超硬チップ 超硬チップは、精密加工における縁の下の力持ちであり、メーカーがあらゆる産業において高品質な部品を製造することを可能にしています。機械工、エンジニア、金属切削工具に興味のある方、このガイドブックは超硬チップについて分かりやすく説明します。超硬チップの組成、種類、特性、用途など、非常に詳しく、魅力的で、会話が弾むような方法で探っていきましょう。

超硬インサートとは?

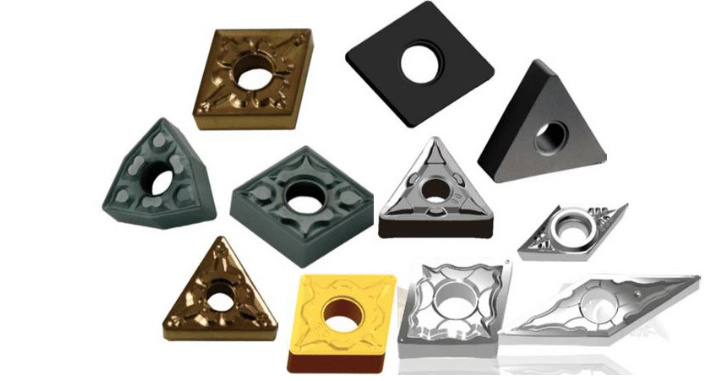

超硬チップは、材料を切削、成形、精錬する機械加工に使用される小型で精密な工具です。一般的に炭化タングステン粉末から作られるこれらのチップは、鋼、鋳鉄、合金などの硬い材料を加工する際に、耐久性と効率性を発揮します。莫大な圧力下でも鋭利さを保つように設計された、強力な工具の刃先の鋭利な歯とお考えください。

超硬インサートの種類と用途

超硬チップには、特定の加工ニーズに対応するため、さまざまな形状、材種、コーティングがあります。以下は、超硬チップの種類と代表的な用途を示した表です。

| タイプ | 説明 | アプリケーション |

|---|---|---|

| 旋削インサート | 旋盤作業で精度を出すために設計された。三角形、四角形、菱形が多い。 | 旋盤加工、輪郭加工、プロファイル加工。 |

| ミーリングインサート | 効率的に材料を除去するためにフライスカッターに使用されるインサート。 | スロッティング、フェースフライス加工、表面仕上げ。 |

| ドリリングインサート | 穴あけ精度を保証する高耐久性チップ。 | 硬い金属に穴を開ける。 |

| ろう付けインサート | 工具に固定され、低コストで優れた性能を発揮する。 | 汎用機械加工。 |

| 溝入れインサート | 溝加工とねじ切り加工用に特別に設計されています。 | 溝、スロット、スレッドの作成。 |

| パーティングインサート | きれいなカットのパーティングオフ作業に最適。 | ストック材からワークを切り離す。 |

| ねじ切りインサート | 材料にねじ山を形成するための精密なインサート。 | 内ネジと外ネジ。 |

| コーティング・インサート | TiN、TiCN、またはAl2O3でコーティングされたインサートは、工具寿命を延長します。 | 高速加工、耐熱用途。 |

| セラミックインサート | 非超硬合金だが、耐摩耗性を強化した特殊加工用によく使用される。 | 高硬度材の高温加工。 |

| ダイヤモンドチップインサート | チップには多結晶ダイヤモンドを使用し、比類のない切断精度と長寿命を実現。 | 非鉄材料と複合材料の加工。 |

原材料と成分 超硬インサート

超硬チップは、主にタングステンと炭素から形成される化合物である炭化タングステンから構成されています。その代表的な原材料と組成の内訳は以下の通りです:

| コンポーネント | 役割 | パーセント(代表値) |

|---|---|---|

| 炭化タングステン(WC) | 硬度と耐摩耗性を提供する。 | 70-97% |

| コバルト | 超硬合金の粒をまとめるバインダーとして働く。 | 3-20% |

| 炭化チタン(TiC) | 耐熱性と靭性を高める。 | 0-10% |

| 炭化タンタル(TaC) | 高温安定性を向上させる。 | 0-5% |

正確な配合は、インサートの用途によって異なり、硬度、靭性、耐熱性、耐機械摩耗性のバランスをとる。

超硬インサートの製造工程フロー

この小さな驚異がどのように作られるのか、不思議に思ったことはありませんか?その工程は複雑で、すべてのインサートが厳格な基準を満たすことを保証している。

- パウダーの準備

炭化タングステン、コバルト、その他の添加物を微粉末に混合する。 - コンパクション

この粉末を金型に押し込み、高圧をかけて目的のインサート形状を形成する。 - 焼結

圧縮された形状を高温(約1400℃)で加熱して粒子を結合させ、固体の緻密な材料を作る。 - 研磨と成形

焼結チップは、ダイヤモンドチップの工具を使って精密な形状に研削される。 - コーティング

用途によっては、窒化チタンや酸化アルミニウムのような材料でインサートをコーティングすることもある。 - 検査と梱包

各インサートは、出荷前に寸法精度と性能を保証するために厳格な品質管理を受けている。

応用例 超硬インサート

超硬チップは、多くの産業で欠かすことのできないものです。その用途を表にまとめてみました:

| 産業 | 申し込み | タスクの例 |

|---|---|---|

| 自動車 | エンジン部品の精密加工 | クランクシャフト、カムシャフト、ギア。 |

| 航空宇宙 | 軽量で耐熱性のある材料を加工する。 | 航空機部品、タービンブレード |

| 製造業 | 一般的な金属加工と製作。 | 工具、金型、産業機械 |

| 石油・ガス | 過酷な環境下での耐食性材料の加工。 | バルブ、パイプライン、掘削装置。 |

| メディカル | 高精度の医療器具を作る | インプラント、手術器具 |

超硬インサートの材料特性

超硬チップは、硬度、靭性、耐摩耗性のバランスが求められます。ここでは、その材料特性の概要を説明します:

| プロパティ | 説明 | 代表値 |

|---|---|---|

| 硬度 | 変形に対する耐性。 | 1,500-2,200 HV |

| 圧縮強度 | 圧縮荷重に耐える能力。 | 4,000 MPa |

| 破壊靭性 | 亀裂の進展に抵抗する能力。 | 8-14 MPa-m½ |

| 密度 | 単位体積当たりの質量。 | 13-15 g/cm³ |

| 熱伝導率 | 熱伝導能力。 | 70-100 W/mK |

正しい超硬インサートの選び方

適切なチップを選択することは、圧倒的に難しく感じるかもしれませんが、加工ニーズのバランスを取ることが重要です。以下の要素を考慮してください:

| ファクター | 説明 | 選択例 |

|---|---|---|

| 素材タイプ | 何を加工しているのですか?スチール、アルミニウム、それとも他の何か? | スチール:コーティングされたインサート。 |

| オペレーション・タイプ | 旋盤加工、フライス加工、穴あけ加工、ねじ切り加工をしていますか? | ねじ切り:ねじ切りインサート。 |

| 速度と送り速度 | 高速回転には、耐熱コーティングを施した耐久性のあるインサートが必要です。 | 高速:TiAlNコーティング。 |

| 工具寿命 | 寿命を優先するか、コスト効率を優先するか。 | 工具寿命が長い:サーメット |

の利点と限界 超硬インサート

| メリット | 制限事項 |

|---|---|

| 卓越した硬度と耐摩耗性。 | 強い衝撃を受けると脆くなることがある。 |

| 様々な素材や用途に対応。 | ハイス工具に比べてイニシャルコストが高い。 |

| 精度と表面仕上げの向上。 | 特定の加工条件が必要。 |

超硬インサートのサプライヤーと価格

| サプライヤー | 所在地 | 価格(インサート1枚あたり) |

|---|---|---|

| サンドビック・コロマント | グローバル | $10-$50 |

| ケナメタル | グローバル | $8-$40 |

| 三菱マテリアル | 日本 | $12-$45 |

| イスカー | イスラエル | $15-$60 |

| セコ・ツールズ | スウェーデン | $10-$55 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬チップはどのような材料を切削できますか? | 鋼、ステンレス鋼、鋳鉄、非鉄合金などの金属加工に最適です。 |

| 超硬チップの寿命は? | 寿命は使用方法によって異なるが、高品質のチップは耐摩耗性に優れているため、一般的にハイス工具よりも長持ちする。 |

| 超硬チップは再研磨できますか? | いいえ、使い捨てです。研ぎ直す代わりにインサートを交換します。 |

| 超硬チップにはどのようなコーティングがありますか? | 一般的なコーティングには、TiN(窒化チタン)、TiCN(炭窒化チタン)、耐摩耗性と放熱性を向上させるAl2O3(酸化アルミニウム)などがある。 |