Overview: Engineered for Your Exact Needs

In a world demanding precision and durability, customized carbide button solutions emerge as the answer to industry-specific challenges. These aren’t your off-the-shelf components; they are meticulously engineered masterpieces, tailored to withstand the unique wear and tear encountered in your specific application. From the harshest mining environments to the precision demands of manufacturing, customized carbide buttons deliver unparalleled performance and longevity.

This guide explores the world of customized carbide button solutions, delving into their creation process, the benefits they offer, and how partnering with the right supplier can revolutionize your approach to wear resistance and optimize your operations.

What are Customized Carbide Button Solutions?

Beyond Standard: Tailoring Performance to Your Application

Customized carbide button solutions represent a departure from the limitations of standard, off-the-shelf components. They are meticulously designed and engineered to meet the unique demands of your specific application, encompassing:

- Material Selection: Choosing the optimal carbide grade, cobalt binder content, and any additional alloying elements to achieve the desired hardness, toughness, and wear resistance for your specific operating conditions.

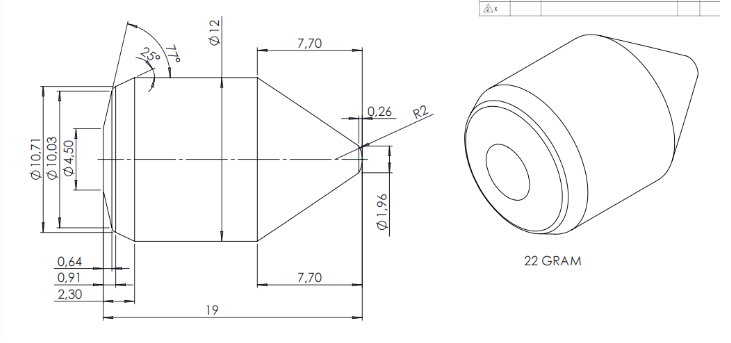

- Shape Optimization: Designing the ideal button shape, considering factors like contact area, wear pattern distribution, and stress points, to maximize performance and longevity in your application.

- Dimensional Precision: Manufacturing to your exact dimensional specifications, ensuring a precise fit within your equipment and optimizing performance, whether it’s a unique diameter, a specific thread pitch, or a complex geometry.

- Attachment Method: Incorporating the ideal attachment method, whether it’s brazing, welding, threading, or a custom solution, to ensure secure and reliable integration into your tools or equipment.

The Customization Process: From Concept to Reality

Collaborating for Success: Bringing Your Vision to Life

Developing customized carbide button solutions is a collaborative journey between you and your chosen supplier, involving:

- Needs Assessment: A thorough understanding of your application, operating conditions, wear challenges, and performance goals forms the foundation for the customization process.

- Design & Engineering: Experienced engineers translate your requirements into a customized button design, utilizing advanced software and simulation tools to optimize shape, material selection, and performance characteristics.

- Prototyping & Testing: Prototypes are often created and rigorously tested under simulated or real-world conditions to validate the design, ensure it meets your performance expectations, and allow for any necessary refinements.

- Production & Quality Control: Upon design approval, the customized buttons are manufactured using precision machining techniques and subjected to stringent quality control measures throughout the production process, guaranteeing consistent quality and performance.

Advantages of Customized Carbide Button Solutions: A Cut Above the Rest

Unlocking Unmatched Performance: The Benefits of Tailored Solutions

- Extended Tool & Equipment Life: Customized buttons, engineered for your specific wear conditions, significantly extend the lifespan of your tools and equipment, reducing downtime and maintenance costs.

- Enhanced Productivity: Optimized button design and material selection lead to improved cutting, crushing, or grinding efficiency, boosting productivity and maximizing output.

- Reduced Downtime: Longer-lasting buttons translate to fewer replacements and less frequent maintenance, minimizing costly downtime and keeping your operations running smoothly.

- Cost Savings: While customized solutions may have a higher upfront cost, the long-term benefits of extended tool life, increased productivity, and reduced downtime often result in significant cost savings over time.

- Competitive Advantage: Gaining an edge in your industry by addressing specific wear challenges and achieving superior performance with tailored carbide button solutions.

Applications Across Industries: Where Customization Makes the Difference

Tailored Solutions for Diverse Challenges: A Glimpse into Industry Applications

- Mining: Customized buttons for drill bits, downhole tools, and crushing equipment withstand the harshest abrasive forces, maximizing drilling efficiency and extending equipment life in demanding underground and surface mining operations.

- Construction & Infrastructure: Tailored solutions for road milling machines, tunnel boring machines, and other heavy equipment ensure optimal performance and longevity in demanding construction projects, from road resurfacing to tunnel excavation.

- Oil & Gas: Customized buttons for drilling bits, stabilizers, and other downhole tools withstand extreme temperatures, pressures, and abrasive formations, maximizing drilling efficiency and reducing downtime in challenging oil and gas exploration and production environments.

- Agriculture: Specialized buttons for tillage tools, seed drills, and harvesting equipment enhance wear resistance and performance in abrasive soils, improving efficiency and reducing maintenance needs in demanding agricultural applications.

- Manufacturing: Custom-designed buttons for dies, punches, cutting tools, and wear parts optimize performance and extend tool life in various manufacturing processes, from metal forming to plastics processing.

Comparing Suppliers: Making Informed Decisions for Customized Solutions

Finding the Right Partner: Navigating the Landscape of Expertise and Value

| Supplier | Location | Price Range (per piece) | Specialties |

|---|---|---|---|

| TRUER | China | $3.00 – $50+ | Extensive customization options, competitive pricing, rapid prototyping, strong customer focus |

| Sandvik Coromant | Global | $5.00 – $75+ | Industry leader, wide range of standard and customized solutions, global presence, strong technical expertise |

| Kennametal | Global | $4.00 – $60+ | Established supplier, broad product portfolio, focus on innovation and application support, global reach |

Note: Prices are approximate and highly dependent on customization factors. Contacting suppliers directly for detailed quotes is recommended.

Advantages and Limitations of Customization: A Balanced Perspective

Weighing the Pros and Cons: Making Informed Decisions for Your Application

| Advantages | Limitations |

|---|---|

| Optimal Performance: Tailored to your specific needs, maximizing efficiency and longevity in your application. | Higher Upfront Cost: Customization often involves higher initial costs compared to standard solutions. |

| Extended Tool Life: Engineered to withstand your unique wear challenges, significantly reducing replacement frequency. | Longer Lead Times: Designing, prototyping, and manufacturing customized solutions typically require longer lead times. |

| Increased Productivity: Optimized design and material selection enhance cutting, crushing, or grinding efficiency. | Minimum Order Quantities: Suppliers often have minimum order quantities for customized solutions, which might not be suitable for small-volume needs. |

| Reduced Downtime: Longer-lasting buttons minimize downtime associated with tool changes and maintenance. | Design Complexity: Highly complex designs might pose manufacturing challenges or limitations, requiring design adjustments or compromises. |

Beyond the Buttons: The Future of Wear Resistance

Innovation and Advancements: Pushing the Boundaries of Performance

The field of customized carbide button solutions is constantly evolving, driven by:

- Advanced Materials: Research into new carbide grades, binder technologies, and surface treatments continuously pushes the boundaries of wear resistance, hardness, and toughness.

- Additive Manufacturing: 3D printing technologies are opening up new possibilities for creating complex carbide button geometries and internal structures, enabling further performance optimization.

- Data-Driven Design: The use of simulation software, data analytics, and machine learning is enabling more precise wear prediction, leading to even more effective customized button designs.

Why Choose TRUER for Your Customized Carbide Button Needs?

TRUER stands out as a premier provider of customized carbide button solutions, offering:

- Unwavering Commitment to Customization: We thrive on tackling unique challenges and providing tailored solutions that precisely meet your specific needs.

- Collaborative Approach: We view our clients as partners, working closely throughout the design, prototyping, and production processes to ensure your complete satisfaction.

- Rapid Prototyping Capabilities: Our efficient prototyping process allows us to quickly iterate designs and validate performance, accelerating your time to market.

- Competitive Pricing and Flexible Solutions: We offer competitive pricing and strive to accommodate various order volumes, making customization accessible for a wide range of businesses.

- Exceptional Customer Service: We prioritize building lasting relationships with our clients, providing responsive communication, technical expertise, and ongoing support.

Frequently Asked Questions: Addressing Your Customization Queries

- Q1: What information do I need to provide to get started with a customized carbide button solution?

- A1: To initiate the process, we need a clear understanding of your application, operating conditions (e.g., materials being processed, temperatures, pressures), wear challenges, desired button lifespan, and any existing button specifications you might have.

- Q2: How long does it typically take to develop and receive a customized carbide button solution?

- A2: The timeline varies depending on the complexity of the design and the need for prototyping and testing. Generally, the process takes 4-8 weeks. We provide transparent lead time estimates upfront and maintain open communication throughout the process.

- Q3: Are there any limitations to the shapes and sizes of customized carbide buttons you can produce?

- A3: While we have extensive capabilities, highly complex geometries or extremely small sizes might present manufacturing challenges. Our engineers will work closely with you to explore design possibilities and find the optimal solution within any potential limitations.

- Q4: What is the typical price range for customized carbide buttons, and what factors influence the cost?

- A4: Prices vary significantly based on factors like carbide grade, button size and complexity, quantity ordered, and any specialized tooling required. We provide detailed quotes outlining all costs involved.