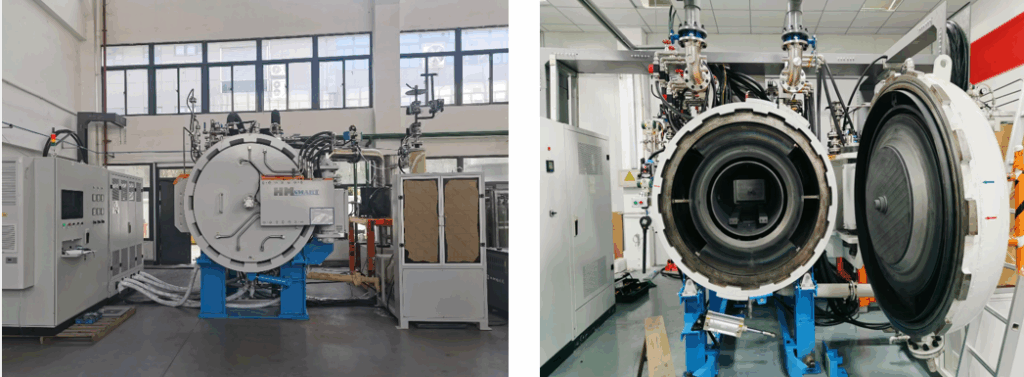

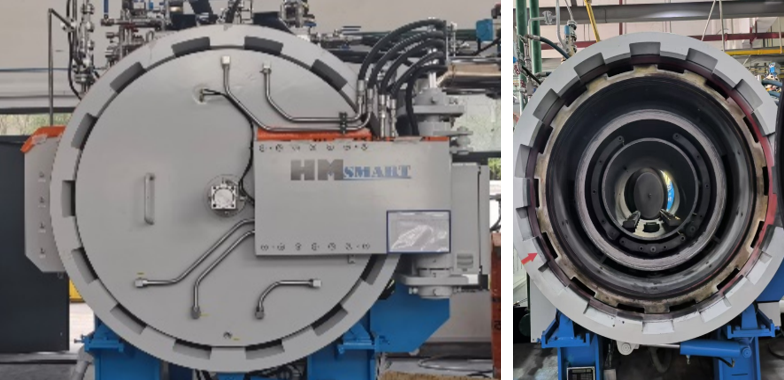

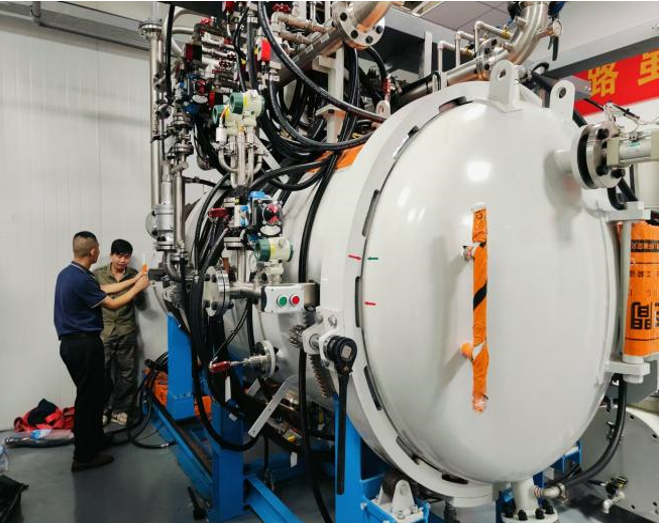

진공 및 압력 소결로

진공 및 압력 소결로는 금속 또는 세라믹 재료 분말을 열로 응고시켜 부품을 생산하는 공정으로, 진공 또는 가스 보호 분위기에서 재료 용융 온도 이하로 압력을 가하는 경우도 있습니다.

많은 재료의 경우 고온에서만 소결이 이루어질 수 있으므로 산화를 방지하기 위해 진공 또는 보호 분위기에서 소결을 수행해야 합니다. 당사의 진공 소결로는 텅스텐 카바이드 및 기타 금속 또는 세라믹의 고품질 소결을 위한 최상의 대안을 제공합니다. 텅스텐 카바이드와 같은 경질 금속 분말은 당사의 진공 또는 진공 과압 소결로를 사용하여 액상 소결 공정에서 처리할 수 있는 좋은 예입니다.

TRUER 소결로는 경금속(초경합금) 또는 기술 세라믹의 압력 가스(최대 200bar) 하에서 탈왁싱, 진공 소결 및 후속 등방성 치밀화를 결합합니다.

애플리케이션

탈왁싱 및 소결

- 진공 또는 Ar, N2 및 H2에 의한 부분 압력 하에서

- 압력 제어 모니터 포함

- 를 사용하여 바인더를 모니터링합니다.

- 고압 고속 냉각 옵션

재료

- 경금속(텅스텐 카바이드)

- 서멧

- PM- 특수 합금

- 테크니컬 세라믹

혜택

- 진공 및 압력 작동 모두에서 탁월한 온도 균일성 제공

- 에너지 및 가스 절약 설계를 통한 비용 효율성

- 강력하고 빠른 냉각으로 프로세스 시간 단축

- 이중 탈왁싱 시스템, 고효율, 신뢰성, 긴 서비스 수명

- 스마트한 설계, 간편한 작동, 짧은 시운전 시간

- 다른 크기 또는 사용자 지정 유형을 사용할 수 있습니다.

기술 매개 변수

용광로 유형 3312

| 매개변수 | 사양 |

| 사용 가능한 공간 | 300×300×1250mm |

| 최대. 온도 | 1600℃ |

| 충전 부하 | 최대 260kg |

| 작동 압력 | 0.6 MPa |

| 난방 전력 | 180 KW |

| 가스 매체 | Ar, N2 및 H2 |

| 빠른 냉각 시간 | 빈 용광로에서 1500℃에서 100℃까지 0.6MPa로 25분간 진행 |

| 온도 균일성 | 5℃ 미만 |

| 열전대 | 듀얼 코어 텅스텐 레늄(WRe5.26) |

용광로 유형 5518

| 매개변수 | 사양 |

| 사용 가능한 공간 | 500×500×1800 mm |

| 최대. 온도 | 2200℃ |

| 충전 부하 | 최대 1500kg |

| 작동 압력 | 6 MPa |

| 난방 전력 | 440 KW |

| 가스 매체 | Ar, N2 |

| 냉각 시간 | 빈 용광로에서 1900℃에서 100℃까지 8시간 동안 5.8MPa로 가열 |

| 온도 균일성 | 5℃ 미만 |

| 열전대 | 듀얼 코어 텅스텐 레늄(WRe5.26) |

용광로 유형 4416

| 사용 가능한 공간: | 400X400X1650mm |

| 최대. 온도: | 1600℃ |

| 충전 로드: | 최대 800kg |

| 작동 압력: | 0.6MPa |

| 히팅 파우더: | 180KW |

| 가스 매체: | Ar, N2 및 H2 |

| 빠른 냉각 시간: | 0.6MPa의 빈 용광로에서 1500℃에서 100℃까지 25분간 진행 |

| 온도 균일성: | 5℃ 미만 |

| 열전대: | 듀얼 코어 텅스텐 레늄(WRe5.26) |

용광로 유형 2212

| 사용 가능한 공간: | 200X200X1200mm |

| 최대. 온도: | 2200℃ |

| 충전 로드: | 최대 200kg |

| 작동 압력: | 6MPa |

| 히팅 파우더: | 440KW |

| 가스 매체: | Ar, N2 및 H2 |

| 냉각 시간: | 빈 용광로에서 1900℃에서 100℃까지 8시간 동안 5.8MPa에서 5.8시간 |

| 온도 균일성: | 5℃ 미만 |

| 열전대: | 듀얼 코어 텅스텐 레늄(WRe5.26) |

장점

진공 소결 직후 50bar(약 5MPa)의 고압 가스(일반적으로 아르곤 또는 질소와 같은 불활성 가스)가 도입됩니다. 이는 상당하고 유익한 압력 보조 소결 효과를 생성할 수 있습니다. 이를 일반적으로 가스 압력 소결 또는 저압 소결이라고 합니다. HIP와는 근본적으로 다르지만 단일 진공 소결보다 더 낮은 비용과 더 간단한 공정으로 더 나은 효과를 얻을 수 있습니다.

진공 소결 + 50bar 가스 압력 조합의 효과:

> 치밀화를 더욱 촉진하고, 남은 상호 연결된 기공을 붕괴시키거나 부분적으로 기공을 닫고, 입자 재배열 및 물질 이동을 촉진합니다.

> 닫힌 세포의 형성과 기공 구상화를 가속화하여 단순히 다공성을 줄이는 것보다 재료의 인성 및 피로 성능을 개선하는 데 더 효과적일 수 있습니다.

> 휘발성 원소 손실 억제(주요 장점!), 특히 특수 합금(일부 황동, 청동, 고속강, 스테인리스강 등) 또는 휘발성 원소(아연 Zn, 카드뮴 Cd, 망간 Mn, 크롬 Cr 등)가 포함된 일부 합금의 경우 더욱 효과적입니다.

> 표면 품질 개선, 원소의 휘발을 억제하여 휘발로 인한 표면 구멍과 불균일한 조성을 방지하여 더 매끄럽고 균일한 표면을 구현합니다.

> 어느 정도의 보호 분위기를 제공하고, 고온에서 소결체의 이차 산화 또는 탈탄(특히 철 기반 재료의 경우)을 방지합니다.