정밀 엔지니어링 및 제조 분야에서는 아주 작은 불일치도 중대한 결과를 초래할 수 있습니다. 바로 여기서 맞춤형 크기 카바이드 심 플레이트 가 등장하여 다양한 애플리케이션에 탁월한 정확성과 내구성을 제공합니다. 얇고 세심하게 제작된 이 플레이트는 정밀한 정렬을 달성하고 마모를 보정하며 까다로운 환경에서 최적의 성능을 보장하는 데 필수적입니다.

이 종합 가이드에서는 맞춤형 초경 심 플레이트의 특성, 응용 분야, 장점, 올바른 공급업체를 선택하는 것이 큰 차이를 만드는 이유를 살펴보며 맞춤형 초경 심 플레이트의 세계를 자세히 살펴봅니다.

맞춤형 카바이드 심 플레이트는 무엇인가요?

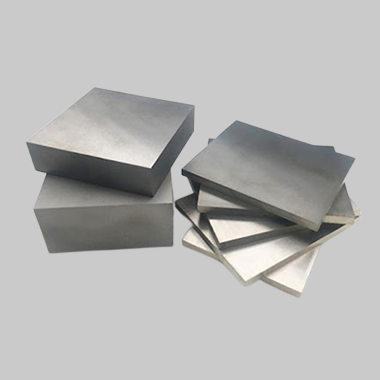

카바이드 심 플레이트는 일반적으로 매우 단단하고 내마모성이 뛰어난 소재인 텅스텐 카바이드로 제작되는 정밀 엔지니어링 부품입니다. 이 플레이트는 수천분의 1 인치만큼 얇은 다양한 두께로 제공되며, 특정 크기와 모양 요구 사항을 충족하도록 맞춤 제작할 수 있습니다.

카바이드 심 플레이트의 작동 원리: 정밀 조정의 과학

카바이드 심 플레이트는 두 부품 사이에 정확한 간격을 만들어주는 역할을 합니다. 엔지니어는 특정 두께의 심 플레이트를 삽입하여 정확한 정렬을 달성하고, 제조 공차를 보정하거나, 움직이는 부품 사이의 간격을 조정할 수 있습니다.

산업 전반의 애플리케이션: 정밀도가 가장 중요한 분야

맞춤형 크기의 카바이드 심 플레이트는 다음과 같은 다양한 산업 분야에서 활용되고 있습니다:

- 항공우주: 항공기 엔진, 터빈, 제어 시스템의 정밀한 정렬을 보장합니다.

- 자동차: 밸브 간극, 베어링 공차 및 기타 중요한 구성 요소를 조정합니다.

- 제조: 툴링, 고정 장치 및 기계 제작에서 정밀한 정렬과 공차를 달성하는 데 사용됩니다.

- 의료 기기: 수술 기구, 임플란트, 진단 장비에 정확한 간격을 만듭니다.

- 에너지 생산: 터빈, 펌프 및 기타 장비에서 최적의 간격과 성능을 유지하기 위해 사용됩니다.

카바이드 심 플레이트 속성: 자세히 살펴보기

| 기능 | 설명 |

|---|---|

| 재질 | 일반적으로 텅스텐 카바이드는 뛰어난 경도와 내마모성으로 잘 알려져 있습니다. |

| 두께 | 0.0005인치(0.0127mm) 이하까지 다양한 두께로 제공됩니다. |

| 표면 마감 | 특정 표면 거칠기 요구 사항을 달성하기 위해 연마, 랩핑 또는 연마할 수 있습니다. |

| 평탄도 | 매우 평평하고 평행한 표면은 정밀한 정렬과 균일한 하중 분포를 보장합니다. |

| 정확도 | 대개 ±0.0001인치(0.00254mm) 이상의 엄격한 허용 오차에 따라 제조됩니다. |

표 1: 카바이드 심 플레이트의 주요 특성

카바이드 심 플레이트 사용의 장점: 왜 정밀도를 선택해야 할까요?

- 탁월한 내구성: 카바이드의 고유한 경도와 내마모성은 까다로운 환경에서도 오래 지속되는 성능을 보장합니다.

- 정밀한 정렬: 얇은 맞춤형 크기의 플레이트는 장비 기능을 최적화하는 데 중요한 매우 정밀한 조정이 가능합니다.

- 수명 증가: 심은 마모를 고르게 분산시켜 부품의 수명을 연장하고 유지보수 비용을 절감하는 데 도움이 됩니다.

- 다용도성: 다양한 크기, 모양, 두께로 제공되므로 다양한 애플리케이션 요구 사항을 충족할 수 있습니다.

맞춤형 카바이드 심 플레이트 제조: 최고의 정밀 엔지니어링

맞춤형 크기의 카바이드 심 플레이트를 생산하려면 다음과 같은 일련의 특수 가공 공정이 필요합니다:

- 재료 선택: 애플리케이션의 특정 요구 사항에 따라 적절한 등급의 텅스텐 카바이드를 선택합니다.

- 블랭킹: 카바이드 재료를 최종 치수보다 약간 큰 거친 블랭크로 자릅니다.

- 소결: 블랭크를 압력 하에서 고온으로 가열하여 카바이드 입자를 결합하여 견고하고 밀도가 높은 재료를 만듭니다.

- 연삭: 정밀 연삭기를 사용하여 원하는 두께와 표면 마감을 구현합니다.

- 랩핑: 표면 평탄도와 평행도를 매우 엄격한 허용 오차로 더욱 세밀하게 조정합니다.

- 검사: 엄격한 품질 관리 검사를 통해 각 심 플레이트가 지정된 치수 및 표면 마감 요구 사항을 충족하는지 확인합니다.

카바이드 심 플레이트의 종류: 옵션 살펴보기

- 솔리드 카바이드 심 플레이트: 전체가 솔리드 카바이드로 제작되어 최고의 경도와 내마모성을 제공합니다.

- 카바이드 팁 심 플레이트: 저렴한 기판 재료에 납땜된 카바이드 팁이 특징이며, 특정 지점에서 내마모성이 필요한 애플리케이션에 비용 효율적인 솔루션을 제공합니다.

시장 동향: 정밀도에 대한 수요 증가

카바이드 심 플레이트의 글로벌 시장은 다음과 같은 요인에 힘입어 꾸준히 성장하고 있습니다:

- 자동화 향상: 자동화된 제조 공정에서는 정밀한 정렬과 공차가 요구되므로 고품질 심 플레이트가 필요합니다.

- 엄격한 업계 표준: 항공우주 및 의료 기기와 같은 산업은 엄격한 품질 및 안전 규정을 준수해야 하므로 카바이드 심 플레이트와 같이 안정적이고 내구성이 뛰어난 부품을 사용해야 합니다.

- 효율성에 집중하세요: 맞춤형 크기의 심 플레이트는 장비 성능을 최적화하고 가동 중단 시간을 줄이며 구성 요소 수명을 연장하여 전반적인 운영 효율성에 기여합니다.

공급업체 비교: 적합한 공급업체 찾기

| 공급업체 | 위치 | 가격 범위(개당, 대략적인 가격) | 스페셜티 |

|---|---|---|---|

| TRUER | 글로벌 | $10 - $50+(크기, 재질 및 복잡성에 따라 다름) | 다양한 재료와 크기, 신속한 프로토타입 제작, 맞춤형 솔루션 |

| 케나메탈 | US | $15 – $60+ | 고성능 코팅, 복잡한 형상 |

| 샌드빅 코로만트 | 스웨덴 | $20 – $75+ | 고급 소재, 애플리케이션별 솔루션 |

| ISC 도구 | US | $12 – $55+ | 표준 및 맞춤형 크기, 빠른 처리 시간 |

표 2: 카바이드 심 플레이트 공급업체 비교

장점과 단점: 장단점 비교

| 장점 | 단점 |

|---|---|

| 높은 정밀도 | 다른 재료에 비해 높은 비용 |

| 탁월한 내구성 | 제한된 유연성 |

| 광범위한 애플리케이션 | 충격에 취약할 수 있음 |

표 3: 카바이드 심 플레이트의 장점과 단점

관련 구성 요소: 정밀도 툴킷 확장

- 카바이드 마모 플레이트: 마모와 마모로부터 표면을 보호하는 데 사용되는 더 크고 두꺼운 플레이트입니다.

- 카바이드 스페이서: 어셈블리에서 자주 사용되는 구성 요소 사이의 간격을 정확하게 지정합니다.

- 카바이드 부싱: 회전하는 애플리케이션에서 마찰과 마모를 줄이는 데 사용되는 원통형 부품입니다.

맞춤형 사이즈의 카바이드 심 플레이트가 필요한 경우 TRUER를 선택해야 하는 이유는 무엇입니까?

- 타협하지 않는 품질: 당사는 최고 품질의 카바이드 소재만을 사용하고 제조 공정 전반에 걸쳐 엄격한 품질 관리 조치를 취합니다.

- 정밀 엔지니어링: 최첨단 장비와 숙련된 엔지니어가 정밀한 치수와 엄격한 허용 오차를 보장합니다.

- 사용자 지정 전문성: 전문 분야 맞춤형 크기 심 플레이트고객과 긴밀히 협력하여 고객의 고유한 사양을 충족합니다.

- 경쟁력 있는 가격: 당사는 경쟁력 있는 가격을 제공하며 투자 대비 최고의 가치를 제공하기 위해 노력합니다.

- 탁월한 고객 서비스: 저희 전담팀은 사용자 경험 전반에 걸쳐 신속하고 풍부한 지식을 갖춘 지원을 제공하기 위해 최선을 다하고 있습니다.

자주 묻는 질문: 카바이드 심 플레이트 관련 질문에 대한 답변

1. 가장 얇은 카바이드 심 플레이트는 무엇인가요?

카바이드 심 플레이트는 특정 요구 사항에 따라 0.0005인치(0.0127mm) 또는 그보다 더 얇은 공차까지 매우 얇게 제조할 수 있습니다.

2. 내 애플리케이션에 적합한 심 플레이트 두께는 어떻게 결정하나요?

이상적인 두께를 결정하려면 원하는 간격, 결합 부품의 제조 공차, 예상되는 마모 등의 요소를 고려해야 합니다. 기술 전문가와 상담하거나 전문 측정 도구를 사용하면 최적의 심 플레이트 두께를 결정하는 데 도움이 될 수 있습니다.

3. 카바이드 심 플레이트를 고온 환경에서 사용할 수 있나요?

예, 카바이드 소재는 내열성이 뛰어나며 고온을 견딜 수 있습니다. 그러나 특정 온도 제한은 사용되는 카바이드의 등급에 따라 다릅니다.

4. 맞춤형 카바이드 심 플레이트의 일반적인 리드 타임은 어떻게 되나요?

리드 타임은 주문 규모, 복잡성, 현재 생산 능력 등의 요인에 따라 달라집니다. 하지만 많은 공급업체가 며칠에서 몇 주에 이르는 경쟁력 있는 리드 타임을 제공하기 위해 노력하고 있습니다.

5. 맞춤형 카바이드 심 플레이트에 대한 견적은 어떻게 요청하나요?

대부분의 공급업체는 견적을 요청할 수 있는 온라인 양식이나 연락처 정보를 제공합니다. 재료, 치수, 공차, 수량 등 세부 사양을 제공하면 정확하고 시기적절한 견적을 받는 데 도움이 됩니다.