Твердосплавные вставки являются невоспетыми героями точной обработки, позволяя производителям создавать высококачественные детали во всех отраслях промышленности. Если вы машинист, инженер или просто любопытный человек, интересующийся металлорежущими инструментами, это руководство расскажет вам о твердосплавных пластинах. Мы рассмотрим их состав, типы, свойства, области применения и многое другое в очень подробной, увлекательной и разговорной манере.

Что такое твердосплавные вставки?

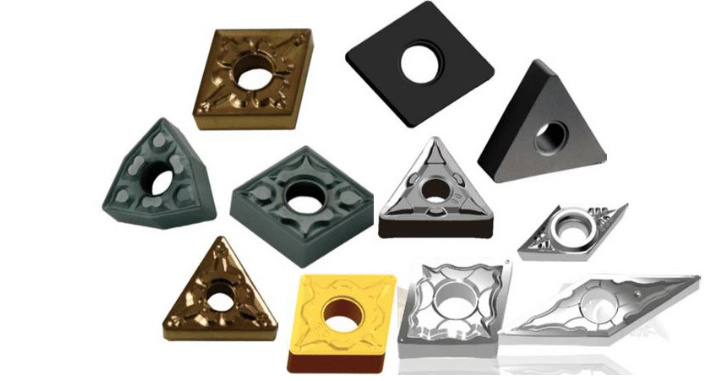

Твердосплавные вставки - это небольшие прецизионные инструменты, используемые в механической обработке для резки, придания формы и доводки материалов. Эти вставки, обычно изготовленные из порошка карбида вольфрама, обеспечивают долговечность и эффективность при обработке твердых материалов, таких как сталь, чугун и сплавы. Считайте их острыми зубьями на кромке мощного инструмента, предназначенного для того, чтобы оставаться острым под огромным давлением.

Виды твердосплавных вставок и их применение

Твердосплавные пластины бывают различных форм, марок и с различными покрытиями для удовлетворения конкретных потребностей в обработке. Ниже приведена таблица, демонстрирующая типы твердосплавных пластин и их типичные применения.

| Тип | Описание | Приложения |

|---|---|---|

| Токарные вставки | Предназначены для точных токарных работ. Часто имеют треугольную, квадратную или ромбовидную форму. | Токарные работы, обработка контуров и профилирование. |

| Фрезерные вставки | Пластины, используемые во фрезах для эффективного удаления материала. | Фрезерование пазов, торцевое фрезерование и обработка поверхности. |

| Буровые вставки | Высокопрочные вставки, обеспечивающие точность при сверлении отверстий. | Создание отверстий в твердых металлах. |

| Паяные вставки | Крепятся к инструментам и обеспечивают отличную производительность по низкой цене. | Обработка общего назначения. |

| Вставки для обработки канавок | Специально разработаны для обработки канавок и резьбы. | Создание канавок, пазов и резьбы. |

| Вставки для обработки деталей | Оптимальна для выполнения разделительных операций с чистыми срезами. | Отделение заготовок от исходного материала. |

| Резьбонарезные вставки | Точные вставки для создания резьбы на материалах. | Внутренняя и внешняя резьба. |

| Вставки с покрытием | Пластины с покрытием TiN, TiCN или Al2O3 для увеличения срока службы инструмента. | Высокоскоростная обработка, жаропрочные применения. |

| Керамические вставки | Не содержит карбида, но часто используется в паре для специализированной обработки с повышенной износостойкостью. | Высокотемпературная обработка закаленных материалов. |

| Вставки с алмазными наконечниками | Наконечник с поликристаллическим алмазом обеспечивает непревзойденную точность резки и долговечность. | Обработка цветных материалов и композитов. |

Сырье и состав Твердосплавные вставки

Твердосплавные вставки в основном состоят из карбида вольфрама, соединения, образованного из вольфрама и углерода. Вот описание типичного сырья и состава:

| Компонент | Роль | Процент (типичный) |

|---|---|---|

| Карбид вольфрама (WC) | Обеспечивает твердость и износостойкость. | 70-97% |

| Кобальт (Co) | Действует как связующее вещество, удерживающее зерна карбида вместе. | 3-20% |

| Карбид титана (TiC) | Повышает термостойкость и прочность. | 0-10% |

| Карбид тантала (TaC) | Повышает устойчивость к высоким температурам. | 0-5% |

Точный состав зависит от предполагаемого применения вставки, баланса между твердостью, прочностью и устойчивостью к термическому и механическому износу.

Технологический процесс производства твердосплавных пластин

Вы когда-нибудь задумывались, как создаются эти крошечные чудеса? Этот процесс очень сложен и гарантирует, что каждый вкладыш соответствует строгим стандартам.

- Подготовка порошка

Карбид вольфрама, кобальт и другие добавки смешиваются в мелкий порошок. - Уплотнение

Под высоким давлением порошок прессуется в пресс-форме для формирования нужной формы вставки. - Агломерация

Спрессованные формы нагреваются до высоких температур (около 1400°C), чтобы связать частицы, создавая твердый, плотный материал. - Шлифование и формообразование

Спеченные вставки обтачиваются до точной геометрии с помощью инструментов с алмазными наконечниками. - Покрытие

В зависимости от области применения вставки могут быть покрыты такими материалами, как нитрид титана или оксид алюминия. - Инспекция и упаковка

Перед отправкой каждая вставка проходит строгий контроль качества для обеспечения точности размеров и производительности.

Применение Твердосплавные вставки

Твердосплавные вставки незаменимы во многих отраслях промышленности. Вот таблица с описанием их применения:

| Промышленность | Приложение | Примеры заданий |

|---|---|---|

| Автомобильная промышленность | Прецизионная обработка деталей двигателя. | Коленчатые валы, распределительные валы, шестерни. |

| Аэрокосмическая промышленность | Обработка легких, жаропрочных материалов. | Авиационные компоненты, лопатки турбин. |

| Производство | Общая металлообработка и изготовление изделий. | Инструменты, пресс-формы и промышленное оборудование. |

| Нефть и газ | Обработка коррозионностойких материалов для жестких условий эксплуатации. | Клапаны, трубопроводы, буровое оборудование. |

| Медицина | Создание высокоточных медицинских инструментов. | Имплантаты, хирургические инструменты. |

Свойства материалов твердосплавных вставок

Твердосплавные вставки должны обеспечивать баланс между твердостью, вязкостью и износостойкостью. Вот обзор свойств их материалов:

| Недвижимость | Описание | Типичное значение |

|---|---|---|

| Твердость | Устойчивость к деформации. | 1,500-2,200 HV |

| Прочность на сжатие | Способность выдерживать сжимающие нагрузки. | 4,000 МПа |

| Вязкость разрушения | Способность противостоять распространению трещин. | 8-14 МПа-м½ |

| Плотность | Масса на единицу объема. | 13-15 г/см³ |

| Теплопроводность | Способность проводить тепло. | 70-100 Вт/мК |

Как выбрать подходящую твердосплавную вставку

Выбор подходящей вставки может показаться непосильной задачей, но все дело в балансе между потребностями в обработке. Примите во внимание следующие факторы:

| Фактор | Описание | Пример выбора |

|---|---|---|

| Тип материала | Что вы обрабатываете - сталь, алюминий или что-то другое? | Сталь: Вставки с покрытием. |

| Тип операции | Вы точите, фрезеруете, сверлите или нарезаете резьбу? | Нарезание резьбы: Резьбонарезные вставки. |

| Скорость и подача | Для высоких скоростей нужны прочные вставки с жаростойкими покрытиями. | Высокоскоростной: с покрытием TiAlN. |

| Срок службы инструмента | Что важнее - долговечность или экономичность? | Более длительный срок службы инструмента: Кермет. |

Преимущества и ограничения Твердосплавные вставки

| Преимущества | Ограничения |

|---|---|

| Исключительная твердость и износостойкость. | Может быть хрупким при сильных ударах. |

| Универсален для различных материалов и применений. | Более высокая первоначальная стоимость по сравнению с инструментами из быстрорежущей стали. |

| Повышенная точность и качество обработки поверхности. | Требует особых условий обработки. |

Поставщики и цены на твердосплавные вставки

| Поставщик | Расположение | Цена (за вставку) |

|---|---|---|

| Sandvik Coromant | Глобальная | $10-$50 |

| Kennametal | Глобальная | $8-$40 |

| Mitsubishi Materials | Япония | $12-$45 |

| Искар | Израиль | $15-$60 |

| Инструменты Seco | Швеция | $10-$55 |

Вопросы и ответы

| Вопрос | Ответить |

|---|---|

| Какие материалы могут резать твердосплавные пластины? | Они идеально подходят для обработки таких металлов, как сталь, нержавеющая сталь, чугун и цветные сплавы. |

| Каков срок службы твердосплавных пластин? | Срок службы зависит от условий эксплуатации, но высококачественные пластины обычно служат дольше, чем инструменты из быстрорежущей стали, благодаря повышенной износостойкости. |

| Можно ли перетачивать твердосплавные пластины? | Нет, они одноразовые. Вместо повторной заточки вы заменяете вставку. |

| Какие покрытия доступны для твердосплавных пластин? | Распространенные покрытия включают TiN (нитрид титана), TiCN (карбонитрид титана) и Al2O3 (оксид алюминия) для повышения износостойкости и теплоотвода. |