When it comes to precision, durability, and efficiency in machining, carbide tools are the unsung heroes of the manufacturing world. Whether you’re shaping metal, carving wood, or drilling through tough materials, carbide tools are the go-to choice for professionals who demand the best. But what makes them so special? Why are they the preferred choice over traditional high-speed steel tools? And how can you ensure you’re getting the most out of your carbide tools?

Application Scenarios of Hard Alloy Cutting Tools

Carbide tools, also known as hard alloy cutting tools, are used in a wide range of industries. From automotive manufacturing to aerospace engineering, these tools are indispensable. Let’s break it down:

- Automotive Industry: Think about the precision required to craft engine components, gears, and brake systems. Carbide tools are used for milling, turning, and drilling these parts with unmatched accuracy.

- Aerospace Industry: When you’re dealing with materials like titanium or Inconel, you need a tool that can handle extreme heat and pressure. Carbide tools are up to the task, ensuring smooth finishes and tight tolerances.

- Woodworking: Yes, carbide tools aren’t just for metal! They’re also used in woodworking for cutting, shaping, and carving hardwoods.

- Medical Industry: Surgical instruments and implants require precision machining, and carbide tools deliver just that.

- Construction: Drilling through concrete or cutting through rebar? Carbide-tipped tools are your best bet.

In short, if it’s tough, precise, and needs to be done right, carbide tools are likely involved.

The Impact of Tool Life on Production Efficiency and Cost

Ever heard the saying, “Time is money”? Well, in manufacturing, tool life is money. The longer your carbide tools last, the fewer interruptions you’ll have in your production line. Here’s why tool life matters:

- Reduced Downtime: Frequent tool changes mean stopping production, which costs time and money. Carbide tools last significantly longer than traditional steel tools, keeping your production line running smoothly.

- Cost Savings: While carbide tools may have a higher upfront cost, their extended lifespan means you’ll save money in the long run. Fewer replacements = lower costs.

- Consistency: As tools wear down, the quality of your work can suffer. Carbide tools maintain their edge longer, ensuring consistent results throughout their lifespan.

So, if you’re looking to boost efficiency and cut costs, investing in high-quality carbide tools is a no-brainer.

Factors Affecting the Lifespan of Carbide Tools

Not all carbide tools are created equal, and their lifespan can vary depending on several factors. Here’s what you need to know:

- Material Being Machined: Harder materials like stainless steel or titanium will wear down tools faster than softer materials like aluminum.

- Cutting Speed and Feed Rate: Pushing your tools too hard can lead to premature wear. Finding the right balance is key.

- Coolant Usage: Proper cooling can significantly extend tool life by reducing heat buildup.

- Tool Geometry: The design of the tool, including its angles and coatings, plays a big role in how long it lasts.

- Operator Skill: Even the best tools can be ruined by improper use. Training your team is essential.

By understanding these factors, you can take steps to maximize the lifespan of your carbide tools.

How to Extend the Lifespan of Carbide Tools

| Tip | Explanation |

|---|---|

| Use the Right Cutting Parameters | Adjust speed, feed rate, and depth of cut to match the material and tool type. |

| Apply Coolant Properly | Reduce heat and friction to prevent tool wear. |

| Regularly Inspect Tools | Catch signs of wear early to avoid catastrophic failure. |

| Store Tools Correctly | Keep tools in a dry, organized environment to prevent damage. |

| Use High-Quality Carbide Tools | Invest in reputable brands and models for better performance and longevity. |

Common Types of Carbide Tool Wear and Corresponding Measures

| Type of Wear | Causes | Preventive Measures |

|---|---|---|

| Flank Wear | Friction between tool and workpiece | Use proper coolant and adjust cutting speed. |

| Crater Wear | High temperatures and chemical reactions | Choose tools with heat-resistant coatings. |

| Chipping | Impact or vibration during machining | Ensure stable setup and avoid excessive force. |

| Built-Up Edge | Material sticking to the tool | Increase cutting speed and use sharp tools. |

| Thermal Cracking | Rapid heating and cooling cycles | Maintain consistent coolant flow. |

Future Trends of Carbide in the Automotive Industry

The automotive industry is constantly evolving, and carbide tools are evolving with it. Here’s what’s on the horizon:

- Electric Vehicles (EVs): As EVs become more popular, the demand for lightweight materials like aluminum and composites is rising. Carbide tools are being adapted to handle these materials efficiently.

- Additive Manufacturing: 3D printing is changing how parts are made, and carbide tools are being used to finish and refine these components.

- Smart Tools: Imagine tools that can monitor their own wear and alert you when they need maintenance. This is the future of carbide tools, with embedded sensors and IoT connectivity.

The automotive industry is just one example of how carbide tools are staying ahead of the curve.

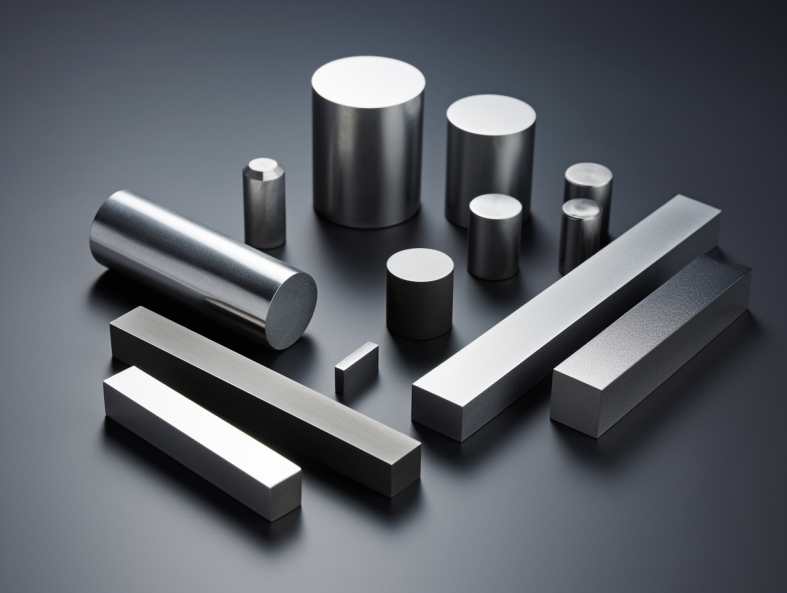

Specific Metal Powder Models for Carbide Tools

When it comes to carbide tools, the metal powders used in their production are crucial. Here are 10 specific models, each with its unique properties:

- Tungsten Carbide (WC): The most common, known for its hardness and wear resistance.

- Titanium Carbide (TiC): Offers excellent heat resistance, ideal for high-speed machining.

- Tantalum Carbide (TaC): Adds toughness and is often used in combination with WC.

- Niobium Carbide (NbC): Improves hardness and is used in cutting tools for stainless steel.

- Vanadium Carbide (VC): Enhances wear resistance and is often used in coatings.

- Chromium Carbide (Cr3C2): Known for its corrosion resistance, perfect for harsh environments.

- Molybdenum Carbide (Mo2C): Adds strength and is used in high-stress applications.

- Hafnium Carbide (HfC): Extremely heat-resistant, used in aerospace applications.

- Zirconium Carbide (ZrC): Offers a balance of hardness and toughness.

- Silicon Carbide (SiC): Used in composite materials for added durability.

Each of these powders brings something unique to the table, allowing manufacturers to tailor their carbide tools to specific needs.

FAQ

| Question | Answer |

|---|---|

| What are carbide tools made of? | A combination of tungsten carbide and cobalt, often with other additives. |

| Are carbide tools better than steel tools? | Yes, they are harder, more durable, and maintain their edge longer. |

| Can carbide tools be sharpened? | Yes, but it requires specialized equipment and expertise. |

| How do I choose the right carbide tool? | Consider the material you’re machining, the type of cut, and tool geometry. |

| Are carbide tools expensive? | They have a higher upfront cost but save money in the long run. |