- 2 Straight Coolant Holes Carbide Rod

2 Straight Coolant Holes Carbide Rod

The 2-hole design on the carbide rod allows for increased coolant flow and better chip evacuation compared to a single-hole design. This helps to improve tool life and cutting performance, especially in high-speed machining operations where heat and chip buildup can be a problem, widely used in drills, reamers, carbide holders. We supply both unground and ground carbide rods with two cooling holes in varied grades. If you would like to learn more about our carbide grades, please click on the link below to browse the grade page.

A comprehensive standard selection of carbide rods with two straight cooling holes in various dimensions is available in the below tables, but other sizes, tolerances & configurations also available on request.

Contact us if what you need is not shown here.

Introduction

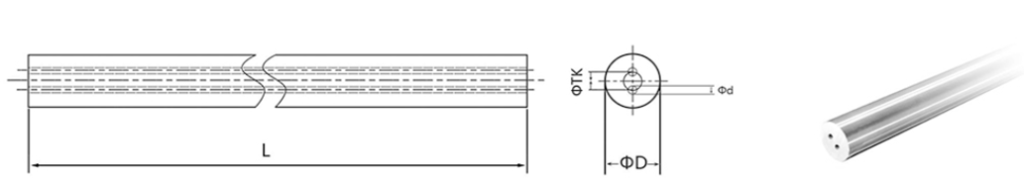

The 2 Straight Coolant Holes Carbide Rod is a cylindrical tool made of solid carbide material with two straight coolant holes running through its center. These coolant holes are precisely aligned and designed to deliver coolant or cutting fluid directly to the cutting edge during machining operations.

What is a 2 Straight Coolant Holes Carbide Rod?

The 2 Straight Coolant Holes Carbide Rod is a specialized tool that combines the advantages of solid carbide material with the benefits of dual coolant holes. It provides enhanced cooling capabilities, improved chip evacuation, and extended tool life, contributing to efficient and reliable machining processes

Composition and Structure

The composition of tungsten carbide particles and a metallic binder, along with the structure of the 2 Straight Coolant Holes Carbide Rod, result in a tool with superior hardness, strength, wear resistance, and efficient coolant delivery capabilities. These properties make it an excellent choice for various machining applications that require reliable and high-performance cutting tools.

Dual Coolant Holes

The rod has two evenly distributed straight coolant holes for targeted cooling and chip evacuation.

Symmetrical Placement

The coolant holes are positioned symmetrically on the rod, ensuring balanced coolant flow and consistent cooling performance.

Adjustable Flow Rate

The flow rate of coolant through each hole can be adjusted to suit application requirements.

Diameter and Depth

The dimensions of the coolant holes are optimized for efficient coolant flow and effective cooling.

Compatibility

The rod is designed to be compatible with tool holders, collets, and cutting tools accommodating this coolant hole configuration.

Enhanced Cooling and Chip Evacuation

The dual coolant holes provide efficient cooling, reducing cutting temperatures, tool wear, and improving chip evacuation.

Machining Flexibility

Two coolant holes offer flexibility in tool design and machining strategies, allowing for various coolant delivery options.

Versatile Applications

The rod is suitable for drilling, milling, and other cutting operations, particularly in demanding machining conditions.

Material Preparation

Tungsten carbide powder and binder material are mixed to create the desired composition.

Powder Compaction

The mixture is compacted under high pressure to form a green compact.

Pre-Sintering

The green compact undergoes a pre-sintering process to remove binders and increase strength.

Machining and Drilling

The pre-sintered rod is machined to the desired shape and then drilled with two straight coolant holes.

Sintering

The rod is sintered at high temperatures to bond the carbide particles together.

Finishing Operations

Additional finishing processes, such as grinding or polishing, may be performed.

Quality Control

Stringent inspections and tests are conducted to ensure the rods meet quality standards.

Milling

The carbide rod is used in milling operations for cutting surfaces, contours, and pockets in different materials. The dual coolant holes ensure effective coolant flow, improving cooling and chip evacuation during milling.

Drilling

The carbide rod is employed in drilling applications to create holes in various materials. The straight coolant holes facilitate efficient coolant delivery, reducing heat and prolonging tool life while enhancing chip evacuation.

Turning

The carbide rod is utilized in turning operations to shape and create cylindrical components. The straight coolant holes allow for efficient coolant flow, reducing heat buildup, and improving chip evacuation.

Reaming

The carbide rod is applied in reaming processes to refine and accurately size existing holes. The straight coolant holes aid in effective coolant delivery, preventing tool overheating, and ensuring precise cutting.

Milling

The carbide rod is used in milling operations for cutting surfaces, contours, and pockets in different materials. The dual coolant holes ensure effective coolant flow, improving cooling and chip evacuation during milling.

Drilling

The carbide rod is employed in drilling applications to create holes in various materials. The straight coolant holes facilitate efficient coolant delivery, reducing heat and prolonging tool life while enhancing chip evacuation.

Turning

The carbide rod is utilized in turning operations to shape and create cylindrical components. The straight coolant holes allow for efficient coolant flow, reducing heat buildup, and improving chip evacuation.

Reaming

The carbide rod is applied in reaming processes to refine and accurately size existing holes. The straight coolant holes aid in effective coolant delivery, preventing tool overheating, and ensuring precise cutting.

A carbide rod with two straight coolant holes is a cutting tool component made from tungsten carbide or a combination of tungsten carbide and cobalt. It features two evenly spaced cylindrical holes that run parallel to the rod’s axis, designed to provide targeted cooling and chip evacuation during machining operations.

The presence of two straight coolant holes offers several advantages. It enhances cooling at the cutting edge, reducing tool wear and increasing tool life. It also improves chip evacuation, maintaining a clear cutting path and enhancing machining efficiency. Additionally, it allows for higher cutting speeds and feeds, resulting in increased productivity.

Carbide rods with two straight coolant holes are used in various machining applications such as drilling, milling, reaming, and other precision cutting operations. They are particularly useful in high-speed and high-temperature machining environments.

Yes, the flow rate of coolant through each hole can be adjusted based on specific application requirements. This flexibility allows for customization and optimization of the cooling and chip evacuation process.

Yes, carbide rods with two straight coolant holes are designed to be compatible with tool holders, collets, and cutting tools specifically designed to accommodate this coolant hole configuration. They can be easily integrated into machining setups.

The manufacturing process typically involves material preparation, powder compaction, pre-sintering, machining and drilling, sintering, finishing operations, and quality control. Specific steps may vary among manufacturers.

Yes, carbide rods with two straight coolant holes can be customized based on specific requirements. The number, size, and positioning of the coolant holes can be tailored to suit the tool’s design and application needs.

It is important to follow the manufacturer’s guidelines and recommendations for optimal performance and safety. Proper coolant selection, flow rate adjustment, and regular maintenance are essential for maximizing the benefits of these rods.

Data

Unground 2 Straight Coolant Holes Carbide Rod Description

The unground 2 Straight Coolant Holes Carbide Rod is a cylindrical tool made of solid carbide material with two straight coolant holes running through its center. Unlike the ground version, the unground rod has not undergone precision grinding to achieve a smooth and precise surface finish. The unground carbide rod is typically in its raw form, with a rough surface. It is designed to be further processed and customized according to specific machining requirements. The coolant holes are present to enable efficient coolant delivery during machining operations, ensuring effective cooling, lubrication, and chip evacuation.

| Part No. | D/mm | L/mm | d/mm | TK/mm | Tol. of D/mm | Tol. of L/mm | Tol. of d/mm | Tol. of TK/mm | Grade (click here) |

|---|---|---|---|---|---|---|---|---|---|

| RHUK04003300-2S0080-0180 | 4.0 | 330 | 0.80 | 1.80 | +0.50/+0.30 | 0, +5 | ±0.10 | +0/-0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-2S0080-0200 | 5.0 | 330 | 0.80 | 2.00 | +0.50/+0.30 | 0, +5 | ±0.10 | +0/-0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-2S0100-0300 | 6.0 | 330 | 1.00 | 3.00 | +0.50/+0.30 | 0, +5 | ±0.15 | +0/-0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-2S0100-0350 | 7.0 | 330 | 1.00 | 3.50 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-2S0100-0400 | 8.0 | 330 | 1.00 | 4.00 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK09003300-2S0140-0400 | 9.0 | 330 | 1.40 | 4.00 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-2S0140-0500 | 10.0 | 330 | 1.40 | 5.00 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK11003300-2S0140-0500 | 11.0 | 330 | 1.40 | 5.00 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-2S0175-0600 | 12.0 | 330 | 1.75 | 6.00 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK13003300-2S0175-0600 | 13.0 | 330 | 1.75 | 6.00 | +0.70/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK14003300-2S0175-0700 | 14.0 | 330 | 1.75 | 7.00 | +0.70/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK15003300-2S0200-0700 | 15.0 | 330 | 2.00 | 7.00 | +0.70/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK16003300-2S0200-0800 | 16.0 | 330 | 2.00 | 8.00 | +0.70/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK17003300-2S0200-0800 | 17.0 | 330 | 2.00 | 8.00 | +0.80/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK18003300-2S0200-0900 | 18.0 | 330 | 2.00 | 9.00 | +0.80/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK19003300-2S0200-0900 | 19.0 | 330 | 2.00 | 9.00 | +0.80/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK20003300-2S0250-1000 | 20.0 | 330 | 2.50 | 10.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK21003300-2S0250-1000 | 21.0 | 330 | 2.50 | 10.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK22003300-2S0250-1100 | 22.0 | 330 | 2.50 | 11.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK23003300-2S0250-1100 | 23.0 | 330 | 2.50 | 11.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK24003300-2S0300-1200 | 24.0 | 330 | 3.00 | 12.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.50 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK25003300-2S0300-1200 | 25.0 | 330 | 3.00 | 12.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.50 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK26003300-2S0300-1300 | 26.0 | 330 | 3.00 | 13.00 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.50 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-2S0080-0150 | 6.0 | 330 | 0.80 | 1.50 | +0.50/+0.30 | 0, +5 | ±0.15 | +0/-0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-2S0080-0150 | 7.0 | 330 | 0.80 | 1.50 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-2S0100-0150 | 8.0 | 330 | 1.00 | 1.50 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK09003300-2S0100-0260 | 9.0 | 330 | 1.00 | 2.60 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-2S0100-0260 | 10.0 | 330 | 1.00 | 2.60 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK11003300-2S0120-0360 | 11.0 | 330 | 1.20 | 3.60 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-2S0120-0360 | 12.0 | 330 | 1.20 | 3.60 | +0.60/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK13003300-2S0120-0360 | 13.0 | 330 | 1.20 | 3.60 | +0.70/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK14003300-2S0150-0500 | 14.0 | 330 | 1.50 | 5.00 | +0.70/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK15003300-2S0150-0500 | 15.0 | 330 | 1.50 | 5.00 | +0.70/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK16003300-2S0150-0500 | 16.0 | 330 | 1.50 | 5.00 | +0.70/+0.30 | 0, +5 | ±0.15 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK17003300-2S0200-0620 | 17.0 | 330 | 2.00 | 6.20 | +0.80/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK18003300-2S0200-0620 | 18.0 | 330 | 2.00 | 6.20 | +0.80/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK19003300-2S0200-0620 | 19.0 | 330 | 2.00 | 6.20 | +0.80/+0.30 | 0, +5 | ±0.20 | +0/-0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK20003300-2S0200-0620 | 20.0 | 330 | 2.00 | 6.20 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK21003300-2S0200-0620 | 21.0 | 330 | 2.00 | 6.20 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK22003300-2S0200-0620 | 22.0 | 330 | 2.00 | 6.20 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK23003300-2S0200-0750 | 23.0 | 330 | 2.00 | 7.50 | +0.80/+0.30 | 0, +5 | ±0.25 | +0/-0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK24003300-2S0200-0750 | 24.0 | 330 | 2.00 | 7.50 | +0.80/+0.30 | 0, +5 | ±0.30 | +0/-0.50 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK25003300-2S0200-0750 | 25.0 | 330 | 2.00 | 7.50 | +0.80/+0.30 | 0, +5 | ±0.30 | +0/-0.50 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK26003300-2S0200-0750 | 26.0 | 330 | 2.00 | 7.50 | +0.80/+0.30 | 0, +5 | ±0.30 | +0/-0.50 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| Part No. | D/mm | L/mm | d/mm | TK/mm | Tol. of D/mm | Tol. of L/mm | Tol. of d/mm | Tol. of TK/mm | Grade (click here) |

|---|---|---|---|---|---|---|---|---|---|

| RHUJ04003300-2S0080-0180 | 4.0 | 330 | 0.80 | 1.80 | +0.30/+0.50 | 0, +5 | ±0.10 | +0/-0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ05003300-2S0080-0200 | 5.0 | 330 | 0.80 | 2.00 | +0.30/+0.50 | 0, +5 | ±0.10 | +0/-0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ06003300-2S0100-0300 | 6.0 | 330 | 1.00 | 3.00 | +0.30/+0.50 | 0, +5 | ±0.15 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ07003300-2S0100-0350 | 7.0 | 330 | 1.00 | 3.50 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ08003300-2S0100-0400 | 8.0 | 330 | 1.00 | 4.00 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ09003300-2S0140-0400 | 9.0 | 330 | 1.40 | 4.00 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ10003300-2S0140-0500 | 10.0 | 330 | 1.40 | 5.00 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ11003300-2S0140-0500 | 11.0 | 330 | 1.40 | 5.00 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ12003300-2S0175-0600 | 12.0 | 330 | 1.75 | 6.00 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ13003300-2S0175-0600 | 13.0 | 330 | 1.75 | 6.00 | +0.30/+0.70 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ14003300-2S0175-0700 | 14.0 | 330 | 1.75 | 7.00 | +0.30/+0.70 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ15003300-2S0200-0700 | 15.0 | 330 | 2.00 | 7.00 | +0.30/+0.70 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ16003300-2S0200-0800 | 16.0 | 330 | 2.00 | 8.00 | +0.30/+0.70 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ17003300-2S0200-0800 | 17.0 | 330 | 2.00 | 8.00 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ18003300-2S0200-0900 | 18.0 | 330 | 2.00 | 9.00 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ19003300-2S0200-0900 | 19.0 | 330 | 2.00 | 9.00 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ20003300-2S0250-1000 | 20.0 | 330 | 2.50 | 10.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ21003300-2S0250-1000 | 21.0 | 330 | 2.50 | 10.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ22003300-2S0250-1100 | 22.0 | 330 | 2.50 | 11.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ23003300-2S0250-1100 | 23.0 | 330 | 2.50 | 11.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ24003300-2S0300-1200 | 24.0 | 330 | 3.00 | 12.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ25003300-2S0300-1200 | 25.0 | 330 | 3.00 | 12.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ26003300-2S0300-1300 | 26.0 | 330 | 3.00 | 13.00 | +0.30/+0.80 | 0, +5 | ±0.25 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ06003300-2S0080-0150 | 6.0 | 330 | 0.80 | 1.50 | +0.30/+0.50 | 0, +5 | ±0.10 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ07003300-2S0080-0150 | 7.0 | 330 | 0.80 | 1.50 | +0.30/+0.60 | 0, +5 | ±0.10 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ08003300-2S0100-0150 | 8.0 | 330 | 1.00 | 1.50 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ09003300-2S0100-0260 | 9.0 | 330 | 1.00 | 2.60 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ10003300-2S0100-0260 | 10.0 | 330 | 1.00 | 2.60 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ11003300-2S0120-0360 | 11.0 | 330 | 1.20 | 3.60 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ12003300-2S0120-0360 | 12.0 | 330 | 1.20 | 3.60 | +0.30/+0.60 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ13003300-2S0120-0360 | 13.0 | 330 | 1.20 | 3.60 | +0.30/+0.70 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ14003300-2S0150-0500 | 14.0 | 330 | 1.50 | 5.00 | +0.30/+0.70 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ15003300-2S0150-0500 | 15.0 | 330 | 1.50 | 5.00 | +0.30/+0.70 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ16003300-2S0150-0500 | 16.0 | 330 | 1.50 | 5.00 | +0.30/+0.70 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ17003300-2S0200-0620 | 17.0 | 330 | 2.00 | 6.20 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ18003300-2S0200-0620 | 18.0 | 330 | 2.00 | 6.20 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ19003300-2S0200-0620 | 19.0 | 330 | 2.00 | 6.20 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ20003300-2S0200-0620 | 20.0 | 330 | 2.00 | 6.20 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ21003300-2S0200-0620 | 21.0 | 330 | 2.00 | 6.20 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ22003300-2S0200-0620 | 22.0 | 330 | 2.00 | 6.20 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ23003300-2S0200-0750 | 23.0 | 330 | 2.00 | 7.50 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ24003300-2S0200-0750 | 24.0 | 330 | 2.00 | 7.50 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ25003300-2S0200-0750 | 25.0 | 330 | 2.00 | 7.50 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ26003300-2S0200-0750 | 26.0 | 330 | 2.00 | 7.50 | +0.30/+0.80 | 0, +5 | ±0.20 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

Ground 2 Straight Coolant Holes Carbide Rod Description

The ground 2 Straight Coolant Holes Carbide Rod is a precision-engineered cylindrical tool made of solid carbide material. It features two straight coolant holes that are precisely aligned and ground to achieve a smooth and accurate surface finish.

This ground carbide rod offers several advantages. The precise grinding process ensures tight tolerances, resulting in accurate dimensions and geometric consistency. The smooth surface finish reduces friction during machining operations, improving chip evacuation and enhancing overall cutting performance.

| Part No. | D/mm | L/mm | d/mm | TK/mm | Tol. of D/mm | Tol. of L/mm | Tol. of d/mm | Tol. of TK/mm | Grade (click here) |

|---|---|---|---|---|---|---|---|---|---|

| RHUJ04003300-2S0080-0180 | 4.0 | 330 | 0.80 | 1.80 | h6 | 0, +5 | ±0.10 | +0/-0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ05003300-2S0080-0200 | 5.0 | 330 | 0.80 | 2.00 | h6 | 0, +5 | ±0.10 | +0/-0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ06003300-2S0100-0300 | 6.0 | 330 | 1.00 | 3.00 | h6 | 0, +5 | ±0.15 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ07003300-2S0100-0350 | 7.0 | 330 | 1.00 | 3.50 | h6 | 0, +5 | ±0.15 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ08003300-2S0100-0400 | 8.0 | 330 | 1.00 | 4.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ09003300-2S0140-0400 | 9.0 | 330 | 1.40 | 4.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ10003300-2S0140-0500 | 10.0 | 330 | 1.40 | 5.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ11003300-2S0140-0500 | 11.0 | 330 | 1.40 | 5.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ12003300-2S0175-0600 | 12.0 | 330 | 1.75 | 6.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ13003300-2S0175-0600 | 13.0 | 330 | 1.75 | 6.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ14003300-2S0175-0700 | 14.0 | 330 | 1.75 | 7.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ15003300-2S0200-0700 | 15.0 | 330 | 2.00 | 7.00 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ16003300-2S0200-0800 | 16.0 | 330 | 2.00 | 8.00 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ17003300-2S0200-0800 | 17.0 | 330 | 2.00 | 8.00 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ18003300-2S0200-0900 | 18.0 | 330 | 2.00 | 9.00 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ19003300-2S0200-0900 | 19.0 | 330 | 2.00 | 9.00 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ20003300-2S0250-1000 | 20.0 | 330 | 2.50 | 10.00 | h6 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ21003300-2S0250-1000 | 21.0 | 330 | 2.50 | 10.00 | h6 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ22003300-2S0250-1100 | 22.0 | 330 | 2.50 | 11.00 | h6 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ23003300-2S0250-1100 | 23.0 | 330 | 2.50 | 11.00 | h6 | 0, +5 | ±0.25 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ24003300-2S0300-1200 | 24.0 | 330 | 3.00 | 12.00 | h6 | 0, +5 | ±0.25 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ25003300-2S0300-1200 | 25.0 | 330 | 3.00 | 12.00 | h6 | 0, +5 | ±0.25 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ26003300-2S0300-1300 | 26.0 | 330 | 3.00 | 13.00 | h6 | 0, +5 | ±0.25 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ06003300-2S0080-0150 | 6.0 | 330 | 0.80 | 1.50 | h6 | 0, +5 | ±0.10 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ07003300-2S0080-0150 | 7.0 | 330 | 0.80 | 1.50 | h6 | 0, +5 | ±0.10 | +0/-0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ08003300-2S0100-0150 | 8.0 | 330 | 1.00 | 1.50 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ09003300-2S0100-0260 | 9.0 | 330 | 1.00 | 2.60 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ10003300-2S0100-0260 | 10.0 | 330 | 1.00 | 2.60 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ11003300-2S0120-0360 | 11.0 | 330 | 1.20 | 3.60 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ12003300-2S0120-0360 | 12.0 | 330 | 1.20 | 3.60 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ13003300-2S0120-0360 | 13.0 | 330 | 1.20 | 3.60 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ14003300-2S0150-0500 | 14.0 | 330 | 1.50 | 5.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ15003300-2S0150-0500 | 15.0 | 330 | 1.50 | 5.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ16003300-2S0150-0500 | 16.0 | 330 | 1.50 | 5.00 | h6 | 0, +5 | ±0.15 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ17003300-2S0200-0620 | 17.0 | 330 | 2.00 | 6.20 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ18003300-2S0200-0620 | 18.0 | 330 | 2.00 | 6.20 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ19003300-2S0200-0620 | 19.0 | 330 | 2.00 | 6.20 | h6 | 0, +5 | ±0.20 | +0/-0.30 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ20003300-2S0200-0620 | 20.0 | 330 | 2.00 | 6.20 | h6 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ21003300-2S0200-0620 | 21.0 | 330 | 2.00 | 6.20 | h6 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ22003300-2S0200-0620 | 22.0 | 330 | 2.00 | 6.20 | h6 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ23003300-2S0200-0750 | 23.0 | 330 | 2.00 | 7.50 | h6 | 0, +5 | ±0.20 | +0/-0.40 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ24003300-2S0200-0750 | 24.0 | 330 | 2.00 | 7.50 | h6 | 0, +5 | ±0.20 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ25003300-2S0200-0750 | 25.0 | 330 | 2.00 | 7.50 | h6 | 0, +5 | ±0.20 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ26003300-2S0200-0750 | 26.0 | 330 | 2.00 | 7.50 | h6 | 0, +5 | ±0.20 | +0/-0.50 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

- Contact

Our team is ready to provide support

Truer Carbide is committed to providing efficient solutions to problems. Each team member has the expertise and experience to quickly understand and meet your needs.