Applications in Jewelry Making

Jewelry may look delicate and dainty on the outside, but the tools behind the scenes? Oh, they’re anything but. The secret workhorses behind that sparkly ring or precision-cut pendant are tools made from one seriously tough material: 카바이드 로드. You may be thinking, “Rods? In jewelry?” Yes, and not just any rods—tungsten carbide rods, known for their insane hardness, edge retention, and thermal resistance.

Jewelers, especially those working with custom or luxury pieces, often demand tools that can handle intricate designs, repetitive work, and extreme accuracy. Carbide rods are the core material used in tools like burrs, drills, gravers, and milling cutters—pretty much the unsung heroes of precision shaping and engraving in metals like gold, platinum, and even titanium.

Picture a jeweler trying to carve a fine detail into a platinum ring. With a steel tool, the tip would dull after just a few tries. Enter carbide—cut once, cut right, and keep cutting for a long time. It’s the go-to for rotary tools, CNC machines, and high-precision lathes in fine jewelry workshops.

Carbide vs. Steel or Diamond Tools: The Showdown

So, let’s get real for a moment. If you’re a jeweler, do you go for 카바이드, 강철, or diamond tools? Here’s the scoop.

Steel tools are the old-school classics. They’re cheaper and easy to sharpen. But they dull fast, especially against harder metals. Think of steel like a butter knife—it does the job for soft materials but struggles with the tough stuff.

Diamond tools? These are the Ferraris of the tool world. Super precise, ultra-hard, and can work on even harder materials like ceramics and gemstones. But they’re expensive and fragile. Drop a diamond-coated tool, and it might chip. Not ideal in a fast-moving, hands-on workshop.

카바이드 로드, on the other hand, strike a balance. They’re harder than steel, almost up there with diamond in terms of cutting ability, but way more durable. They’re less brittle and more forgiving, especially in daily wear and tear. Want a tool that won’t need replacing every other month? Go carbide.

| 기능 | 스틸 도구 | Diamond-Coated Tools | Carbide Rod Tools |

|---|---|---|---|

| 경도 | 보통 | 매우 높음 | 매우 높음 |

| 내구성 | 낮음 | 취약한 | 우수 |

| 비용 | 낮음 | 매우 높음 | 보통에서 높음 |

| Ideal Use Case | Soft Metals | Gemstones/Ceramics | Hard Metals/Precision |

| Sharpening Ability | 쉬운 | Cannot Be Sharpened | Sharpenable with Tools |

How Jewelers Choose the Right Carbide Rod

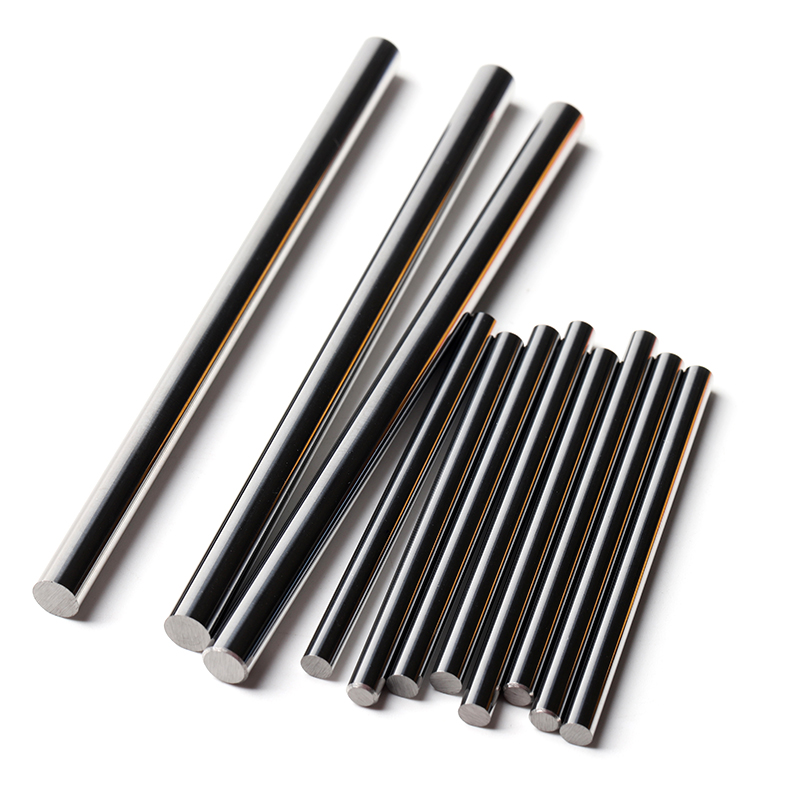

Choosing the right carbide rod isn’t just about grabbing the first shiny stick on the shelf. Jewelers weigh several factors:

- Rod Composition: Most opt for tungsten carbide-cobalt (WC-Co) combinations. The cobalt acts as a binder and adds strength.

- 입자 크기: Fine-grain carbide rods are preferred for delicate engraving work; coarse grains are better for durability and rough shaping.

- Tolerance and Finish: High-tolerance, polished rods work better in high-speed applications where every micron matters.

- 도구 호환성: Different tools need rods of different diameters and lengths. Jewelers often look for rods that fit rotary tools, Dremels, or CNC attachments.

A good jeweler knows their carbide like a chef knows their knives. They match the tool to the task.

사용 이유 카바이드 로드 in Jewelry Making?

Simple answer? They make your life easier.

Longer-lasting tools, cleaner cuts, and more consistent results. That’s what carbide rods bring to the table. When working with expensive or sensitive materials like gold or platinum, even the smallest error can cost hundreds. Carbide tools offer precision that helps avoid mistakes.

Plus, carbide is resistant to corrosion. No rust, no degradation—even if you leave your tools out in a slightly humid workshop. That’s peace of mind, especially for artisan jewelers who can’t afford tool failures in the middle of a custom job.

Carbide rods are also incredibly versatile. From engraving initials on wedding bands to sculpting bespoke metal pendants, there’s a carbide tool for every purpose.

Tungsten Carbide Applications in Artisan Jewelry Design

Now we’re talking art and soul. Artisan jewelers aren’t mass-producing pieces; they’re sculpting stories. For that, you need tools that respond like an extension of your hand.

텅스텐 카바이드 excels here because of its adaptability. Jewelers use it for:

- Micro-engraving: For those intricate, museum-worthy designs.

- Channel setting: Precision grooves to seat gemstones.

- Polishing and grinding wheels: Giving metals that luxurious, mirror-like finish.

- Custom die stamping: Creating one-of-a-kind shapes and patterns.

Here’s the thing—tungsten carbide doesn’t just perform well. It also adds to the aesthetic process. Knowing your tool won’t wobble, chip, or go blunt means the artist’s flow is uninterrupted.

Some boutique jewelers even design their own tools using raw carbide rods, machining them to custom specs. That’s dedication.

Top 10 Metal Powder Models for Carbide Rods Used in Jewelry Applications

Here’s a list of popular metal powder models used in manufacturing 카바이드 로드 suitable for jewelry-making tools:

| 파우더 모델 | 구성 하이라이트 | Ideal Application | Notable Traits |

|---|---|---|---|

| WC-Co 6% | 94% 텅스텐 카바이드, 6% 코발트 | Fine engraving, light cutting | Ultra-fine grain, high wear resistance |

| WC-Co 10% | 90% 텅스텐 카바이드, 10% 코발트 | General-purpose shaping | 강인함과 강인함의 균형 |

| WC-Ni 12% | 88% WC, 12% Nickel Binder | Corrosive environments (e.g., polishing) | High corrosion resistance, non-magnetic |

| WC-TiC-Co | WC + Titanium Carbide + Cobalt | High-speed cutting of hard metals | Enhanced wear and heat resistance |

| WC-Co 3% UF | Ultra-fine grain, 3% Cobalt | Engraving micro-patterns | Excellent edge retention and precision |

| WC-Co 15% | Coarser grain, 15% Cobalt | Rough shaping and grinding | 더 높은 인성, 더 낮은 경도 |

| WC-TaC-Co | Tantalum Carbide inclusion | Ultra-durable engraving tasks | Shock-resistant, premium performance |

| WC-ZrC-Co | Zirconium Carbide, 6% Cobalt | Precision groove cutting | Increased resistance to thermal fatigue |

| WC-CoCr | WC + Cobalt-Chromium alloy | High-wear polishing tools | Strong at high speeds, good for mirror polish |

| WC-Co HSA | High Strength Alloy | Die making for metal embossing | Superior impact resistance |

자주 묻는 질문

| 질문 | 답변 |

|---|---|

| What is a carbide rod used for in jewelry making? | Carbide rods are used in tools for cutting, engraving, polishing, and shaping metal components in jewelry. |

| Are carbide tools better than diamond for jewelry making? | Diamond tools are harder but more brittle; carbide offers durability, sharpness, and longevity with less risk of damage. |

| Can carbide tools be used on gold and silver? | Absolutely. Carbide tools are ideal for both soft metals like gold and harder metals like platinum or titanium. |

| Is tungsten carbide the same as titanium? | No. Tungsten carbide is denser, harder, and more wear-resistant. Titanium is lighter and more corrosion-resistant. |

| Do jewelers make custom carbide tools? | Yes. Some artisan jewelers craft or order custom carbide tools tailored to their techniques. |

| How long do carbide tools last? | With proper use, carbide tools can last months or even years, especially in fine detail work. |

| Are there eco-friendly options with carbide? | Recycled carbide is becoming more common, and some suppliers offer sustainable manufacturing practices. |

| Can carbide be used in gemstone settings? | Yes. Carbide tools are precise enough for creating settings for hard gemstones. |

| What is the main binder in carbide rods? | Typically cobalt or nickel, which holds the tungsten carbide grains together. |

| Can beginners use carbide tools? | Definitely! They offer consistent performance, which can help new jewelers develop precision skills. |