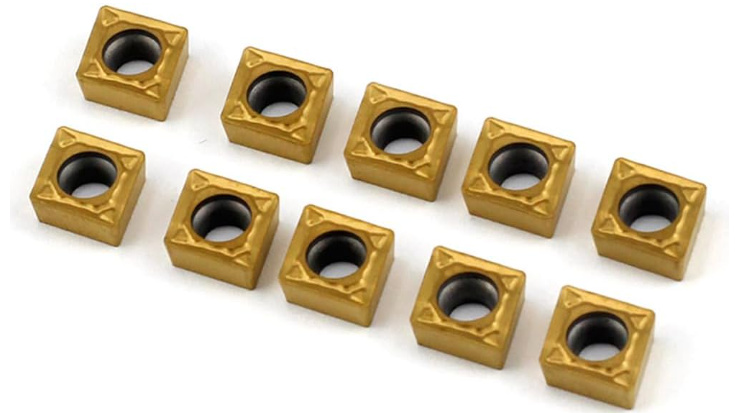

In the world of machining, where precision and efficiency reign supreme, choosing the right cutting tool material can make all the difference. While various options exist, carbide inserts have emerged as the undisputed champions, revolutionizing machining processes across countless industries.

But what exactly makes carbide inserts superior to other cutting tool materials? This blog post delves into the 7 compelling advantages that have propelled carbide inserts to the forefront of modern manufacturing.

1. Unmatched Hardness: Conquering the Toughest Materials

Carbide inserts, primarily composed of tungsten carbide, boast exceptional hardness, significantly surpassing that of traditional tool steels and high-speed steel (HSS) counterparts. This remarkable hardness allows carbide inserts to effortlessly machine a wide range of materials, including:

- Hardened Steels: Carbide inserts can tackle hardened steels that would quickly dull or damage HSS tools, expanding machining possibilities and enabling the creation of more durable components.

- Exotic Alloys: Aerospace and other high-performance industries rely on exotic alloys with exceptional strength-to-weight ratios. Carbide inserts excel at machining these challenging materials, contributing to advancements in aerospace, medical, and other demanding fields.

- Abrasive Materials: Materials like cast iron, fiberglass, and carbon fiber composites, known for their abrasive properties, can quickly wear down traditional cutting tools. Carbide inserts, with their superior hardness, resist wear and maintain their cutting edge for extended periods, even when machining these abrasive materials.

2. Exceptional Wear Resistance: Minimizing Downtime, Maximizing Productivity

One of the most significant advantages of carbide inserts lies in their exceptional wear resistance. Compared to other cutting tool materials, carbide inserts maintain their sharp cutting edges for significantly longer periods. This translates into:

- Reduced Tool Changes: Fewer tool changes mean less downtime and increased machine utilization, directly impacting productivity and profitability.

- Lower Tooling Costs: While carbide inserts may have a higher initial cost, their extended lifespan often results in lower overall tooling expenses over time.

- Improved Part Consistency: Consistent tool wear ensures greater dimensional accuracy and surface finish consistency throughout production runs, reducing scrap rates and improving overall part quality.

3. High-Speed Machining: Accelerating Production, Boosting Efficiency

Carbide inserts are engineered to withstand the extreme temperatures and forces generated during high-speed machining operations. This allows for:

- Increased Cutting Speeds: Carbide inserts can operate at significantly higher cutting speeds than HSS tools, dramatically reducing machining times and boosting production output.

- Improved Surface Finishes: Higher cutting speeds, when combined with the inherent properties of carbide inserts, often result in smoother surface finishes, reducing or eliminating the need for secondary finishing operations.

- Enhanced Chip Control: Carbide inserts, with their sharp cutting edges and optimized geometries, promote efficient chip formation and evacuation, crucial for maintaining consistent cutting performance and preventing chip buildup that can damage the workpiece or tool.

4. Versatility in Application: A Tool for Every Task

Carbide inserts are incredibly versatile, available in a vast array of grades, geometries, and coatings tailored to specific machining operations and materials. This extensive range of options ensures that there’s a carbide insert perfectly suited for virtually any machining task, including:

- Turning: From roughing to finishing operations, carbide inserts excel at turning external and internal diameters, creating grooves, and parting off components.

- Milling: Carbide inserts are widely used in milling applications, efficiently removing material in face milling, shoulder milling, and slot milling operations.

- Drilling: Carbide-tipped drills offer superior performance in drilling applications, particularly when drilling hard materials or requiring high-precision holes.

- Boring: Carbide inserts are also used in boring tools, enabling the creation of precise internal diameters and smooth bore finishes.

5. Enhanced Precision and Accuracy: Meeting Tight Tolerance Demands

Modern manufacturing often demands incredibly tight tolerances, particularly in industries like aerospace, medical, and electronics. Carbide insert, with their ability to maintain sharp cutting edges and resist deflection under high cutting forces, excel at meeting these stringent requirements:

- Intricate Geometries: Carbide insert can produce complex shapes and features with exceptional accuracy, essential for components with intricate designs or tight tolerance requirements.

- Reduced Vibration: The inherent stiffness of carbide insert minimizes vibration during machining, contributing to improved surface finishes and enhanced dimensional accuracy.

- Fine Surface Finishes: Carbide insert can achieve extremely fine surface finishes, often eliminating the need for secondary finishing operations like grinding or polishing.

6. Cost-Effectiveness in the Long Run: Maximizing Return on Investment

While carbide insert may have a higher upfront cost compared to some traditional tool materials, their long-term cost-effectiveness is undeniable.

Consider these factors:

- Extended Tool Life: Carbide insert last significantly longer than HSS tools, reducing the frequency of tool replacements and lowering overall tooling costs.

- Increased Productivity: Higher cutting speeds and reduced downtime for tool changes translate into increased production output, maximizing return on investment.

- Improved Part Quality: Consistent tool wear and enhanced precision result in higher-quality parts, reducing scrap rates and minimizing material waste.

7. Compatibility with Advanced Machining Technologies

Carbide insert are compatible with a wide range of advanced machining technologies, further enhancing their capabilities and expanding their applications:

- CNC Machining: Carbide insert are ideally suited for use in computer numerical control (CNC) machining centers, where precision and repeatability are paramount.

- High-Pressure Coolant Systems: Using high-pressure coolant systems in conjunction with carbide insert optimizes chip evacuation, improves heat dissipation, and extends tool life, particularly in demanding machining operations.

- Dry Machining: Some grades of carbide insert are specifically designed for dry machining applications, eliminating the need for cutting fluids and promoting environmentally friendly manufacturing processes.

Carbide Insert vs. Other Cutting Tool Materials: A Comparative Glance

| Material | Hardness | Wear Resistance | Cutting Speed | Cost | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Carbide Insert | Extremely High | Excellent | High | High | Exceptional hardness, wear resistance, high-speed capability, versatility, precision | Higher initial cost |

| High-Speed Steel (HSS) | High | Good | Moderate | Moderate | Good overall balance of properties, suitable for a wide range of materials | Lower hardness and wear resistance compared to carbide insert |

| Cobalt Steel | Very High | Very Good | Moderate | High | Excellent heat resistance, suitable for high-temperature applications | More expensive than HSS, lower hardness than carbide insert |

| Ceramics | Extremely High | Excellent | Very High | Very High | Exceptional hardness, wear resistance, and high-speed capability, suitable for very hard materials | Brittle, susceptible to chipping or breakage |

Conclusion: Embracing the Carbide Advantage

The advantages of carbide insert over other cutting tool materials are undeniable. Their exceptional hardness, wear resistance, high-speed capability, versatility, and precision have revolutionized machining processes, enabling the creation of higher-quality, more complex, and more affordable products across a multitude of industries.

As technology continues to advance and manufacturing demands become increasingly stringent, carbide insert will undoubtedly remain at the forefront of cutting-tool technology, driving innovation and shaping the future of manufacturing.

Want to buy a great quality carbide insert at the right price? Click here.