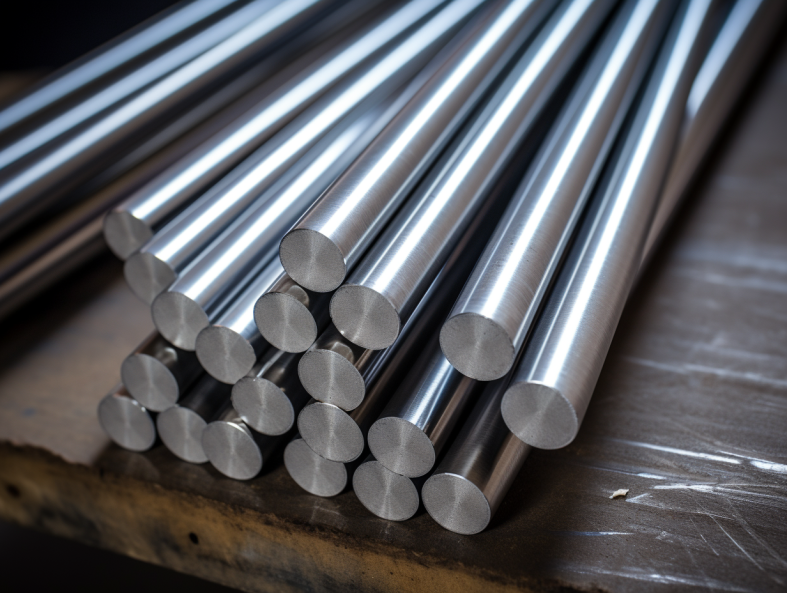

- Carbide Rods

Grade properties

| Grade | ISO Code | Grain Size {um} | Cobalt Content {wt%} | Density {g/cm³} | Hardness{HAR} | TRS{N/mm²} |

|---|---|---|---|---|---|---|

| TS710 | K20-K30 | 0.7 | 10.0 | 14.45 | 91.8 | 3800 |

| TS610 | K20-K30 | 0.6 | 10.0 | 14.45 | 92.2 | 4000 |

| TU412 | K30-K40 | 0.4 | 12.0 | 14.12 | 92.5 | 4200 |

| TU409 | K10-K20 | 0.4 | 9.0 | 14.50 | 93.2 | 4000 |

| TU406 | K05-K10 | 0.4 | 6.0 | 14.8 | 94.1 | 3800 |

| TN209 | K20-K30 | 0.2 | 9.0 | 14.45 | 94.0 | 4200 |

| TS715 | K30-K40 | 0.7 | 15.0 | 13.98 | 89.0 | 4500 |

| TU408 | K10-K20 | 0.4 | 8.5 | 14.52 | 93.5 | 3800 |

| TU510 | K20-K40 | 0.5 | 10.3 | 14.30 | 92.3 | 4200 |

| TU512A | K20-K40 | 0.5 | 12.0 | 14.10 | 92.0 | 4200 |

| TU512B | K20-K40 | 0.5 | 12.0 | 14.10 | 91.2 | 4500 |

| TS606 | K10 | 0.6 | 6.0 | 14.90 | 93.3 | 3800 |

| TS613 | K30-K40 | 0.6 | 13.5 | 14.08 | 90.5 | 4000 |

| TM1512 | K30-K40 | 1.0-2.0 | 12.5 | 14.10 | 89.5 | 3600 |

| TM2214 | K40-K50 | 1.5-3.0 | 14.0 | 14.00 | 88.5 | 3700 |

| TC2406 | 0.8-4.0 | 6.0 | 14.80 | 90.5 | 2900 | |

| TF1113A | 0.8-1.5 | 13.0 | 14.20 | 90.0 | 3000 | |

| TF1113B | 0.8-1.5 | 13.5 | 14.00 | 90.0 | 3600 | |

| TM1513 | 1.0-2.0 | 13.0 | 14.20 | 89.5 | 3800 | |

| TF1312 | 0.8-1.8 | 12.0 | 14.30 | 90.0 | 3500 | |

| TC2515 | 1.0-4.0 | 15.0 | 13.90 | 87.5 | 3500 |

Solid carbide rods are another type of carbide bar that is widely used in machining applications. These rods are made from a single piece of tungsten carbide material, making them highly durable and resistant to wear and tear . Solid carbide rods are suitable for machining a variety of materials such as steel, cast iron, and titanium alloys . They are also available in a range of diameters and lengths, making them suitable for use in various types of machinery.

Solid carbide rods are widely used for creating premium solid carbide tools, such as end mills, drills, reamers, milling cutters, stamping, and measuring tools in different industries. We supply both unground and ground solid carbide rods with top and consistent quality in varied grades. If you would like to learn more about our carbide grades, please find above the grade page.

A comprehensive standard selection of solid carbide rods in various dimensions is available clieck here, but other sizes, tolerances & configurations also available on request.

Cemented carbide rods, also known as tungsten carbide rods, have emerged as a cornerstone in modern industrial applications due to their unparalleled hardness, wear resistance, and durability. These rods have transformed machining, drilling, and other precision-requiring tasks. This comprehensive guide explores the world of cemented carbide rods, detailing their properties, working principles, usage, processing methods, classifications, and market trends. Whether you’re an industry veteran or a newcomer, this article provides valuable insights into the remarkable capabilities of cemented carbide rods.

Solid carbide rods, often referred to as tungsten carbide rods, are engineered materials renowned for their exceptional hardness, wear resistance, and ability to maintain their properties at high temperatures. Unlike tools with carbide inserts, these rods are crafted entirely from carbide material, ensuring consistent performance and extended tool life.

Carbide rods are widely used in various applications due to their exceptional hardness and wear resistance. Key uses include:

- Manufacturing Cutting Tools: Such as drills, endmills, and reamers.

- Precision Machining: For parts in the aerospace, automotive, and medical industries.

- Wear Parts: In machinery, including nozzles and punches.

- Mining and Construction Tools: Like drill bits and boring tools.

Their durability and performance make them ideal for demanding environments.

Carbide rods with the kind of internal cooling hole can provide much more efficient chip evacuation and deeper hole making capabilities, widely used in drills, reamers, carbide holders. We supply both unground and ground carbide rods with one cooling hole in varied grades. If you would like to learn more about our carbide grades, please find above the grade page.Read More

A comprehensive standard selection of carbide rods with one straight cooling hole in various dimensions is available click here, but other sizes, tolerances & configurations also available on request.

The 2-hole design on the carbide rod allows for increased coolant flow and better chip evacuation compared to a single-hole design. This helps to improve tool life and cutting performance, especially in high-speed machining operations where heat and chip buildup can be a problem, widely used in drills, reamers, carbide holders. We supply both unground and ground carbide rods with two cooling holes in varied grades. If you would like to learn more about our carbide grades, please find above the grade page.

A comprehensive standard selection of carbide rods with two straight cooling holes in various dimensions is available click here, but other sizes, tolerances & configurations also available on request.

Carbide rods with helical coolant holes greatly avoid the early wear and failure of the tungsten carbide tools during high-speed machining by the coolant in helical holes to reduce the temperature evenly, widely used in cutting and machining applications. The helix angle determines the efficiency of chip evacuation during the cutting process, which is critical for preventing tool wear and damage to the workpiece. We supply 30°& 40°helix,and unground & ground carbide rods with two helical cooling holes in varied grades. If you would like to learn more about our carbide grades, please find above the grade page.Read More

A comprehensive standard selection of carbide rods with helical cooling holes in various dimensions is available click here, but other sizes, tolerances & configurations also available on request.

One end of carbide rods is chamfered, which means that it is ground at an angle to create a beveled edge. This chamfered edge helps to reduce the amount of chipping and breakage that can occur during the drilling or milling process. It also improves the accuracy and precision of the cutting operation by creating a clean and smooth entry point for the tool.The carbide rod is ground to precise tolerances to ensure that it meets the exact specifications required for the specific application. This includes the diameter of the rod, the length of the rod, and the chamfer angle.Read More.

We supply chamfered carbide rods in varied tungsten carabide grades. If you would like to learn more about our carbide grades, please find above the grade page.

A comprehensive standard selection of carbide rods with chamfered end in various dimensions is available click here, but other sizes, tolerances & configurations also available on request.

But not all carbide rods are created equal. This comprehensive guide delves into the intricacies of four essential solid carbide rod types, each with unique features and advantages tailored to specific machining challenges:

- Straight Coolant Hole Carbide Rod

- 2 Straight Coolant Holes Carbide Rod

- 2 Helical Coolant Holes Carbide Rod

- End Chamfered Ground Carbide Rod