- Carbide saw tips

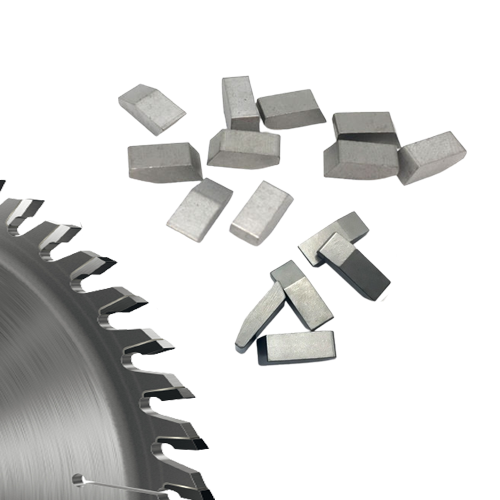

Carbide saw tips

Carbide saw tips allow multiple sharpening and long service life for saw mill cutting applications benefit from its excellent wear & corrosion resistant properties.

We supply carbide saw tips with different grades and sizes for a variety of applications, such wood, plastic, non-ferrous metals and stainless steels cutting. Our fine and submicron structure grades combined with the special metallurgical formulation of binder create a extremely wear resistant specially to cutting sandwich board and composite materials.

If you would like to learn more about our carbide grades for saw tips, please click on HERE to browse the grade page.

A comprehensive standard selection of saw tips in various dimensions is available in the below tables, but other sizes, tolerances & configurations also available on request.

Contact us if what you need is not shown here.

Introduction

Carbide saw tips are specialized cutting tools used in various industries, particularly in woodworking, metalworking, and construction. These tips are made from a compound known as carbide, which is a combination of tungsten and carbon. The resulting material is extremely hard and durable, making it ideal for applications that involve cutting through tough materials.

Composition and Structure

The composition of carbide saw tips can vary depending on the specific application and requirements. Different grades of carbide are available, with varying tungsten carbide content and binder proportions, allowing manufacturers to tailor the properties of the saw tips to suit different cutting needs.

The structure of carbide saw tips is typically a combination of tungsten carbide particles dispersed within a cobalt matrix. The tungsten carbide particles form the cutting edges of the saw tip, while the cobalt matrix provides support and strength. The distribution and arrangement of the tungsten carbide particles can vary, depending on the specific design and cutting requirements of the saw tip.

Hardness

Carbide saw tips are exceptionally hard, often ranking higher on the Mohs scale of hardness than other cutting materials like steel. Tungsten carbide, the main component of carbide tips, is one of the hardest materials known. This hardness allows the tips to maintain their cutting edges and resist wear, resulting in longer tool life and improved cutting performance.

Wear Resistance

Carbide saw tips exhibit excellent wear resistance, even when cutting through abrasive materials or performing high-speed cutting operations. The hardness and composition of carbide enable it to withstand the wear caused by the contact with the workpiece and the heat generated during cutting. This property extends the lifespan of the saw tips and reduces the frequency of tool replacements.

Strength and Toughness

Although carbide is extremely hard, it can be brittle. To enhance the overall strength and toughness of carbide saw tips, a metallic binder, typically cobalt, is used. The binder adds toughness and impact resistance, preventing the carbide from chipping or fracturing under heavy loads or sudden impacts. This combination of hardness and toughness allows carbide tips to endure demanding cutting conditions.

Heat Resistance

Carbide saw tips have excellent heat resistance, which is essential for cutting applications that generate high temperatures. The material can withstand the heat generated during cutting, preventing premature wear, and maintaining the sharpness of the cutting edge. The heat resistance of carbide also helps to reduce the risk of tool deformation or damage during prolonged use.

Chemical Stability

Carbide saw tips exhibit good chemical stability, making them resistant to corrosion or chemical reactions with various workpiece materials. This property allows carbide tips to be used for cutting applications involving different types of materials, including wood, metals, plastics, and composites.

Versatility

Carbide saw tips are highly versatile and can be used for cutting a wide range of materials, from softwoods to hardwoods, non-ferrous metals, and even some ferrous metals. Their ability to maintain sharpness and perform well across various materials makes them suitable for different industries and applications.

Powder Preparation

Tungsten carbide and cobalt powders are produced separately and carefully mixed.

Mixing

The tungsten carbide and cobalt powders are carefully mixed in predetermined proportions.

Pressing

Mixed powder is compacted under high pressure to form green compacts.

Pre-Sintering

Green compacts are partially densified through low-temperature sintering.

Shaping and Machining

Compacts are shaped and machined to achieve final dimensions and cutting edge geometry.

Final Sintering

Compacts undergo high-temperature sintering to form dense and solid structures.

Finishing and Coating

Additional processes such as grinding, polishing, and coating are applied for improved performance.

Quality Control

Stringent measures are implemented to ensure final carbide saw tips meet specifications.

Woodworking

Carbide saw tips are widely used in woodworking applications, including cutting, shaping, and profiling of different types of wood. They provide clean and precise cuts, allowing for efficient production of furniture, cabinetry, flooring, and other wooden products.

Metalworking

Carbide saw tips are also employed in metalworking applications, particularly in cutting non-ferrous metals like aluminum, brass, and copper. They offer superior cutting performance, high precision, and extended tool life, making them ideal for industries such as automotive, aerospace, and metal fabrication.

Construction

In the construction industry, carbide saw tips are utilized for cutting through various construction materials, including concrete, bricks, and masonry. They enable efficient and accurate cutting of these tough materials, making them essential for tasks like concrete formwork, tile installation, and general construction.

Composite Materials

Carbide saw tips are well-suited for cutting composite materials, such as fiberglass, carbon fiber, and laminates. These materials are commonly used in industries like aerospace, marine, and automotive. Carbide saw tips provide clean, chip-free cuts and ensure precise shaping and trimming of composite components.

Woodworking

Carbide saw tips are widely used in woodworking applications, including cutting, shaping, and profiling of different types of wood. They provide clean and precise cuts, allowing for efficient production of furniture, cabinetry, flooring, and other wooden products.

Metalworking

Carbide saw tips are also employed in metalworking applications, particularly in cutting non-ferrous metals like aluminum, brass, and copper. They offer superior cutting performance, high precision, and extended tool life, making them ideal for industries such as automotive, aerospace, and metal fabrication.

Construction

In the construction industry, carbide saw tips are utilized for cutting through various construction materials, including concrete, bricks, and masonry. They enable efficient and accurate cutting of these tough materials, making them essential for tasks like concrete formwork, tile installation, and general construction.

Composite Materials

Carbide saw tips are well-suited for cutting composite materials, such as fiberglass, carbon fiber, and laminates. These materials are commonly used in industries like aerospace, marine, and automotive. Carbide saw tips provide clean, chip-free cuts and ensure precise shaping and trimming of composite components.

Carbide saw tips are cutting tool components made from a composite material consisting of tungsten carbide and cobalt. These tips are brazed onto saw blades to enhance their cutting performance. Tungsten carbide provides extreme hardness and wear resistance, while cobalt acts as a binder to add toughness and durability.

- Wood Cutting: Essential in circular saw blades for precise and efficient wood cutting.

- Metal Cutting: Used in saws designed for cutting metals, providing clean and accurate cuts.

- Masonry Cutting: Integrated into tools for cutting bricks, tiles, and other masonry materials.

- Plastics Cutting: Utilized in tools for cutting various plastic materials with precision.

Tungsten carbide saw tips employ the principle of shear deformation to achieve clean, efficient cuts. The incredibly hard carbide tip, with its precisely ground cutting edge, acts as a wedge, concentrating force on the workpiece material. This concentrated force exceeds the material’s shear strength, causing it to separate along the desired cutting path.

Carbide saw tips can cut a wide range of materials, including hardwood, softwood, plastics, non-ferrous metals (such as aluminum and copper), and some ferrous metals. Their versatility makes them suitable for various industries and applications.

Carbide saw tip grades refer to the classification of carbide tips based on their composition, grain size, and performance characteristics. These grades dictate the tip’s hardness, toughness, wear resistance, and overall suitability for various cutting applications.

A wider, deeper gullet provides more space for chip removal, which is essential when cutting materials that produce large chips, such as softwoods or plastics.

TRUER provides detailed information on the tip geometry, including rake angle, clearance angle, and other features. This information can be found on the blade’s packaging or in the product detail page.

Solid carbide saw tips offer superior hardness, wear resistance, and precision compared to traditional steel tips. They maintain sharpness longer, provide cleaner cuts, and have a longer lifespan, reducing the need for frequent replacements.

Carbide saw tips are made from tungsten carbide, which is exceptionally hard and wear-resistant. This material maintains its sharpness and cutting edge far longer than other materials like high-speed steel or tool steel, resulting in greater durability and extended tool life.

Micrograin carbide features carbide particles less than 1 micron in size, offering high hardness and moderate toughness. Sub-micrograin carbide has even finer particles, typically less than 0.5 microns, providing superior hardness and wear resistance, ideal for high-speed and precision cutting.

Data

*The width (W) can be customized according to your needs

| Part No. | L/mm | T/mm | W/mm | T1/mm | α° | β° |

|---|---|---|---|---|---|---|

| ST-EU-4515 | 4.5 | 1.50 | w | 0.70 | 28.00 | 45.00 |

| ST-EU-5015 | 5.0 | 1.50 | w | 1.00 | 28.00 | 45.00 |

| ST-EU-5515 | 5.5 | 1.50 | w | 1.00 | 30.00 | 45.00 |

| ST-EU-6018 | 6.0 | 1.80 | w | 1.20 | 28.00 | 45.00 |

| ST-EU-6020 | 6.0 | 2.00 | w | 1.40 | 28.00 | 45.00 |

| ST-EU-6520 | 6.5 | 2.00 | w | 1.40 | 28.00 | 45.00 |

| ST-EU-7020 | 7.0 | 2.00 | w | 1.20 | 28.00 | 45.00 |

| ST-EU-7022 | 7.0 | 2.20 | w | 1.80 | 28.00 | 70.00 |

| ST-EU-7520 | 7.5 | 2.00 | w | 1.20 | 28.00 | 45.00 |

| ST-EU-8023 | 8.0 | 2.30 | w | 1.50 | 28.00 | 56.00 |

| ST-EU-8525 | 8.5 | 2.50 | w | 1.25 | 28.00 | 45.00 |

| ST-EU-8535 | 8.5 | 3.50 | w | 2.00 | 25.00 | 56.00 |

| ST-EU-9025 | 9.0 | 2.50 | w | 1.46 | 20.00 | 57.00 |

| ST-EU-10025 | 10.0 | 2.50 | w | 1.60 | 20.00 | 67.00 |

| ST-EU-10030 | 10.0 | 3.00 | w | 1.60 | 15.00 | 72.00 |

| ST-EU-10525 | 10.5 | 2.50 | w | 1.30 | 28.00 | 45.00 |

| ST-EU-10530 | 10.5 | 3.00 | w | 1.70 | 30.00 | 50.00 |

| ST-EU-10535 | 10.5 | 3.50 | w | 2.40 | 28.00 | 45.00 |

| ST-EU-12035 | 12.0 | 3.50 | w | 2.40 | 30.00 | 45.00 |

| ST-EU-12540 | 12.5 | 4.00 | w | 2.70 | 30.00 | 70.00 |

| ST-EU-13050 | 13.0 | 5.00 | w | 3.30 | 35.00 | 45.00 |

| ST-EU-13540 | 13.5 | 4.00 | w | 2.70 | 25.00 | 0.00 |

| Part No. | L/mm | L/inch | W/mm | W/inch | T/mm | T/inch |

|---|---|---|---|---|---|---|

| ST-US-I-250-062 | 6.35 | 0.250 | 1.27 to 12.70 | 0.050 to 0.500 | 1.57 | 0.062 |

| ST-US-I-281-078 | 7.14 | 0.281 | 1.27 to 12.70 | 0.050 to 0.500 | 1.98 | 0.078 |

| ST-US-I-281-093 | 7.14 | 0.281 | 1.27 to 12.70 | 0.050 to 0.500 | 2.36 | 0.093 |

| ST-US-I-321-093 | 7.92 | 0.321 | 1.27 to 20.32 | 0.050 to 0.800 | 2.36 | 0.093 |

| ST-US-I-375-093 | 9.53 | 0.375 | 1.27 to 20.32 | 0.050 to 0.800 | 2.36 | 0.093 |

| ST-US-I-500-125 | 12.70 | 0.500 | 1.27 to 20.32 | 0.050 to 0.800 | 3.18 | 0.125 |

| ST-US-I-375-125 | 9.53 | 0.375 | 1.27 to 20.32 | 0.050 to 0.800 | 3.18 | 0.125 |

| ST-US-I-344-125 | 8.74 | 0.344 | 1.27 to 20.32 | 0.050 to 0.800 | 3.18 | 0.125 |

| ST-US-I-375-156 | 9.53 | 0.375 | 1.27 to 20.32 | 0.050 to 0.800 | 3.96 | 0.156 |

| Part No. | L/mm | L/inch | W/mm | W/inch | T/mm | T/inch |

|---|---|---|---|---|---|---|

| ST-US-II-281-078 | 7.14 | 0.281 | 1.27 to 12.70 | 0.050 to 0.500 | 1.98 | 0.078 |

| ST-US-II-312-093 | 7.92 | 0.312 | 1.27 to 12.70 | 0.050 to 0.500 | 2.36 | 0.093 |

| ST-US-II-375-093 | 9.53 | 0.375 | 1.27 to 12.70 | 0.050 to 0.500 | 2.36 | 0.093 |

| ST-US-II-500-125 | 12.70 | 0.500 | 1.27 to 20.32 | 0.050 to 0.800 | 3.18 | 0.125 |

| ST-US-II-375-125 | 9.53 | 0.375 | 1.27 to 20.32 | 0.050 to 0.800 | 3.18 | 0.125 |

| ST-US-II-344-125 | 8.74 | 0.344 | 1.27 to 20.32 | 0.050 to 0.800 | 3.18 | 0.125 |

| Part No. | L/mm | L/inch | W/mm | W/inch | T/mm | T/inch |

|---|---|---|---|---|---|---|

| ST-US-III-250-062 | 6.35 | 0.250 | 1.65 to 5.46 | 0.065 to 0.215 | 1.57 | 0.062 |

| ST-US-III-281-078 | 7.14 | 0.281 | 2.16 to 7.92 | 0.085 to 0.312 | 1.98 | 0.078 |

| ST-US-III-281-093 | 7.14 | 0.281 | 2.54 to 6.35 | 0.100 to 0.250 | 2.36 | 0.093 |

| ST-US-III-321-093 | 7.92 | 0.321 | 2.54 to 7.92 | 0.100 to 0.312 | 2.36 | 0.093 |

| ST-US-III-375-093 | 9.53 | 0.375 | 3.81 to 9.53 | 0.150 to 0.375 | 2.36 | 0.093 |

| ST-US-III-500-125 | 12.70 | 0.500 | 3.81 to 9.53 | 0.150 to 0.375 | 3.18 | 0.125 |

| ST-US-III-375-125 | 9.53 | 0.375 | 3.81 to 19.05 | 0.150 to 0.750 | 3.18 | 0.125 |

| ST-US-III-344-125 | 8.74 | 0.344 | 3.18 to 7.62 | 0.125 to 0.300 | 3.18 | 0.125 |

| ST-US-III-375-156 | 9.53 | 0.375 | 4.32 to 9.53 | 0.170 to 0.375 | 3.96 | 0.156 |

| Part No. | L/mm | S/mm | α1° | α2° | R/mm |

|---|---|---|---|---|---|

| ST-A-6019 | 6.0 | 1.90 | 30 | 45.00 | 0.95 |

| ST-A-8338 | 8.3 | 3.80 | 30 | / | 1.90 |

| ST-A-6020 | 6.0 | 2.00 | 27.47 | / | 2-0.5*45° |

| ST-A-6319 | 6.3 | 1.90 | 38 | / | 0.95 |

| ST-A-6120 | 6.1 | 2.00 | 34 | / | 1.00 |

| ST-A-6519 | 6.5 | 1.90 | 24 | 38.00 | 0.95 |

| ST-A-6522 | 6.5 | 2.20 | 42.36 | / | 0.80 |

The width (W) can be customized according to your needs

| Part No. | L/mm | S/mm | α° | β° | L1/mm | R/mm |

|---|---|---|---|---|---|---|

| ST-B-3015-60-113 | 3.0 | 1.50 | 60 | 11.30 | 1.00 | 0.50 |

| ST-B-3016-60-113 | 3.0 | 1.60 | 60 | 11.30 | 1.00 | 0.50 |

| ST-B-3018-60-113 | 3.0 | 1.80 | 60 | 11.30 | 1.00 | 0.50 |

| ST-B-4014-60-11 | 4.0 | 1.40 | 60 | 11.00 | 1.00 | 0.50 |

| ST-B-4018-60-11 | 4.0 | 1.80 | 60 | 11.00 | 1.00 | 0.50 |

| ST-B-4314-63-15 | 4.3 | 1.40 | 63 | 15.00 | 1.40 | 0.50 |

| ST-B-4514-60-20 | 4.5 | 1.40 | 60 | 20.00 | 1.00 | 0.50 |

| ST-B-4514-65-20 | 4.5 | 1.40 | 65 | 20.00 | 1.00 | 0.50 |

| ST-B-4514-70-20 | 4.5 | 1.40 | 70 | 20.00 | 1.00 | 0.50 |

| ST-B-4515-60-20 | 4.5 | 1.50 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-4515-60-27 | 4.5 | 1.50 | 60 | 27.00 | 1.00 | 0.50 |

| ST-B-4515-62-36 | 4.5 | 1.50 | 62 | 36.00 | 0.85 | 0.60 |

| ST-B-4515-62-45 | 4.5 | 1.50 | 62 | 45.00 | 1.50 | 0.50 |

| ST-B-4515-75-20 | 4.5 | 1.50 | 75 | 20.00 | 1.37 | 0.50 |

| ST-B-4517-65-20 | 4.5 | 1.70 | 65 | 20.00 | 1.50 | 0.30 |

| ST-B-4520-75-17 | 4.5 | 2.00 | 75 | 17.00 | 1.60 | 0.50 |

| ST-B-4614-65-20 | 4.6 | 1.40 | 65 | 20.00 | 1.00 | 0.50 |

| ST-B-4615-60-27 | 4.6 | 1.50 | 60 | 27.00 | 1.00 | 0.50 |

| ST-B-4714-60-20 | 4.7 | 1.40 | 60 | 20.00 | 1.55 | 0.50 |

| ST-B-4714-65-20 | 4.7 | 1.40 | 65 | 20.00 | 1.00 | 0.50 |

| ST-B-4714-65-265 | 4.7 | 1.40 | 65 | 26.50 | 1.00 | 0.50 |

| ST-B-4715-65-265 | 4.7 | 1.50 | 65 | 26.50 | 1.00 | 0.50 |

| ST-B-4716-65-265 | 4.7 | 1.60 | 65 | 26.50 | 1.00 | 0.50 |

| ST-B-4814-65-20 | 4.8 | 1.40 | 65 | 20.00 | 1.51 | 0.50 |

| ST-B-4815-59-1269 | 4.8 | 1.50 | 59 | 12.69 | 2.00 | 0.50 |

| ST-B-4815-60-20 | 4.8 | 1.50 | 60 | 20.00 | 1.00 | 0.50 |

| ST-B-4815-60-20 | 4.8 | 1.50 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-4815-63-20 | 4.8 | 1.50 | 63 | 20.00 | 1.40 | 0.50 |

| ST-B-4815-65-11 | 4.8 | 1.50 | 65 | 11.00 | 1.50 | 0.50 |

| ST-B-4816-45-55 | 4.8 | 1.60 | 45 | 55.00 | 0.42 | 0.50 |

| ST-B-4816-60-32 | 4.8 | 1.60 | 60 | 32.00 | 0.80 | 0.50 |

| ST-B-4816-65-20 | 4.8 | 1.60 | 65 | 20.00 | 1.79 | 0.40 |

| ST-B-5014-65-11 | 5.0 | 1.40 | 65 | 11.00 | 1.50 | 0.50 |

| ST-B-5014-65-20 | 5.0 | 1.40 | 65 | 20.00 | 1.51 | 0.30 |

| ST-B-50153-55-20 | 5.0 | 1.53 | 55 | 20.00 | 1.37 | 0.50 |

| ST-B-5015-55-15 | 5.0 | 1.50 | 55 | 15.00 | 1.49 | 0.30 |

| ST-B-5015-60-15 | 5.0 | 1.50 | 60 | 15.00 | 1.50 | 0.50 |

| ST-B-5015-60-19 | 5.0 | 1.50 | 60 | 19.00 | 1.50 | 0.50 |

| ST-B-5015-60-20R45 | 5.0 | 1.50 | 60 | 20.00 | 1.10 | 0.5*45° |

| ST-B-5015-60-20 | 5.0 | 1.50 | 60 | 20.00 | 1.10 | 0.50 |

| ST-B-5015-60-22 | 5.0 | 1.50 | 60 | 22.00 | 1.20 | 0.50 |

| ST-B-5015-62-25 | 5.0 | 1.50 | 62 | 25.00 | 1.07 | 0.50 |

| ST-B-5015-70-20R45 | 5.0 | 1.50 | 70 | 20.00 | 1.10 | 0.5*45° |

| ST-B-5015-70-20 | 5.0 | 1.50 | 70 | 20.00 | 1.10 | 0.50 |

| ST-B-5015-70-20L | 5.0 | 1.50 | 70 | 20.00 | 1.50 | 0.50 |

| ST-B-5015-73-18 | 5.0 | 1.50 | 73 | 18.00 | 2.00 | 0.50 |

| ST-B-50165-65-20 | 5.0 | 1.65 | 65 | 20.00 | 1.37 | 0.60 |

| ST-B-5016-60-14 | 5.0 | 1.60 | 60 | 14.00 | 2.00 | 0.50 |

| ST-B-5016-60-20 | 5.0 | 1.60 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5016-595-25 | 5.0 | 1.60 | 59.5 | 25.00 | 1.07 | 0.50 |

| ST-B-5016-62-18 | 5.0 | 1.60 | 62 | 18.00 | 1.50 | 0.50 |

| ST-B-5016-65-20 | 5.0 | 1.60 | 65 | 20.00 | 1.79 | 0.40 |

| ST-B-5016-70-20 | 5.0 | 1.60 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5016-70-20L | 5.0 | 1.60 | 70 | 20.00 | 1.90 | 0.50 |

| ST-B-5016-75-20 | 5.0 | 1.60 | 75 | 20.00 | 1.37 | 0.50 |

| ST-B-5017-60-20 | 5.0 | 1.70 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5017-62-18 | 5.0 | 1.70 | 62 | 18.00 | 1.50 | 0.50 |

| ST-B-5017-65-20 | 5.0 | 1.70 | 65 | 20.00 | 1.92 | 0.40 |

| ST-B-5017-72-27 | 5.0 | 1.70 | 72 | 27.00 | 1.20 | 0.50 |

| ST-B-5017-75-15 | 5.0 | 1.70 | 75 | 15.00 | 1.20 | 0.50 |

| ST-B-5018-70-20 | 5.0 | 1.80 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5020-75-30R45 | 5.0 | 2.00 | 75 | 30.00 | 0.87 | 0.5*45° |

| ST-B-5216-60-20 | 5.2 | 1.60 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5216-65-20 | 5.2 | 1.60 | 65 | 20.00 | 1.79 | 0.40 |

| ST-B-5216-70-20 | 5.2 | 1.60 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5217-60-20 | 5.2 | 1.70 | 60 | 20.00 | 1.10 | 0.50 |

| ST-B-5217-70-20 | 5.2 | 1.70 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5315-60-20 | 5.3 | 1.50 | 60 | 20.00 | 1.10 | 0.50 |

| ST-B-5315-60-20L1 | 5.3 | 1.50 | 60 | 20.00 | 1.30 | 0.50 |

| ST-B-5315-60-20L2 | 5.3 | 1.50 | 60 | 20.00 | 1.90 | 0.50 |

| ST-B-5315-75-20 | 5.3 | 1.50 | 75 | 20.00 | 1.10 | 0.50 |

| ST-B-5316-60-20 | 5.3 | 1.60 | 60 | 20.00 | 1.90 | 0.50 |

| ST-B-5316-60-25 | 5.3 | 1.60 | 60 | 25.00 | 1.07 | 0.50 |

| ST-B-5316-63-20 | 5.3 | 1.60 | 63 | 20.00 | 1.60 | 0.50 |

| ST-B-5316-65-20 | 5.3 | 1.60 | 65 | 20.00 | 0.70 | 0.50 |

| ST-B-5316-65-20L | 5.3 | 1.60 | 65 | 20.00 | 1.79 | 0.40 |

| ST-B-5316-70-20 | 5.3 | 1.60 | 70 | 20.00 | 1.10 | 0.50 |

| ST-B-5317-70-45 | 5.3 | 1.70 | 70 | 45.00 | 0.80 | 0.50 |

| ST-B-5318-65-20 | 5.3 | 1.80 | 65 | 20.00 | 1.92 | 0.40 |

| ST-B-5417-60-20 | 5.4 | 1.70 | 60 | 20.00 | 1.31 | 0.50 |

| ST-B-5417-70-20 | 5.4 | 1.70 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5515-62-20 | 5.5 | 1.50 | 62 | 20.00 | 1.10 | 0.50 |

| ST-B-5515-65-15 | 5.5 | 1.50 | 65 | 15.00 | 1.50 | 0.50 |

| ST-B-5516-60-14 | 5.5 | 1.60 | 60 | 14.00 | 1.60 | 0.50 |

| ST-B-5516-60-20 | 5.5 | 1.60 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5516-60-2125 | 5.5 | 1.60 | 60 | 21.25 | 1.80 | 0.50 |

| ST-B-5516-60-25 | 5.5 | 1.60 | 60 | 25.00 | 1.07 | 0.50 |

| ST-B-5516-62-18 | 5.5 | 1.60 | 62 | 18.00 | 1.65 | 0.50 |

| ST-B-5516-70-14 | 5.5 | 1.60 | 70 | 14.00 | 1.60 | 0.50 |

| ST-B-5516-70-20 | 5.5 | 1.60 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5516-70-20LR45 | 5.5 | 1.60 | 70 | 20.00 | 1.51 | 0.5*45° |

| ST-B-5517-60-17 | 5.5 | 1.70 | 60 | 17.00 | 1.70 | 0.50 |

| ST-B-5517-60-18 | 5.5 | 1.70 | 60 | 18.00 | 2.00 | 0.50 |

| ST-B-5517-60-20LR | 5.5 | 1.70 | 60 | 20.00 | 1.37 | 0.60 |

| ST-B-5517-60-20L | 5.5 | 1.70 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5517-60-20 | 5.5 | 1.70 | 60 | 20.00 | 1.90 | 0.50 |

| ST-B-5517-60-21 | 5.5 | 1.70 | 60 | 21.00 | 1.80 | 0.50 |

| ST-B-5517-60-21L | 5.5 | 1.70 | 60 | 21.00 | 2.00 | 0.50 |

| ST-B-5517-60-25 | 5.5 | 1.70 | 60 | 25.00 | 1.29 | 0.50 |

| ST-B-5517-62-16 | 5.5 | 1.70 | 62 | 16.00 | 1.70 | 0.50 |

| ST-B-5517-62-168 | 5.5 | 1.70 | 62 | 16.80 | 1.65 | 0.50 |

| ST-B-5517-65-20 | 5.5 | 1.70 | 65 | 20.00 | 1.80 | 0.50 |

| ST-B-5517-65-21 | 5.5 | 1.70 | 65 | 21.00 | 2.00 | 0.50 |

| ST-B-5517-75-20 | 5.5 | 1.70 | 75 | 20.00 | 1.37 | 0.50 |

| ST-B-5518-58-1963 | 5.5 | 1.80 | 58 | 19.63 | 2.00 | 0.50 |

| ST-B-5518-60-20 | 5.5 | 1.80 | 60 | 20.00 | 1.30 | 0.50 |

| ST-B-5518-60-25 | 5.5 | 1.80 | 60 | 25.00 | 1.29 | 0.50 |

| ST-B-5518-60-29 | 5.5 | 1.80 | 60 | 29.00 | 1.10 | 0.50 |

| ST-B-5518-62-18 | 5.5 | 1.80 | 62 | 18.00 | 2.20 | 0.50 |

| ST-B-5518-70-20 | 5.5 | 1.80 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-55185-70-20 | 5.5 | 1.85 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5518-75-18 | 5.5 | 1.80 | 75 | 18.00 | 1.80 | 0.50 |

| ST-B-5518-75-20 | 5.5 | 1.80 | 75 | 20.00 | 1.65 | 0.50 |

| ST-B-5520-60-20 | 5.5 | 2.00 | 60 | 20.00 | 1.37 | 0.60 |

| ST-B-5520-62-25 | 5.5 | 2.00 | 62 | 25.00 | 1.30 | 0.50 |

| ST-B-5520-70-20 | 5.5 | 2.00 | 70 | 20.00 | 1.50 | 0.50 |

| ST-B-5524-60-20 | 5.5 | 2.40 | 60 | 20.00 | 1.37 | 0.60 |

| ST-B-5716-60-20R45 | 5.7 | 1.60 | 60 | 20.00 | 1.40 | 0.5*45° |

| ST-B-5716-60-20 | 5.7 | 1.60 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5716-60-218 | 5.7 | 1.60 | 60 | 21.80 | 0.50 | 0.50 |

| ST-B-5717-60-20 | 5.7 | 1.70 | 60 | 20.00 | 1.37 | 0.60 |

| ST-B-5717-62-20 | 5.7 | 1.70 | 62 | 20.00 | 1.60 | 0.50 |

| ST-B-5717-70-20R45 | 5.7 | 1.70 | 70 | 20.00 | 1.37 | 0.5*45° |

| ST-B-5718-65-20 | 5.7 | 1.80 | 65 | 20.00 | 1.92 | 0.40 |

| ST-B-5722-60-20 | 5.7 | 2.20 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5816-60-18 | 5.8 | 1.60 | 60 | 18.00 | 1.80 | 0.50 |

| ST-B-5816-65-265 | 5.8 | 1.60 | 65 | 26.50 | 1.00 | 0.50 |

| ST-B-5817-60-20 | 5.8 | 1.70 | 60 | 20.00 | 1.90 | 0.50 |

| ST-B-5817-60-218 | 5.8 | 1.70 | 60 | 21.80 | 2.00 | 0.50 |

| ST-B-5817-70-20 | 5.8 | 1.70 | 70 | 20.00 | 1.37 | 0.50 |

| ST-B-5818-60-15 | 5.8 | 1.80 | 60 | 15.00 | 1.38 | 0.50 |

| ST-B-5818-60-15L | 5.8 | 1.80 | 60 | 15.00 | 2.80 | 0.50 |

| ST-B-5818-60-20 | 5.8 | 1.80 | 60 | 20.00 | 1.20 | 0.50 |

| ST-B-5818-60-20L | 5.8 | 1.80 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-5818-60-45 | 5.8 | 1.80 | 60 | 45.00 | 0.75 | 0.40 |

| ST-B-5818-70-20 | 5.8 | 1.80 | 70 | 20.00 | 1.40 | 0.50 |

| ST-B-5818-70-25 | 5.8 | 1.80 | 70 | 25.00 | 1.60 | 0.50 |

| ST-B-5819-60-25 | 5.8 | 1.90 | 60 | 25.00 | 1.60 | 0.50 |

| ST-B-5820-65-20 | 5.8 | 2.00 | 65 | 20.00 | 1.90 | 0.50 |

| ST-B-60165-65-20 | 6.0 | 1.65 | 65 | 20.00 | 1.37 | 0.60 |

| ST-B-6016-60-20 | 6.0 | 1.60 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6016-62-14 | 6.0 | 1.60 | 62 | 14.00 | 2.40 | 0.50 |

| ST-B-6016-62-20R45 | 6.0 | 1.60 | 62 | 20.00 | 1.65 | 0.5*45° |

| ST-B-6017-60-14 | 6.0 | 1.70 | 60 | 14.00 | 2.00 | 0.50 |

| ST-B-6017-60-20 | 6.0 | 1.70 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6017-60-2076 | 6.0 | 1.70 | 60 | 20.76 | 2.20 | 0.50 |

| ST-B-6017-70-14 | 6.0 | 1.70 | 70 | 14.00 | 2.00 | 0.50 |

| ST-B-6018-60-20 | 6.0 | 1.80 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6018-60-20R45 | 6.0 | 1.80 | 60 | 20.00 | 1.40 | 0.5*45° |

| ST-B-6018-60-20L | 6.0 | 1.80 | 60 | 20.00 | 1.65 | 0.60 |

| ST-B-6018-60-20LR | 6.0 | 1.80 | 60 | 20.00 | 1.65 | 0.50 |

| ST-B-6018-60-24 | 6.0 | 1.80 | 60 | 24.00 | 1.80 | 0.50 |

| ST-B-6018-62-16 | 6.0 | 1.80 | 62 | 16.00 | 2.40 | 0.50 |

| ST-B-6018-65-20 | 6.0 | 1.80 | 65 | 20.00 | 2.50 | 0.50 |

| ST-B-6018-65-24 | 6.0 | 1.80 | 65 | 24.00 | 1.80 | 0.50 |

| ST-B-6018-65-19 | 6.0 | 1.80 | 65 | 19.00 | 2.00 | 0.50 |

| ST-B-6018-70-19 | 6.0 | 1.80 | 70 | 19.00 | 2.00 | 0.50 |

| ST-B-6018-70-20 | 6.0 | 1.80 | 70 | 20.00 | 1.50 | 0.50 |

| ST-B-6018-75-20 | 6.0 | 1.80 | 75 | 20.00 | 1.65 | 0.50 |

| ST-B-6019-60-17 | 6.0 | 1.90 | 60 | 17.00 | 2.00 | 0.50 |

| ST-B-6019-70-17 | 6.0 | 1.90 | 70 | 17.00 | 2.00 | 0.50 |

| ST-B-6020-60-17 | 6.0 | 2.00 | 60 | 17.00 | 2.30 | 0.50 |

| ST-B-6020-60-20 | 6.0 | 2.00 | 60 | 20.00 | 1.30 | 0.50 |

| ST-B-6020-60-20L | 6.0 | 2.00 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6020-60-20L2 | 6.0 | 2.00 | 60 | 20.00 | 1.80 | 0.50 |

| ST-B-6020-62-18 | 6.0 | 2.00 | 62 | 18.00 | 2.40 | 0.50 |

| ST-B-6020-62-20 | 6.0 | 2.00 | 62 | 20.00 | 2.42 | 0.50 |

| ST-B-6020-65-18 | 6.0 | 2.00 | 65 | 18.00 | 2.40 | 0.50 |

| ST-B-6020-68-30R45 | 6.0 | 2.00 | 68 | 30.00 | 1.04 | 0.5*45° |

| ST-B-6020-70-13 | 6.0 | 2.00 | 70 | 13.00 | 2.50 | 0.50 |

| ST-B-6020-70-20 | 6.0 | 2.00 | 70 | 20.00 | 1.60 | 0.50 |

| ST-B-6022-60-19 | 6.0 | 2.20 | 60 | 19.00 | 2.03 | 0.50 |

| ST-B-6022-75-20 | 6.0 | 2.20 | 75 | 20.00 | 1.40 | 0.50 |

| ST-B-6025-55-218R45 | 6.0 | 2.50 | 55 | 21.80 | 2.00 | 0.6*45° |

The width (W) can be customized according to your needs

| Part No. | L/mm | S/mm | α° | β° | L1/mm | R/mm |

|---|---|---|---|---|---|---|

| ST-B-6028-65-25 | 6.0 | 2.80 | 65 | 25.00 | 1.50 | 0.50 |

| ST-B-6030-65-25 | 6.0 | 3.00 | 65 | 25.00 | 1.50 | 0.50 |

| ST-B-6032-65-25 | 6.0 | 3.20 | 65 | 25.00 | 1.50 | 0.50 |

| ST-B-6218-62-15 | 6.2 | 1.80 | 62 | 15.00 | 2.60 | 0.50 |

| ST-B-6219-60-20 | 6.2 | 1.90 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6219-60-20L | 6.2 | 1.90 | 60 | 20.00 | 1.65 | 0.50 |

| ST-B-6220-60-20 | 6.2 | 2.00 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6318-60-20 | 6.3 | 1.80 | 60 | 20.00 | 2.00 | 0.50 |

| ST-B-6319-61-1918 | 6.3 | 1.90 | 61 | 19.18 | 2.30 | 0.50 |

| ST-B-6320-57-23 | 6.3 | 2.00 | 57 | 23.00 | 1.65 | 0.50 |

| ST-B-6320-70-20 | 6.3 | 2.00 | 70 | 20.00 | 1.90 | 0.50 |

| ST-B-6518-60-20 | 6.5 | 1.80 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6520-60-19 | 6.5 | 2.00 | 60 | 19.00 | 2.03 | 0.50 |

| ST-B-6520-60-24 | 6.5 | 2.00 | 60 | 24.00 | 1.80 | 0.50 |

| ST-B-6520-62-17 | 6.5 | 2.00 | 62 | 17.00 | 2.30 | 0.50 |

| ST-B-6520-62-17 | 6.5 | 2.00 | 62 | 17.00 | 2.60 | 0.50 |

| ST-B-6520-70-17 | 6.5 | 2.00 | 70 | 17.00 | 2.30 | 0.50 |

| ST-B-6520-70-20L | 6.5 | 2.00 | 70 | 20.00 | 1.10 | 0.50 |

| ST-B-6520-70-20 | 6.5 | 2.00 | 70 | 20.00 | 1.60 | 0.50 |

| ST-B-6520-70-20R45 | 6.5 | 2.00 | 70 | 20.00 | 1.60 | 0.5*45° |

| ST-B-6520-70-20L2 | 6.5 | 2.00 | 70 | 20.00 | 1.92 | 0.50 |

| ST-B-65205-70-20 | 6.5 | 2.05 | 70 | 20.00 | 1.92 | 0.50 |

| ST-B-6520-70-25 | 6.5 | 2.00 | 70 | 25.00 | 1.50 | 0.50 |

| ST-B-6521-60-20 | 6.5 | 2.10 | 60 | 20.00 | 2.50 | 0.50 |

| ST-B-6521-60-32 | 6.5 | 2.10 | 60 | 32.00 | 1.25 | 0.50 |

| ST-B-6521-68-17 | 6.5 | 2.10 | 68 | 17.00 | 2.50 | 0.50 |

| ST-B-6521-70-20 | 6.5 | 2.10 | 70 | 20.00 | 1.60 | 0.50 |

| ST-B-6521-70-20L | 6.5 | 2.10 | 70 | 20.00 | 1.92 | 0.50 |

| ST-B-6522-60-20 | 6.5 | 2.20 | 60 | 20.00 | 1.60 | 0.50 |

| ST-B-6522-60-22 | 6.5 | 2.20 | 60 | 22.00 | 2.50 | 0.50 |

| ST-B-6522-60-24 | 6.5 | 2.20 | 60 | 24.00 | 2.00 | 0.50 |

| ST-B-6522-65-14 | 6.5 | 2.20 | 65 | 14.00 | 2.80 | 0.50 |

| ST-B-6523-65-17 | 6.5 | 2.30 | 65 | 17.00 | 2.50 | 0.50 |

| ST-B-6524-70-20 | 6.5 | 2.40 | 70 | 20.00 | 1.60 | 0.50 |

| ST-B-6526-70-28 | 6.5 | 2.60 | 70 | 28.00 | 2.40 | 0.50 |

| ST-B-6622-60-25 | 6.6 | 2.20 | 60 | 25.00 | 1.93 | 0.50 |

| ST-B-6718-60-20 | 6.7 | 1.80 | 60 | 20.00 | 1.40 | 0.50 |

| ST-B-6720-60-20 | 6.7 | 2.00 | 60 | 20.00 | 1.60 | 0.50 |

| ST-B-6720-65-20 | 6.7 | 2.00 | 65 | 20.00 | 2.15 | 0.50 |

| ST-B-6820-62-45 | 6.8 | 2.00 | 62 | 45.00 | 0.80 | 0.50 |

| ST-B-6820-65-20 | 6.8 | 2.00 | 65 | 20.00 | 1.92 | 0.50 |

| ST-B-6822-65-20 | 6.8 | 2.20 | 65 | 20.00 | 1.40 | 0.50 |

| ST-B-6825-60-316 | 6.8 | 2.50 | 60 | 31.60 | 1.30 | 0.50 |

| ST-B-7016-62-16 | 7.0 | 1.60 | 62 | 16.00 | 3.50 | 0.50 |

| ST-B-7018-60-20 | 7.0 | 1.80 | 60 | 20.00 | 1.37 | 0.50 |

| ST-B-7018-60-20LR45 | 7.0 | 1.80 | 60 | 20.00 | 1.65 | 0.5*45° |

| ST-B-70205-70-23 | 7.0 | 2.05 | 70 | 23.00 | 1.80 | 0.50 |

| ST-B-7020-60-20 | 7.0 | 2.00 | 60 | 20.00 | 1.60 | 0.50 |

| ST-B-7020-60-24 | 7.0 | 2.00 | 60 | 24.00 | 2.00 | 0.50 |

| ST-B-7020-60-28 | 7.0 | 2.00 | 60 | 28.00 | 1.50 | 0.50 |

| ST-B-7020-62-45 | 7.0 | 2.00 | 62 | 45.00 | 0.80 | 0.50 |

| ST-B-7020-65-15R45 | 7.0 | 2.00 | 65 | 15.00 | 3.00 | 0.5*45° |

| ST-B-7020-65-20 | 7.0 | 2.00 | 65 | 20.00 | 2.15 | 0.50 |

| ST-B-7021-57-23 | 7.0 | 2.10 | 57 | 23.00 | 1.88 | 0.50 |

| ST-B-7021-60-20 | 7.0 | 2.10 | 60 | 20.00 | 2.20 | 0.50 |

| ST-B-7021-60-24 | 7.0 | 2.10 | 60 | 24.00 | 1.90 | 0.50 |

| ST-B-7021-62-17 | 7.0 | 2.10 | 62 | 17.00 | 3.00 | 0.50 |

| ST-B-7021-62-20 | 7.0 | 2.10 | 62 | 20.00 | 1.10 | 0.50 |

| ST-B-7022-57-23 | 7.0 | 2.20 | 57 | 23.00 | 1.88 | 0.50 |

| ST-B-7022-60-20 | 7.0 | 2.20 | 60 | 20.00 | 2.20 | 0.80 |

| ST-B-7022-60-20L | 7.0 | 2.20 | 60 | 20.00 | 2.80 | 0.50 |

| ST-B-7022-62-20 | 7.0 | 2.20 | 62 | 20.00 | 1.10 | 0.50 |

| ST-B-7022-62-20R45 | 7.0 | 2.20 | 62 | 20.00 | 2.01 | 0.5*45° |

| ST-B-7022-70-20 | 7.0 | 2.20 | 70 | 20.00 | 2.02 | 0.50 |

| ST-B-7023-57-23 | 7.0 | 2.30 | 57 | 23.00 | 1.88 | 0.50 |

| ST-B-7023-60-20 | 7.0 | 2.30 | 60 | 20.00 | 1.60 | 0.50 |

| ST-B-7023-60-20L | 7.0 | 2.30 | 60 | 20.00 | 2.15 | 0.50 |

| ST-B-7023-60-25 | 7.0 | 2.30 | 60 | 25.00 | 2.14 | 0.50 |

| ST-B-7023-62-20R45 | 7.0 | 2.30 | 62 | 20.00 | 2.47 | 0.5*45° |

| ST-B-7023-62-20 | 7.0 | 2.30 | 62 | 20.00 | 2.90 | 0.50 |

| ST-B-7023-65-20 | 7.0 | 2.30 | 65 | 20.00 | 2.50 | 0.50 |

| ST-B-7023-70-20 | 7.0 | 2.30 | 70 | 20.00 | 1.60 | 0.50 |

| ST-B-7025-60-32 | 7.0 | 2.50 | 60 | 32.00 | 1.30 | 0.50 |

| ST-B-7025-62-19 | 7.0 | 2.50 | 62 | 19.00 | 3.50 | 0.50 |

| ST-B-7025-65-22 | 7.0 | 2.50 | 65 | 22.00 | 2.50 | 0.50 |

| ST-B-7025-70-20 | 7.0 | 2.50 | 70 | 20.00 | 1.80 | 0.50 |

| ST-B-7025-67-286 | 7.0 | 2.50 | 67 | 28.60 | 2.20 | 0.30 |

| ST-B-7030-60-30 | 7.0 | 3.00 | 60 | 30.00 | 1.39 | 0.50 |

| ST-B-7030-80-20R45 | 7.0 | 3.00 | 80 | 20.00 | 3.30 | 0.5*45° |

| ST-B-7030-80-40R45 | 7.0 | 3.00 | 80 | 40.00 | 1.40 | 0.5*45° |

| ST-B-7220-65-25 | 7.2 | 2.00 | 65 | 25.00 | 2.14 | 0.50 |

| ST-B-7222-65-25R45 | 7.2 | 2.20 | 65 | 25.00 | 2.14 | 0.5*45° |

| ST-B-7424-65-25 | 7.4 | 2.40 | 65 | 25.00 | 2.36 | 0.50 |

| ST-B-7520-62-45 | 7.5 | 2.00 | 62 | 45.00 | 0.70 | 0.50 |

| ST-B-7522-60-20 | 7.5 | 2.20 | 60 | 20.00 | 1.80 | 0.50 |

| ST-B-7522-70-16 | 7.5 | 2.20 | 70 | 16.00 | 2.44 | 0.50 |

| ST-B-7523-60-18 | 7.5 | 2.30 | 60 | 18.00 | 3.00 | 0.50 |

| ST-B-7523-60-20 | 7.5 | 2.30 | 60 | 20.00 | 2.80 | 0.50 |

| ST-B-7523-65-27 | 7.5 | 2.30 | 65 | 27.00 | 2.50 | 0.50 |

| ST-B-7524-60-27 | 7.5 | 2.40 | 60 | 27.00 | 2.16 | 0.50 |

| ST-B-7525-65-24 | 7.5 | 2.50 | 65 | 24.00 | 2.50 | 0.50 |

| ST-B-7525-65-30 | 7.5 | 2.50 | 65 | 30.00 | 1.73 | 0.50 |

| ST-B-7822-60-20 | 7.8 | 2.20 | 60 | 20.00 | 2.20 | 0.50 |

| ST-B-7822-60-24 | 7.8 | 2.20 | 60 | 24.00 | 2.47 | 0.50 |

| ST-B-8022-60-16 | 8.0 | 2.20 | 60 | 16.00 | 2.44 | 0.50 |

| ST-B-8022-60-19 | 8.0 | 2.20 | 60 | 19.00 | 2.03 | 0.50 |

| ST-B-8022-65-22 | 8.0 | 2.20 | 65 | 22.00 | 2.00 | 0.50 |

| ST-B-8022-70-16 | 8.0 | 2.20 | 70 | 16.00 | 2.44 | 0.50 |

| ST-B-8022-70-19 | 8.0 | 2.20 | 70 | 19.00 | 2.03 | 0.50 |

| ST-B-8022-75-22 | 8.0 | 2.20 | 75 | 22.00 | 2.00 | 0.50 |

| ST-B-8023-60-20 | 8.0 | 2.30 | 60 | 20.00 | 2.00 | 0.50 |

| ST-B-8023-62-15 | 8.0 | 2.30 | 62 | 15.00 | 4.00 | 0.50 |

| ST-B-8023-62-34 | 8.0 | 2.30 | 62 | 34.00 | 1.19 | 0.50 |

| ST-B-8023-62-34LR | 8.0 | 2.30 | 62 | 34.00 | 1.40 | 1.00 |

| ST-B-8023-65-20 | 8.0 | 2.30 | 65 | 20.00 | 2.47 | 0.50 |

| ST-B-8025-60-22 | 8.0 | 2.50 | 60 | 22.00 | 2.50 | 0.50 |

| ST-B-8025-62-17 | 8.0 | 2.50 | 62 | 17.00 | 4.00 | 0.50 |

| ST-B-8025-62-20R45 | 8.0 | 2.50 | 62 | 20.00 | 2.61 | 0.5*45° |

| ST-B-8025-65-256 | 8.0 | 2.50 | 65 | 25.60 | 2.50 | 0.50 |

| ST-B-8028-60-327 | 8.0 | 2.80 | 60 | 32.70 | 1.40 | 0.50 |

| ST-B-8028-62-17 | 8.0 | 2.80 | 62 | 17.00 | 4.00 | 0.50 |

| ST-B-8028-62-20 | 8.0 | 2.80 | 62 | 20.00 | 2.61 | 0.50 |

| ST-B-8030-60-35R45 | 8.0 | 3.00 | 60 | 35.00 | 1.43 | 0.5*45° |

| ST-B-8223-62-25 | 8.2 | 2.30 | 62 | 25.00 | 1.50 | 0.50 |

| ST-B-8520-62-25 | 8.5 | 2.00 | 62 | 25.00 | 1.50 | 0.50 |

| ST-B-8523-62-23 | 8.5 | 2.30 | 62 | 23.00 | 2.36 | 0.50 |

| ST-B-8523-62-25 | 8.5 | 2.30 | 62 | 25.00 | 1.50 | 0.50 |

| ST-B-8524-60-25 | 8.5 | 2.40 | 60 | 25.00 | 1.71 | 0.50 |

| ST-B-8525-60-20 | 8.5 | 2.50 | 60 | 20.00 | 2.00 | 0.50 |

| ST-B-8525-60-25 | 8.5 | 2.50 | 60 | 25.00 | 3.00 | 0.50 |

| ST-B-8525-62-20R45 | 8.5 | 2.50 | 62 | 20.00 | 2.61 | 0.5*45° |

| ST-B-8525-62-20 | 8.5 | 2.50 | 62 | 20.00 | 3.02 | 0.50 |

| ST-B-8525-70-20 | 8.5 | 2.50 | 70 | 20.00 | 3.02 | 0.50 |

| ST-B-8528-62-20R45 | 8.5 | 2.80 | 62 | 20.00 | 2.61 | 1.0*45° |

| ST-B-8528-65-20 | 8.5 | 2.80 | 65 | 20.00 | 2.20 | 0.50 |

| ST-B-8528-70-10 | 8.5 | 2.80 | 70 | 10.00 | 2.50 | 1.25 |

| ST-B-8530-62-20 | 8.5 | 3.00 | 62 | 20.00 | 4.40 | 0.50 |

| ST-B-9021-57-23 | 9.0 | 2.10 | 57 | 23.00 | 1.65 | 0.50 |

| ST-B-9025-60-20 | 9.0 | 2.50 | 60 | 20.00 | 3.20 | 0.50 |

| ST-B-9025-70-33 | 9.0 | 2.50 | 70 | 33.00 | 1.60 | 0.50 |

| ST-B-9026-60-20 | 9.0 | 2.60 | 60 | 20.00 | 3.00 | 1.00 |

| ST-B-9027-66-20 | 9.0 | 2.70 | 66 | 20.00 | 3.19 | 0.50 |

| ST-B-9028-60-20 | 9.0 | 2.80 | 60 | 20.00 | 2.30 | 0.50 |

| ST-B-9028-70-10 | 9.0 | 2.80 | 70 | 10.00 | 2.50 | 1.25 |

| ST-B-9030-60-20 | 9.0 | 3.00 | 60 | 20.00 | 2.30 | 0.60 |

| ST-B-9030-60-30R45 | 9.0 | 3.00 | 60 | 30.00 | 1.39 | 0.5*45° |

| ST-B-9030-62-21 | 9.0 | 3.00 | 62 | 21.00 | 4.00 | 0.50 |

| ST-B-9226-60-25 | 9.2 | 2.60 | 60 | 25.00 | 1.93 | 0.50 |

| ST-B-9528-60-20 | 9.5 | 2.80 | 60 | 20.00 | 2.80 | 1.00 |

| ST-B-9530-60-20 | 9.5 | 3.00 | 60 | 20.00 | 3.10 | 0.50 |

| ST-B-9530-62-20 | 9.5 | 3.00 | 62 | 20.00 | 2.75 | 0.50 |

| ST-B-9830-60-20 | 9.8 | 3.00 | 60 | 20.00 | 2.80 | 0.50 |

| ST-B-10025-60-20 | 10.0 | 2.50 | 60 | 20.00 | 3.20 | 0.50 |

| ST-B-10028-60-20 | 10.0 | 2.80 | 60 | 20.00 | 3.10 | 0.50 |

| ST-B-10028-60-20L | 10.0 | 2.80 | 60 | 20.00 | 3.30 | 0.50 |

| ST-B-10028-62-20 | 10.0 | 2.80 | 62 | 20.00 | 2.75 | 0.50 |

| ST-B-10030-62-20R45 | 10.0 | 3.00 | 62 | 20.00 | 2.75 | 0.5*45° |

| ST-B-10525-62-45 | 10.5 | 2.50 | 62 | 45.00 | 1.20 | 0.50 |

| ST-B-10528-67-20 | 10.5 | 2.80 | 67 | 20.00 | 3.30 | 0.50 |

| ST-B-10528-70-20 | 10.5 | 2.80 | 70 | 20.00 | 3.57 | 0.80 |

| ST-B-10530-60-20 | 10.5 | 3.00 | 60 | 20.00 | 2.28 | 0.50 |

| ST-B-10530-60-25R45 | 10.5 | 3.00 | 60 | 25.00 | 3.22 | 0.5*45° |

| ST-B-10530-60-40 | 10.5 | 3.00 | 60 | 40.00 | 1.55 | 0.50 |

| ST-B-10535-60-20 | 10.5 | 3.50 | 60 | 20.00 | 2.80 | 0.50 |

| ST-B-10535-60-30 | 10.5 | 3.50 | 60 | 30.00 | 2.80 | 0.50 |

| ST-B-11028-70-18 | 11.0 | 2.80 | 70 | 18.00 | 4.00 | / |

| ST-B-11530-60-20 | 11.5 | 3.00 | 60 | 20.00 | 2.28 | 0.50 |

| ST-B-11535-60-20R45 | 11.5 | 3.50 | 60 | 20.00 | 5.50 | 0.5*45° |

| ST-B-12034-55-45 | 12.0 | 3.40 | 55 | 45.00 | 1.00 | 0.50 |

| ST-B-12040-62-45 | 12.0 | 4.00 | 62 | 45.00 | 2.00 | / |

| ST-B-12623-55-12 | 12.6 | 2.30 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12625-55-12 | 12.6 | 2.50 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12630-55-12 | 12.6 | 3.00 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12633-55-12 | 12.6 | 3.30 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12635-55-12 | 12.6 | 3.50 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12638-55-12 | 12.6 | 3.80 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12640-55-12 | 12.6 | 4.00 | 55 | 12.00 | 4.33 | 0.50 |

| ST-B-12642-55-12 | 12.6 | 4.20 | 55 | 12.00 | 4.33 | 1.00 |

| ST-B-12840-70-30 | 12.8 | 4.00 | 70 | 30.00 | 3.00 | 0.50 |

| ST-B-13040-60-30 | 13.0 | 4.00 | 60 | 30.00 | 3.00 | 0.50 |

| ST-B-13040-62-45 | 13.0 | 4.00 | 62 | 45.00 | 2.00 | / |

| ST-B-13040-76-266 | 13.0 | 4.00 | 76 | 26.60 | 1.80 | / |

| ST-B-14035-55-30 | 14.0 | 3.50 | 55 | 30.00 | 4.60 | 0.50 |

Grades for Tungsten Carbide Saw Tips

| Grade | ISO Code | Grain Size | Density {g/cm³} |

Hardness {HRA} |

TRS {N/mm} |

Application Recommendation |

|---|---|---|---|---|---|---|

| General Grades | ||||||

| YG6 | K20 | Medium | 14.85-15.05 | 91.0 | 2100 | For ordinary wood |

| YG8 | K30 | Medium | 14.60-14.85 | 90.0 | 2400 | For ordinary wood, also for aluminium |

| TC24S | K40 | Coarse | 14.50-14.80 | 88.5 | 2400 | For recycling wood, especially wood with some nails and stones |

| TM22 | K20 | Medium | 14.65-14.85 | 91.0 | 2200 | For hard wood, also for aluminium alloys |

| YG6X | K10 | Fine | 14.75-14.95 | 92.0 | 2000 | Specially for wood |

| YG8X | K10 | Fine | 14.60-14.85 | 91.5 | 2200 | For both wood and aluminium alloys |

| High-perperties Grades | ||||||

| TF30 | K10 | Fine | 14.70-14.85 | 92.0 | 3000 | Specially for hard wood |

| TF24 | K10 | Fine | 14.80-15.05 | 92.2 | 2400 | Specially for hard wood |

| TF30A | K20 | Fine | 14.60-14.80 | 91.5 | 3000 | Specially for aluminium alloys |

| TS30C | K05 | Submicron | 14.70-14.95 | 93.2 | ≥3000 | For high density wood and aluminium-plastic composite |

| TS30A | K10 | Submicron | 14.50-14.80 | 92.5 | ≥3000 | Specially for aluminium alloys |

| TS30S | K10 | Submicron | 14.25-14.55 | 92.0 | ≥3050 | For stone and aluminium alloys |

| TS20-1 | K10 | Submicron | 15.20-15.35 | 95.5 | ≥2000 | For plywood, density board and sandwich board |

| TS20-2 | K10 | Submicron | 15.10-15.25 | 95.5 | ≥2000 | For plywood, density board and sandwich board |

| TS20-3 | K01 | Submicron | 15.00-15.20 | 95.0 | ≥2000 | For particle board, laminated board, density board, and composite material |

| TS20-4 | K01 | Submicron | 14.90-15.10 | 94.5 | ≥2000 | For particle board, laminated board, density board, and composite material |

| TS24 | K10 | Submicron | 14.70-14.85 | 94.0 | ≥2400 | For plywood, density board and sandwich board |

| TS26 | K05 | Submicron | 14.90-15.10 | 93.6 | ≥2600 | For particle board, laminated board, density board, and composite material |

| TM22H | P40 | Medium | 12.80-13.30 | 90.0 | ≥2200 | For large saw blades |

| TM21 | M30 | Medium | 12.70-13.30 | 91.0 | ≥2100 | For the sawing of steels and stainless steels |

| TM20 | M20 | Medium | 12.85-13.35 | 91.5 | ≥2050 | For the sawing of cast iron and steel plates |

- Contact

Our team is ready to provide support

Truer Carbide is committed to providing efficient solutions to problems. Each team member has the expertise and experience to quickly understand and meet your needs.