PVD용 자동 스트링 머신

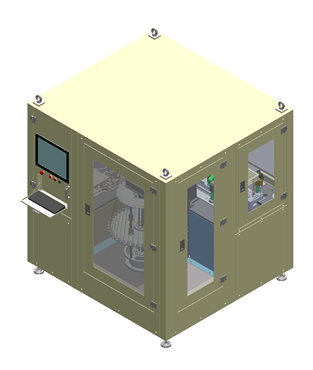

자동 스트링 머신은 카바이드 인서트 제조 산업을 위해 특별히 설계된 고도로 자동화된 장치입니다. 인서트와 비드의 스트링 조립을 완전 자동으로 수행합니다.

이 기계는 육안 검사, 정밀 그립, 자동 선삭 및 진동 부하와 같은 첨단 기술을 통합하여 생산 효율성과 제품 품질 일관성을 크게 향상시킵니다.

모듈식 디자인으로 빠르게 교체할 수 있으며 다양한 인서트와 스트링 비드에 적용할 수 있습니다. 안정적인 작동과 간편한 조작으로 기존의 수작업에 대한 이상적인 대안이 될 수 있습니다.

애플리케이션:

차원:

인서트와 트레이의 치수는 허용 오차 범위 내에 있어야 하며, 구체적인 치수는 고객이 제공한 기술 요구 사항에 따릅니다.

구멍이 있는 삽입: 구멍 지름: Φ3.2mm ~ Φ6.0mm 적용 가능

트레이 크기: 384土0.5mm X 282士0.5mm X 14土0.5mm, 96/204/408 그리드

스트링 로드: 길이 300-560mm 적용 가능, 직경 3-5mm 적용 가능(곡률 <1mm)

유형:

인서트와 트레이의 치수는 허용 오차 범위 내에 있어야 하며, 구체적인 치수는 고객이 제공한 기술 요구 사항에 따릅니다.

구멍이 있는 삽입: 구멍 지름: Φ3.2mm ~ Φ6.0mm 적용 가능

트레이 크기: 384土0.5mm X 282士0.5mm X 14土0.5mm, 96/204/408 그리드

스트링 로드: 길이 300-560mm 적용 가능, 직경 3-5mm 적용 가능(곡률 <1mm)

유형:

웨이트를 삽입합니다:

고객이 제공한 기술 요구 사항에 따라 1~30g입니다.

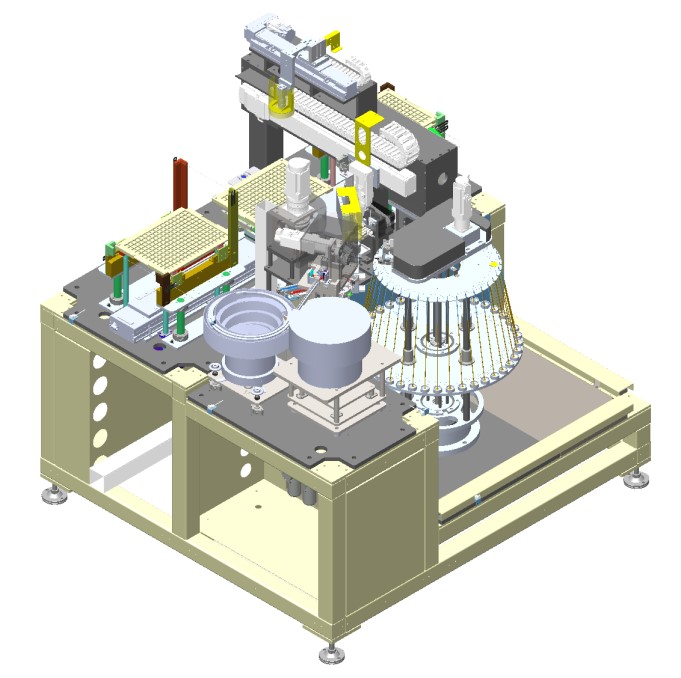

장비의 주요 구성 요소:

생산성:

스트링 효율: 18~25개/분. (평균)

정확성:

그립 정확도 > 99%

- 인서트 트레이의 로딩 및 언로딩 장치

- 인서트의 육안 검사 단위

- 인서트 그립 및 운반 로봇 유닛

- 인서트의 회전 단위

- 스트링 비드의 진동 하중 단위

- 인서트의 비드 및 로드 스트링의 로봇 유닛

- 스트링로드의 빈 단위

생산성:

스트링 효율: 18~25개/분. (평균)

정확성:

그립 정확도 > 99%