Когда речь идет о промышленном оборудовании, долговечность и производительность не подлежат обсуждению. Независимо от того, занимаетесь ли вы добычей полезных ископаемых, строительством или производством, износ вашего оборудования может сделать или сломать ваши операции. Именно поэтому твёрдый сплав быстроизнашивающиеся детали вступают в игру. Эти компоненты - невоспетые герои тяжелой промышленности, обеспечивающие непревзойденную стойкость к истиранию, коррозии и ударам. Но что же такое твердосплавные изнашиваемые детали и почему они так важны?

Важность износостойких деталей из твердого сплава

Представьте, что вы бежите марафон в шлепанцах. Звучит болезненно, верно? Именно так выглядит использование некачественных материалов в промышленных условиях с высокой нагрузкой. Твердосплавные быстроизнашивающиеся детали Это как высокопроизводительные кроссовки в промышленном мире - они созданы для того, чтобы выдерживать экстремальные условия, не вытирая пота.

Эти детали необходимы, поскольку они значительно продлевают срок службы оборудования, сокращают время простоя и повышают общую эффективность. Подумайте: если ваше оборудование преждевременно выходит из строя, вы не только несете расходы на замену, но и теряете драгоценное время и производительность. Износостойкие детали из твердого сплава действуют как щит, защищая ваше оборудование от неумолимых сил трения, тепла и давления.

Но почему именно карбид? Ну, карбид, особенно карбид вольфрамаЭто композитный материал, изготовленный из вольфрама и углерода. Он невероятно тверд, уступая лишь алмазам, и обладает исключительной износостойкостью. Это делает его идеальным для применения там, где другие материалы просто рассыпаются под давлением.

Области применения карбида Износостойкие детали

Износостойкие детали из твердого сплава применяются не только в одной отрасли - они являются универсальными игроками в самых разных сферах. Вот краткая информация о том, где можно встретить эти прочные компоненты в действии:

- Горная промышленность и бурение: От буровых коронок до деталей дробилок - твердосплавные компоненты необходимы для разрушения прочных горных пород и минеральных образований.

- Строительство: Зубья экскаваторов, ножи бульдозеров и бетонорезы - все они выигрывают от долговечности твердого сплава.

- Производство: В таких отраслях, как автомобильная и аэрокосмическая, твердосплавные инструменты используются для резки, формовки и отделки металлических деталей.

- Сельское хозяйство: Лезвия плугов, зубья культиваторов и другое сельскохозяйственное оборудование часто полагаются на твердый сплав для обеспечения долговечности.

- Нефть и газ: В суровых условиях нефтяных вышек и трубопроводов твердосплавные детали противостоят коррозии и износу.

Это лишь несколько примеров, но список можно продолжить. По сути, если отрасль связана с тяжелым оборудованием и жесткими условиями эксплуатации, то твердосплавные изнашиваемые детали, скорее всего, играют в ней важную роль.

Почему стоит выбрать карбид вольфрама в качестве износостойкого материала для компонентов?

Итак, что же заставляет карбид вольфрама материал для износостойких деталей? Давайте разберемся:

- Твердость: Как уже говорилось, карбид вольфрама невероятно твердый. Это означает, что он может выдерживать абразивные нагрузки, которые быстро изнашивают другие материалы.

- Долговечность: Он не только противостоит износу, но и выдерживает экстремальное давление и удары. Это делает его идеальным для применения в условиях высоких нагрузок.

- Коррозионная стойкость: В отличие от некоторых металлов, карбид вольфрама не ржавеет и не подвергается коррозии даже в суровых условиях.

- Термостойкость: Он может выдерживать высокие температуры без потери структурной целостности, что очень важно для таких применений, как резка и сверление металла.

- Долголетие: Благодаря своей прочности детали из твердого сплава служат значительно дольше, чем изготовленные из других материалов, что снижает необходимость в их частой замене.

Одним словом, карбид вольфрама - это супергерой среди материалов: прочный, стойкий и готовый к любым испытаниям.

Что такое твердый сплав Износостойкие детали?

Чтобы лучше понять, что такое твердосплавные износостойкие детали, давайте подробнее рассмотрим, что они собой представляют и как их изготавливают.

| Аспект | Описание |

|---|---|

| Состав | Изготовлен из частиц карбида вольфрама, соединенных металлическим связующим, обычно кобальтом. |

| Производственный процесс | Порошковая металлургия: Порошки вольфрама и углерода смешиваются, прессуются и спекаются. |

| Свойства | Высокая твердость, износостойкость и прочность. |

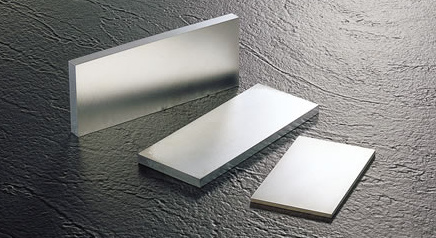

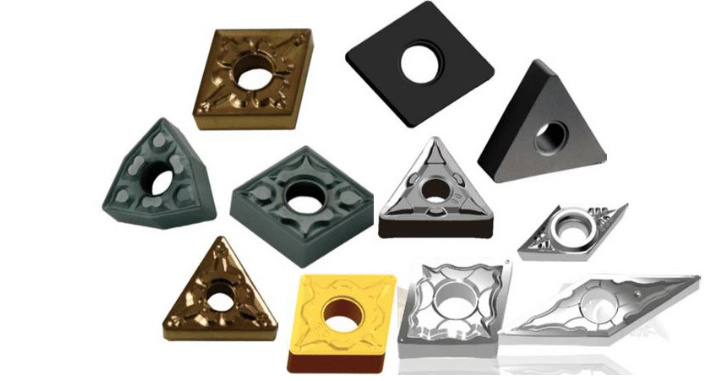

| Общие формы | Вставки, наконечники, лезвия, плашки и насадки. |

| Приложения | Используется в режущих инструментах, износостойких пластинах и компонентах промышленного оборудования. |

Преимущества износостойких деталей из карбида вольфрама

Почему вам стоит выбрать карбид вольфрама, а не другие материалы? Вот краткое сравнение:

| Преимущество | Описание |

|---|---|

| Превосходная износостойкость | Превосходит сталь и другие материалы в абразивных средах. |

| Высокая прочность | Выдерживает экстремальное давление и удары, не растрескиваясь. |

| Коррозионная стойкость | Хорошо работает во влажной или химически агрессивной среде. |

| Устойчивость к жаре | Сохраняет работоспособность при высоких температурах. |

| Экономически эффективный | Более длительный срок службы означает меньшее количество замен и меньшие долгосрочные затраты. |

Применение износостойких деталей из твердого сплава

Износостойкие детали из твердого сплава встречаются повсеместно, но давайте рассмотрим некоторые конкретные области применения:

- Сверла: Используемые в горнодобывающей промышленности и при бурении нефтяных скважин, буровые коронки с твердосплавными наконечниками с легкостью разрезают горную породу и металл.

- Режущий инструмент: В производстве твердосплавные пластины используются для точной резки и формовки металлов.

- Износостойкие пластины: Используются в конвейерных системах и желобах для защиты от абразивного износа.

- Форсунки: В таких отраслях, как пескоструйная обработка, твердосплавные сопла противостоят износу от абразивных частиц.

Как выбрать лучший твердый сплав Износостойкие детали?

Выбор подходящих износостойких деталей из твердого сплава может показаться непосильной задачей, но вот несколько советов, которые помогут вам в этом:

- Поймите свои потребности: С каким видом износа вы имеете дело? Абразивный, ударный или коррозионный?

- Качество материала: Ищите высококачественный карбид вольфрама с подходящим связующим (например, кобальтом или никелем).

- Дизайн и посадка: Убедитесь, что деталь разработана для конкретного применения и идеально подходит к вашему оборудованию.

- Репутация поставщика: Выбирайте поставщика с хорошей репутацией и опытом поставки долговечных и высокопроизводительных деталей.

Износостойкие детали из твердого сплава в сравнении с другими материалами

Чем карбид отличается от других материалов? Давайте сравним:

| Материал | Плюсы | Cons |

|---|---|---|

| Карбид вольфрама | Очень твердый, износостойкий, долговечный. | Более дорогостоящий аванс. |

| Сталь | Недорогие, широкодоступные. | Подвержены износу и коррозии. |

| Керамика | Твердый и износостойкий. | Хрупкий и склонный к растрескиванию при ударах. |

| Пластмассы | Легкий и устойчивый к коррозии. | Не подходит для применения в условиях высоких нагрузок. |

Специальные модели металлических порошков для карбида Износостойкие детали

При изготовлении износостойких деталей из твердого сплава решающее значение имеет качество используемого металлического порошка. Вот 10 конкретных моделей металлических порошков, каждый из которых обладает уникальными свойствами:

| Модель порошка | Описание |

|---|---|

| WC-6%Co | Карбид вольфрама с кобальтовой связкой 6%. Идеально подходит для износостойких деталей общего назначения. |

| WC-10%Co | Повышенное содержание кобальта для улучшения прочности. |

| WC-12%Co | Еще более прочный, подходит для применения в условиях сильных ударов. |

| WC-15%Co | Максимальная прочность, используется в экстремальных условиях. |

| WC-6%Ni | Никелевое связующее для повышения коррозионной стойкости. |

| WC-10%Ni | Повышенное содержание никеля для высокоагрессивных сред. |

| WC-6%Co-2%Cr | Для повышения износостойкости и коррозионной стойкости добавлен хром. |

| WC-8%Co-2%Cr | Сбалансированная прочность и износостойкость. |

| WC-10%Co-4%Cr | Высокое содержание хрома обеспечивает максимальную коррозионную стойкость. |

| WC-12%Co-3%Cr | Сочетает в себе прочность, износостойкость и коррозионную стойкость. |

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

| Вопрос | Ответить |

|---|---|

| Что такое твердосплавные изнашиваемые детали? | Компоненты изготовлены из карбида вольфрама, известного своей долговечностью и износостойкостью. |

| Почему стоит выбрать карбид вольфрама? | Он очень твердый, износостойкий и долговечный, что делает его идеальным для сложных условий эксплуатации. |

| Как долго служат износостойкие детали из твердого сплава? | Они служат значительно дольше, чем сталь или другие материалы, сокращая частоту замены. |

| Являются ли износостойкие детали из твердого сплава дорогими? | Они имеют более высокую первоначальную стоимость, но экономически выгодны в долгосрочной перспективе благодаря своей долговечности. |

| Можно ли ремонтировать детали из твердого сплава? | В некоторых случаях - да, но зачастую экономически выгоднее заменить их. |