단일 공작물 습식 샌드 블라스팅 기계

The single-workpiece wet sandblasting machine is a unit-type automatic machine for individual surface treatment and honing of carbide inserts, which can achieve stable processing by simply replacing the material tray.

The machine is designed to perform honing, pre-coating treatment, and post-coating treatment on the cutting edges of carbide inserts through wet blasting.

It is mainly applied to inserts with incircle diameters ranging from 6.35 to 25.4mm and thicknesses from 2.4 to 9.5mm, excluding inserts without inner hole.

Operation Vidio

Structure

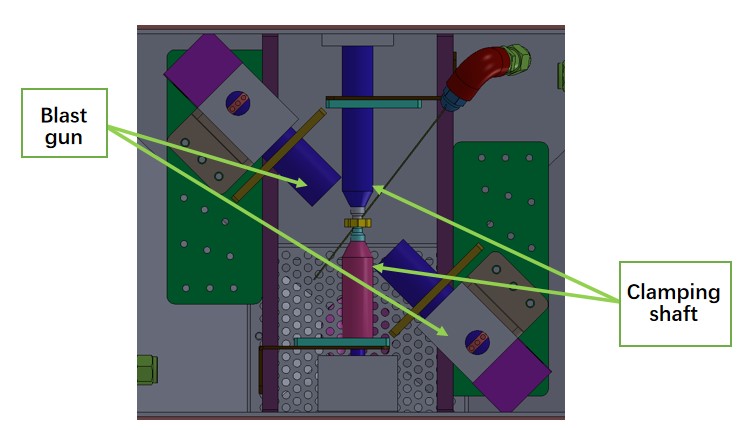

Blasting cabinet

- Insert the workpiece and rotate the workpiece while using the blast gun for sandblasting treatment.

- Adjust the appropriate angle according to different recipes and inserts.

- Adapt to different types of inserts by replacing the chuck.

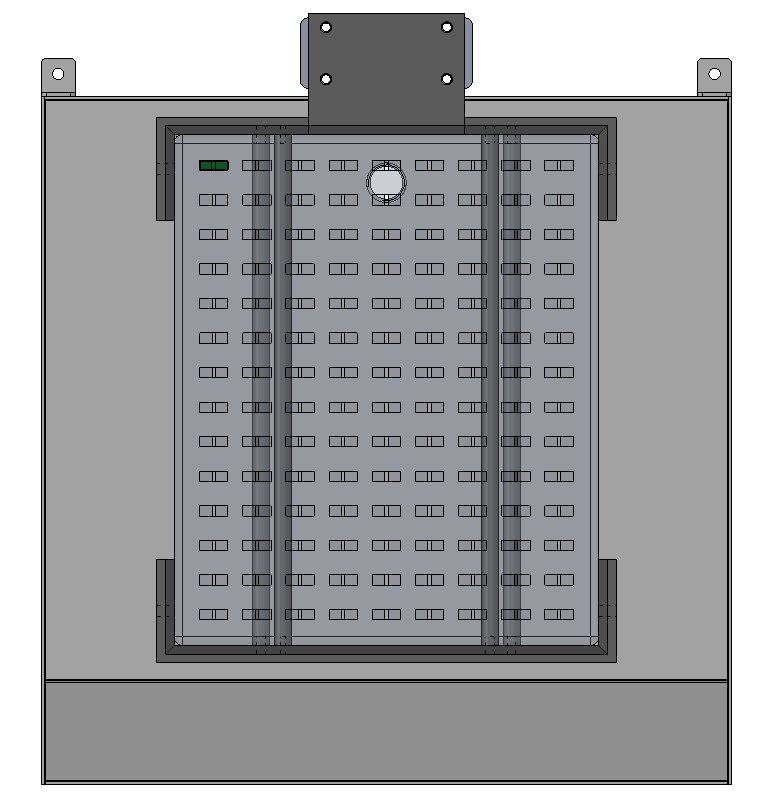

Tray Storage

- For placing trays, untreated and treated inserts are placed on the same tray, with the entire tray submerged in water to prevent oxidation.

- Different trays can be replaced according to the shape of the inserts.

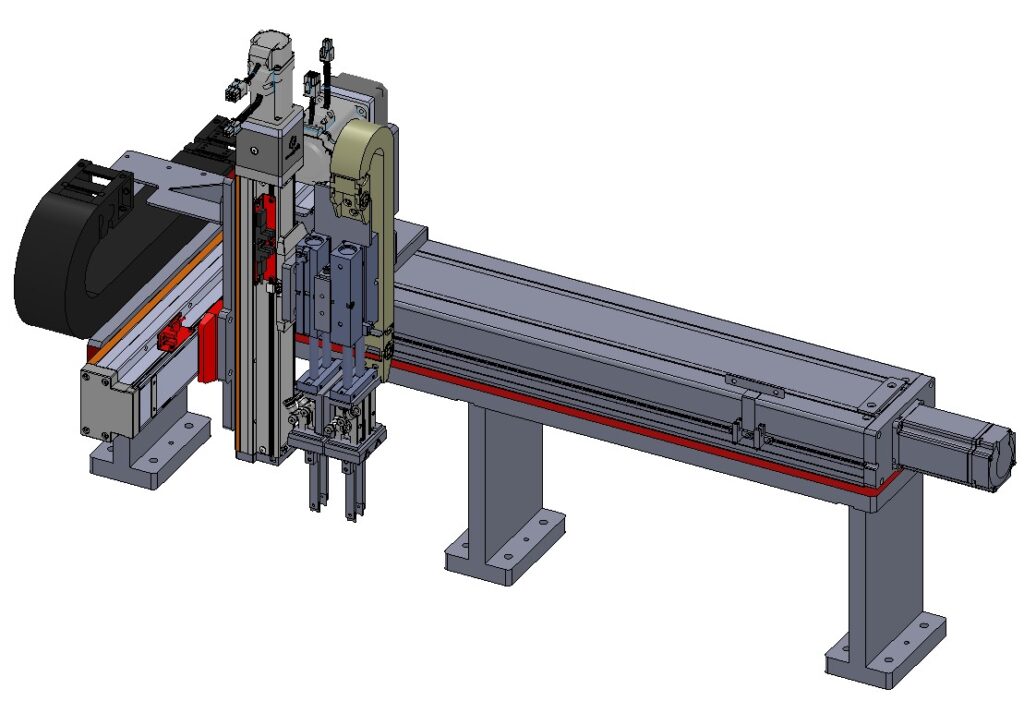

Robot for insert picking and moving

- > The untreated inserts in the tray are clamped and moved to the sandblasting tank, and the treated inserts are clamped back into the tray by robot.

- > The robot has axises of X, Y, and Z. It’s powered by servo motors for better positioning and accuracy of blasting.

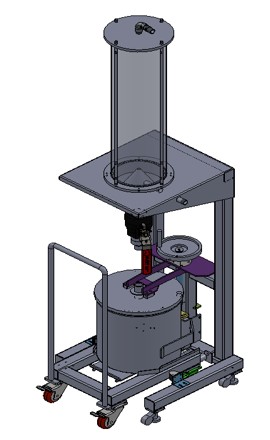

Waste sand recycling device

- The waste sand from the vortex separator in the equipment is separated into this device, where the waste sand settles to the bottom of the tank, and the clean water is recycled back to the slurry tank.

Dust collecting fan

The equipment is fitted with a dust collection system, which can effectively collect the sand mist generated during the sandblasting process.