Introduction

Definition of Tungsten Carbide Rod

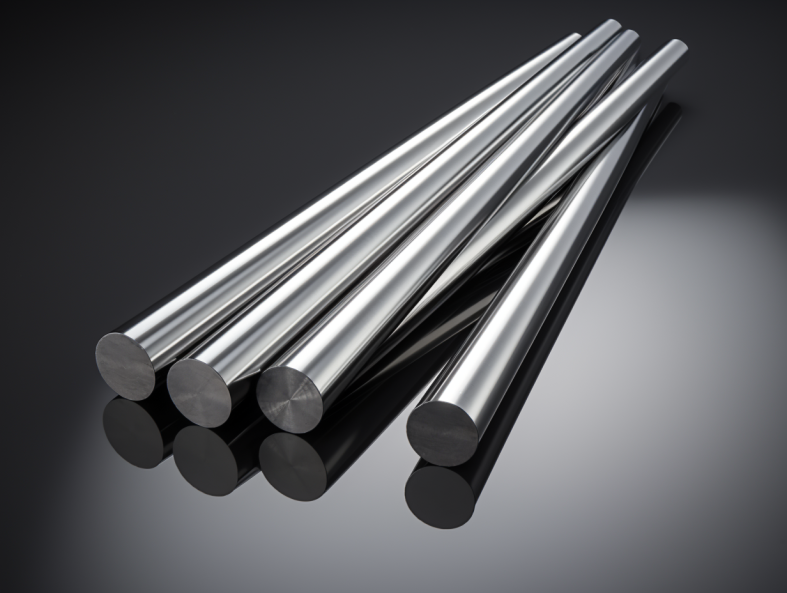

Tungsten carbide rod is a type of hard and durable material that is widely used in various industries. It is made by combining tungsten and carbon atoms through a process called sintering. The resulting rod has excellent strength, wear resistance, and high temperature resistance, making it ideal for applications that require cutting, drilling, or grinding. Tungsten carbide rod is commonly used in the manufacturing of cutting tools, such as drills, end mills, and reamers, as well as in the production of wear parts, such as nozzles, valves, and dies. Its unique properties and versatility make it a valuable material in the field of engineering and manufacturing.

Properties of Tungsten Carbide Rod

Tungsten carbide rod possesses exceptional properties that make it highly desirable in various industries. One of its key characteristics is its exceptional hardness, which is second only to diamond. This makes tungsten carbide rod extremely resistant to wear and abrasion, ensuring its longevity and durability. Additionally, tungsten carbide rod has excellent thermal conductivity, allowing it to efficiently dissipate heat. This property is particularly important in applications where high temperatures are involved. Furthermore, tungsten carbide rod exhibits remarkable strength and toughness, enabling it to withstand heavy loads and impacts without deformation or breakage. These properties make tungsten carbide rod an ideal choice for applications such as cutting tools, drilling equipment, and wear-resistant parts. Overall, the exceptional properties of tungsten carbide rod make it a versatile and reliable material for a wide range of industrial applications.

Applications of Tungsten Carbide Rod

Tungsten carbide rods have a wide range of applications across various industries. One of the key applications of tungsten carbide rods is in the manufacturing of cutting tools and inserts. Due to their exceptional hardness and wear resistance, tungsten carbide rods are ideal for cutting, shaping, and machining tough materials such as steel, cast iron, and aluminum. Additionally, tungsten carbide rods are also used in the production of wear parts, such as nozzles, seals, and bearings, where high strength and durability are required. Moreover, tungsten carbide rods find applications in the mining and construction industry, where they are used for drilling and rock-breaking operations. Overall, the versatility and performance of tungsten carbide rods make them indispensable in various industrial applications.

Manufacturing Process

Raw Materials

Tungsten carbide rods are manufactured using a combination of tungsten and carbon. Tungsten is a hard and dense metal known for its high melting point and excellent strength. Carbon, on the other hand, is a non-metallic element that adds toughness and wear resistance to the material. The combination of tungsten and carbon results in a highly durable and sturdy rod that is widely used in various industries such as manufacturing, construction, and mining. These rods are known for their exceptional hardness, heat resistance, and ability to withstand extreme conditions. The raw materials used in the production of tungsten carbide rods ensure the high quality and reliability of the final product.

Mixing and Grinding

Mixing and grinding are crucial steps in the production of tungsten carbide rods. During the mixing process, various raw materials, including tungsten powder and carbon black, are combined to form a homogeneous mixture. This mixture is then subjected to grinding, which involves reducing the particle size and ensuring uniform distribution of the components. The grinding process helps to enhance the quality and performance of the tungsten carbide rods by improving their density and hardness. Overall, the mixing and grinding steps play a vital role in achieving the desired properties and characteristics of tungsten carbide rods.

Compacting and Shaping

Compacting and shaping are crucial processes in the production of tungsten carbide rods. During the compacting stage, the tungsten carbide powder is subjected to high pressure to form a dense and uniform structure. This helps to enhance the strength and hardness of the rods. Once compacted, the rods undergo shaping, where they are machined and formed into the desired dimensions and specifications. This process ensures that the tungsten carbide rods meet the required tolerances and quality standards. Overall, the compacting and shaping processes play a vital role in producing high-quality tungsten carbide rods that exhibit superior performance and durability.

Properties

Hardness

Tungsten carbide rods are known for their exceptional hardness. With a hardness level that surpasses that of most metals, tungsten carbide rods are widely used in various industries. The high hardness of these rods makes them ideal for applications that require resistance to wear, abrasion, and deformation. Additionally, their hardness enables them to withstand high temperatures and maintain their structural integrity. Due to their remarkable hardness, tungsten carbide rods are commonly used in cutting tools, drilling equipment, and wear-resistant parts. The hardness of tungsten carbide rods ensures that they can withstand the toughest conditions and provide long-lasting performance.

Strength

Tungsten carbide rod is known for its exceptional strength, making it a popular choice in various industries. With a high hardness rating and excellent resistance to wear and abrasion, this material is capable of withstanding extreme conditions and heavy-duty applications. The superior strength of tungsten carbide rod allows it to maintain its shape and integrity even under intense pressure and impact, ensuring long-lasting performance and reliability. Whether used in manufacturing tools, cutting equipment, or industrial machinery, the strength of tungsten carbide rod provides the durability and stability required for efficient and precise operations.

Wear Resistance

Tungsten carbide rods are renowned for their exceptional wear resistance. This unique property is attributed to the combination of tungsten and carbon, which forms an incredibly hard and durable material. The high hardness of tungsten carbide rods allows them to withstand extreme conditions and resist wear and tear, making them ideal for applications that require long-lasting performance. Whether it is in the manufacturing industry, mining, or construction, tungsten carbide rods are widely used to enhance the wear resistance of various tools and components. With their remarkable ability to withstand abrasion and maintain their shape, tungsten carbide rods are a reliable choice for industries that demand superior durability and performance.

Applications

Metalworking

Metalworking is a broad field that involves the shaping, cutting, and joining of metals to create various products. One important material used in metalworking is tungsten carbide rod. Tungsten carbide rod is a durable and high-performance material that is commonly used in the manufacturing of cutting tools, such as drills, milling cutters, and reamers. Its exceptional hardness and wear resistance make it ideal for applications that require precision and long-lasting performance. With its ability to withstand high temperatures and maintain its strength, tungsten carbide rod is also used in the production of parts for the aerospace and automotive industries. Overall, tungsten carbide rod plays a crucial role in metalworking, enabling the production of high-quality and reliable metal products.

Woodworking

Woodworking is a versatile craft that involves shaping and creating objects out of wood. From intricate furniture pieces to simple home decor items, woodworking offers endless possibilities for creativity and craftsmanship. When it comes to working with wood, having the right tools is essential, and one such tool that has gained popularity in recent years is the tungsten carbide rod. This durable and high-performance tool is specifically designed for woodworking, offering exceptional strength and precision. With a tungsten carbide rod, woodworkers can effortlessly carve, shape, and smooth wood, making it an indispensable tool in the woodworking industry.

Mining

Mining plays a crucial role in the production of tungsten carbide rods. Tungsten, one of the main components of tungsten carbide, is primarily obtained through mining. The process involves extracting tungsten ore from underground mines and then refining it to obtain pure tungsten. This raw material is then combined with carbon to create tungsten carbide, a highly durable and versatile material used in various industries. The mining of tungsten not only ensures the availability of this important resource but also supports economic growth and development in mining regions.

Advantages

High Hardness

Tungsten carbide rod is known for its exceptional hardness, making it a popular choice in various industries. With a hardness level that surpasses that of steel, tungsten carbide rod is highly resistant to wear and abrasion. This makes it ideal for applications that require durability and longevity, such as in the manufacturing of cutting tools, dies, and molds. Its high hardness also allows for excellent performance in high-temperature environments, where other materials may fail. Overall, the high hardness of tungsten carbide rod ensures superior performance and reliability in demanding industrial applications.

Excellent Wear Resistance

Tungsten carbide rod is widely known for its excellent wear resistance. It is a versatile material that is commonly used in various industries, including manufacturing, mining, and construction. The unique combination of tungsten and carbon gives the rod its exceptional hardness and durability, making it highly resistant to abrasion and wear. This makes it an ideal choice for applications that involve high levels of friction and impact, such as cutting tools, drill bits, and wear parts. With its outstanding wear resistance properties, tungsten carbide rod offers extended tool life and improved performance, making it a preferred material in demanding environments where durability and reliability are crucial.

Good Thermal Conductivity

Tungsten carbide rod exhibits excellent thermal conductivity, making it a highly sought-after material in various industries. With its ability to efficiently transfer heat, it is widely used in applications where heat dissipation is crucial. The high thermal conductivity of tungsten carbide rod ensures that heat is effectively distributed and dissipated, preventing overheating and ensuring optimal performance. This property makes it an ideal choice for industries such as electronics, automotive, and aerospace, where thermal management is of utmost importance. Additionally, the good thermal conductivity of tungsten carbide rod allows for faster heat transfer, reducing the risk of thermal damage and improving overall efficiency.

Conclusion

Summary of Tungsten Carbide Rod

Tungsten carbide rod is a versatile and durable material that is widely used in various industries. It is a type of hard metal that is composed of tungsten and carbon atoms. The unique combination of these elements gives tungsten carbide rod its exceptional hardness, strength, and wear resistance. This makes it ideal for applications that require high-performance and long-lasting materials, such as cutting tools, drills, milling machines, and industrial machinery. Additionally, tungsten carbide rod has excellent thermal and electrical conductivity, making it suitable for use in electronic components and heat-resistant applications. Overall, the summary of tungsten carbide rod highlights its outstanding properties and its significant role in enhancing the performance and efficiency of various industrial processes.

Future Developments

Future Developments:

In the future, there are several exciting developments expected in the field of tungsten carbide rods. One of the key areas of focus is improving the durability and performance of these rods. Researchers are exploring new manufacturing techniques and materials that can enhance the strength and wear resistance of tungsten carbide rods. Additionally, there is a growing interest in developing sustainable and eco-friendly alternatives to traditional tungsten carbide rods. This includes investigating new materials that can provide similar properties while reducing the environmental impact. The future of tungsten carbide rods looks promising, with advancements in technology and research paving the way for even better performance and sustainability.

Final Thoughts

In conclusion, tungsten carbide rods are an essential component in various industries due to their exceptional strength, durability, and resistance to wear and tear. Whether used in the manufacturing of cutting tools, molds, or even jewelry, these rods offer unparalleled performance and reliability. With their ability to withstand high temperatures and maintain their shape under extreme pressure, tungsten carbide rods have proven to be a valuable asset in numerous applications. As technology continues to advance, the demand for tungsten carbide rods is expected to grow, making them a vital material in the future of industrial development.