Unlocking Efficiency: Two Flute End Mills for Superior Material Removal and Surface Finish

Two flute end mills are essential tools in the world of machining, prized for their ability to rapidly remove material and produce a smooth surface finish. These versatile cutting tools come in various configurations, each tailored to specific machining tasks. This comprehensive guide focuses on two prominent types of two flute end mills: straight shank square end mills and straight shank ball end mills. We will delve into their unique characteristics, applications, advantages, and how to choose the right tool for your machining needs.

Understanding the Power of Two: Why Two Flute End Mills?

Two flute end mills are characterized by their two cutting edges, a design that offers distinct advantages:

- Efficient Chip Evacuation: The wider flute spaces between the cutting edges facilitate efficient chip removal, particularly crucial when working with softer materials like aluminum or plastics that tend to produce long, stringy chips. This efficient chip flow prevents chip recutting, improves surface finish, and extends tool life.

- Increased Cutting Speed and Feed Rates: The reduced cutting edge contact allows for higher cutting speeds and feed rates compared to end mills with more flutes. This translates to faster machining times and increased productivity.

- Lower Cutting Forces: With fewer cutting edges engaged in the material, two flute end mills generate lower cutting forces, making them suitable for machining thinner or more delicate workpieces where excessive force could lead to distortion or breakage.

Two Types, Distinct Applications: Square vs. Ball End Mills

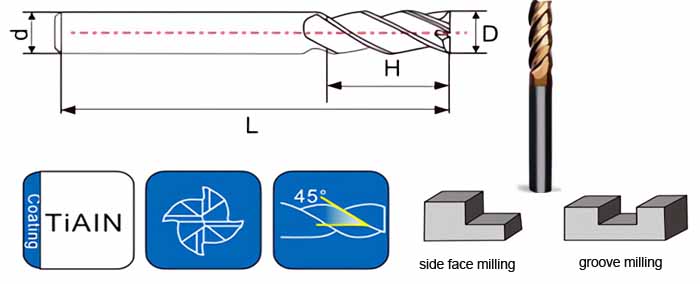

Straight Shank Square End Mills: Masters of Flat Surfaces and Sharp Corners

- Defining Feature: Characterized by a flat bottom with two sharp cutting edges, ideal for creating flat surfaces, shoulders, slots, and pockets with sharp corners.

- Applications: Widely used in milling operations that require precise 90-degree angles, such as:

- Creating Keyways: Machining slots into a shaft or hub to accept a key, which prevents rotation between the two components.

- Machining Steps: Creating stepped features on a workpiece, often used to create different levels or platforms.

- Profiling Edges: Cutting straight edges and profiles on the outside of a workpiece with sharp corners.

- Face Milling: Creating a flat surface by milling across the top of a workpiece.

- Plunge Milling: Cutting straight down into a workpiece to create a deep slot or pocket.

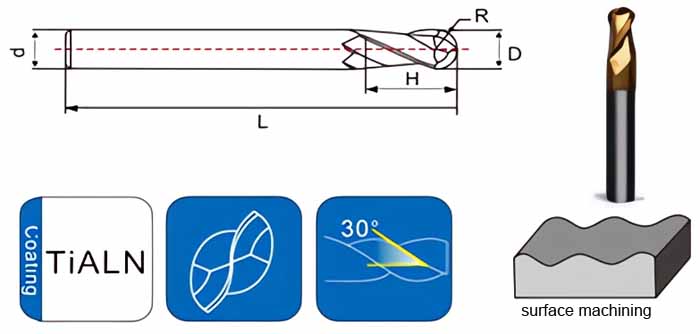

Straight Shank Ball End Mills: Sculpting Contours and Smooth Transitions

- Defining Feature: Distinguished by their hemispherical cutting tip, enabling the creation of contoured surfaces, fillets, radii, and smooth transitions between different features.

- Applications: Excel in applications requiring smooth, flowing surfaces, such as:

- Mold Making: Creating intricate cavities, details, and smooth surfaces in molds used for injection molding, blow molding, and other molding processes.

- Die Sinking: Machining cavities and details into dies used for stamping, forming, and other metal shaping operations.

- Contour Milling: Machining complex 3D shapes and contours by following a predefined path.

- Creating Fillets and Radii: Machining rounded corners and edges to reduce stress concentrations and improve the strength of a part.

- Finishing Complex Surfaces: Creating a smooth, aesthetically pleasing finish on curved or contoured surfaces.

Dissecting the Design: Anatomy of a Two Flute End Mill

Key Components and Their Functions:

- Cutting Edges: Two precisely ground edges responsible for material removal, located on the periphery of the end mill. Their geometry and sharpness directly impact cutting performance and surface finish.

- Flutes: The helical grooves running along the body of the end mill, providing pathways for chip evacuation during machining. Two flute end mills have wider flute spaces, enhancing chip flow.

- Shank: The cylindrical portion of the end mill that is securely held within the tool holder of the milling machine. Straight shanks are common for manual milling machines and some CNC machines.

- Body: The main section of the end mill, typically made from solid carbide for its hardness, wear resistance, and ability to maintain sharp cutting edges.

- Overall Length (OAL): The total length of the end mill, from the tip of the cutting edge to the end of the shank.

- Cutting Diameter: The diameter of the cutting portion of the end mill, determining the width of cut.

From Raw Material to Precision Tool: The Manufacturing Process

A Journey of Transformation:

- Carbide Blank Preparation: The process begins with a cylindrical carbide blank, typically produced through powder metallurgy. The blank’s dimensions are slightly larger than the final end mill dimensions.

- Grinding Operations: Precision grinding machines, often utilizing diamond grinding wheels, are used to shape the carbide blank into the desired end mill geometry. This includes creating the cutting edges, flutes, shank, and overall dimensions.

- Coating Application: To enhance tool life, hardness, and performance, various coatings, such as TiN, TiCN, or AlTiN, can be applied to the end mill using techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD).

- Quality Control and Inspection: Rigorous quality control measures are employed throughout the manufacturing process to ensure the end mills meet stringent dimensional tolerances, surface finish requirements, and performance standards.

Two Flute End Mills in Action: A World of Applications

From Aerospace to Automotive, and Beyond:

- Mold Making: Creating intricate cavities, details, and smooth surfaces in molds used for injection molding, blow molding, and other molding processes. Ball end mills excel in creating contoured mold features.

- Aerospace: Machining lightweight, high-strength alloys like aluminum and titanium for aerospace components, often requiring the precision and smooth finishes offered by ball end mills.

- Automotive: Producing engine components, transmission parts, and other automotive parts that require precise tolerances and smooth finishes, often utilizing both square and ball end mills.

- Medical Device Manufacturing: Creating intricate medical implants, surgical instruments, and devices that demand high precision, smooth surfaces, and biocompatibility. Ball end mills are often preferred for their ability to create complex geometries.

- General Machining and Prototyping: Used across various industries for creating prototypes, fixtures, jigs, and other machined components, with both square and ball end mills finding applications based on the desired geometry.

TRUER: Your Trusted Partner for Premium Two Flute End Mills

Unwavering Commitment to Quality and Performance:

- Precision Engineering: TRUER’s two flute end mills are meticulously engineered to deliver exceptional accuracy, repeatability, and long tool life, ensuring precise cuts and consistent performance.

- Premium Carbide Grades: We source only the highest quality carbide materials, carefully selected for their hardness, toughness, and wear resistance, guaranteeing extended tool life and optimal performance.

- Application-Specific Expertise: Our team of experienced engineers provides expert guidance to help you navigate the selection process and pinpoint the ideal two flute end mill for your specific machining requirements.

- Customization Capabilities: TRUER specializes in crafting custom-engineered solutions to meet even the most demanding and specialized application needs. This includes tailoring geometries, coatings, and sizes to your exact specifications.

TRUER vs. the Competition: A Comparative Analysis of Two Flute End Mill Suppliers

Choosing the Right Partner for Your Machining Needs:

| Supplier | Location | Price Range (per piece, approximate) | Specialties |

|---|---|---|---|

| TRUER | China | $15 – $150+ | Uncompromising quality, application-specific designs, competitive pricing, exceptional customer support |

| Niagara Cutter | USA | $18 – $180+ | Extensive selection of high-performance end mills, known for innovation and quality |

| Ingersoll Cutting Tools | USA | $16 – $160+ | Wide range of cutting tools, including end mills, drills, and reamers, focus on productivity and reliability |

| Kennametal | USA | $20 – $200+ | Global leader in metalworking solutions, offering a comprehensive range of cutting tools and tooling systems |

Note: Prices for two flute end mills are influenced by a multitude of factors, including end mill size, type, material, coating, quantity ordered, and more. Requesting quotes from multiple suppliers is always recommended for comparison.Want to buy a great quality two flute end mills at the right price? Click here..

Weighing the Pros and Cons: Advantages and Limitations of Two Flute End Mills

Making Informed Machining Decisions: A Balanced Perspective

| Feature | Advantages | Limitations |

|---|---|---|

| Efficient Chip Evacuation | – Wider flute spaces facilitate excellent chip removal, especially in softer materials<br> – Reduced chip recutting, leading to improved surface finish and extended tool life | – Not as effective in harder materials that produce smaller chips, where chip packing can become an issue |

| Increased Cutting Speed and Feed Rates | – Fewer cutting edges allow for higher cutting speeds and feed rates, increasing productivity<br> – Reduced cutting time can translate to lower overall machining costs | – Can lead to a rougher surface finish compared to end mills with more flutes, especially in harder materials |

| Lower Cutting Forces | – Suitable for machining thinner or more delicate workpieces where excessive force could cause distortion or breakage<br> – Can reduce tool deflection, improving accuracy | – Not as robust as end mills with more flutes, making them less suitable for heavy-duty roughing operations |

Delving Deeper: Interesting Insights into Two Flute End Mills

Beyond the Basics:

- Center Cutting vs. Non-Center Cutting: Two flute end mills can be center cutting or non-center cutting. Center cutting end mills have cutting edges that extend to the center of the tool, allowing them to plunge directly into a workpiece. Non-center cutting end mills require a pre-drilled hole or a ramping technique to initiate the cut.

- Helix Angle: The helix angle of the flutes influences chip evacuation and cutting action. A higher helix angle promotes aggressive chip removal, while a lower helix angle provides a smoother cut but with less efficient chip evacuation.

- Runout and Balance: End mill runout and balance are crucial for accuracy, surface finish, and tool life. Runout refers to any eccentricity or wobble in the tool’s rotation, while imbalance can cause vibration and premature wear. High-quality end mills are manufactured to minimize runout and ensure proper balance.

Frequently Asked Questions: Addressing Your Two Flute End Mill Queries

1. What are the primary advantages of using a two flute end mill compared to an end mill with more flutes?

Two flute end mills excel in efficient chip evacuation, particularly in softer materials, and allow for higher cutting speeds and feed rates due to reduced cutting edge contact. This translates to faster machining times and increased productivity.

2. When would I choose a straight shank square end mill over a straight shank ball end mill?

Choose a straight shank square end mill when you need to create flat surfaces, shoulders, slots, or pockets with sharp, 90-degree corners. Opt for a ball end mill when smooth, contoured surfaces, fillets, radii, or smooth transitions between features are required.

3. Can I use a two flute end mill for roughing operations?

While two flute end mills can be used for light roughing, especially in softer materials, they are generally better suited for finishing operations or lighter cuts. For heavy-duty roughing, end mills with more flutes and a more robust design are recommended.

4. What are some common signs of wear on a two flute end mill, and how can I extend tool life?

Common wear signs include increased cutting forces, poor surface finish, excessive heat generation, and chipping or breakage of the cutting edges. To extend tool life, use appropriate cutting parameters, apply coolant effectively, maintain a rigid setup, and avoid excessive tool deflection.

5. What is the significance of the coating on a two flute end mill?

Coatings enhance tool life, hardness, and performance. TiN is a versatile general-purpose coating, TiCN offers increased hardness and wear resistance, and AlTiN excels in high-heat applications. Choose a coating based on the material being machined and the desired tool life.