Введение: Там, где царит точность

В сложном мире механической обработки, где тысячные доли дюйма могут сделать или разрушить функциональность детали, точность имеет первостепенное значение. Заходите на сайт . Тип F твёрдый сплав паяные наконечникиНевоспетые герои мира обработки, тщательно разработанные для обеспечения исключительной точности и чистоты поверхности при выполнении сложных операций чистовой и получистовой обработки.

Эта статья посвящена твердосплавным паяным наконечникам типа F, в ней рассматриваются их уникальные характеристики, преимущества и причины, по которым они являются наилучшим выбором, когда достижение жестких допусков и безупречных поверхностей не является обязательным условием.

Стремление к совершенству: Роль финишной и полуфинишной обработки

От грубого к изысканному: Этапы обработки

Операции механической обработки обычно включают в себя переход от черновой к чистовой обработке:

- Грубость: На начальном этапе основное внимание уделяется быстрому удалению большого количества материала для достижения приблизительной формы и размеров заготовки.

- Полуфиниш: Промежуточный этап, который преодолевает разрыв между черновой и чистовой обработкой, позволяя еще больше улучшить геометрию и качество поверхности заготовки.

- Отделка: Заключительный этап, направленный на достижение требуемой точности размеров, чистоты поверхности и общего качества готовой детали.

Твердосплавные паяные наконечники типа F отлично подходят для чистовой и получистовой обработки:

- Жесткие допуски: Соблюдение точности размеров в пределах тысячных долей дюйма имеет решающее значение для правильной подгонки, функционирования и сборки деталей.

- Превосходная отделка поверхности: Получение гладких, бездефектных поверхностей необходимо для обеспечения эстетической привлекательности, снижения трения и износа, а также повышения коррозионной стойкости.

Паяные наконечники из карбида типа F: Прецизионные наконечники, созданные для совершенства

Анатомия точности и точности поверхности

Твердосплавные паяные наконечники типа F тщательно разработаны для финишных и полуфинишных операций и характеризуются:

- Острые режущие кромки: Наконечники типа F, сочетающие положительные и отрицательные углы наклона, в первую очередь ориентированы на острые режущие кромки, что позволяет минимизировать силу резания и получить ровные, точные срезы, обеспечивающие исключительную чистоту поверхности.

- Малый радиус носа: Малый радиус носовой части наконечников типа F позволяет:

- Тонкие детали поверхности: Точная обработка тонких элементов и достижение малых радиусов на заготовке.

- Минимизация гребешков: Уменьшение видимых гребешков или выступов, которые могут возникать на контурных поверхностях, особенно при использовании инструментов большого диаметра.

- Мелкозернистый твердый сплав: В наконечниках типа F обычно используются мелкозернистые сорта карбида с высокой твердостью и износостойкостью. К ним относятся:

- Поддерживайте острые режущие кромки: Необходим для достижения постоянной точности и чистоты поверхности на протяжении всего процесса обработки.

- Минимизация износа режущей кромки: Снижение необходимости частой смены инструмента и обеспечение предсказуемых высококачественных результатов.

Преимущества твердосплавных паяных наконечников типа F при финишной и полуфинишной обработке

Стремление к точности и совершенству поверхности

Тщательно продуманная конструкция и свойства материала твердосплавных паяных наконечников типа F обеспечивают несколько ключевых преимуществ:

- Исключительная точность размеров: Их острые режущие кромки и мелкозернистый твердый сплав позволяют добиться жестких допусков, обеспечивая соответствие деталей строгим требованиям к размерам.

- Превосходная отделка поверхности: Сочетание острой геометрии резания, мелкозернистого карбида и минимальных усилий резания позволяет получать исключительно гладкие поверхности без дефектов.

- Увеличение срока службы инструмента при финишной обработке: Хотя наконечники типа F не подвергаются таким же сильным нагрузкам при резании, как наконечники для черновой обработки, они все же обладают износостойкими твердосплавными материалами, обеспечивающими длительный срок службы инструмента, особенно при чистовой обработке, где параметры резания обычно умеренные.

- Универсальность в прецизионной обработке: Наконечники типа F подходят для широкого спектра отделочных и полуотделочных операций, включая тонкое фрезерование, контурирование, профилирование и чистовое точение.

Области применения паяных наконечников из карбида типа F

Точность и качество поверхности имеют первостепенное значение

Твердосплавные паяные наконечники типа F отлично подходят для применения в тех случаях, когда достижение жестких допусков и превосходной чистоты поверхности является критически важным:

- Изготовление пресс-форм и штампов: Обработка сложных полостей, сердечников и отверстий для выталкивающих штифтов в пресс-формах и штампах, используемых для производства пластмассовых деталей, резиновых компонентов или металлических отливок.

- Аэрокосмическое производство: Производство критически важных компонентов с жесткими допусками и гладкими поверхностями, необходимых для обеспечения аэродинамических характеристик, топливной эффективности и целостности конструкции.

- Производство медицинского оборудования: Создание сложных элементов и гладких поверхностей на медицинских имплантатах, хирургических инструментах и других прецизионных медицинских устройствах, где биосовместимость и качество поверхности имеют решающее значение.

- Оптические компоненты: Обработка линз, зеркал и других оптических компонентов с очень жесткими допусками и гладкими поверхностями для обеспечения надлежащего пропускания и отражения света.

Выбор правильного паяного наконечника из твердого сплава типа F: Факторы, которые необходимо учитывать

Тонкая настройка выбора инструмента для прецизионной финишной обработки

Выбор оптимального наконечника с пайкой из твердого сплава типа F требует тщательной оценки:

- Материал заготовки: Твердость, абразивность и термические свойства материала являются решающими факторами при выборе подходящей марки твердого сплава и покрытия.

- Требования к чистоте поверхности: Желаемая шероховатость поверхности, часто задаваемая в терминах Ra (средняя шероховатость) или Rz (средняя шероховатость от пика до вала), является основным фактором при выборе наконечника.

- Требования к допускам: Требуемые допуски на размеры влияют на выбор геометрии наконечника и подготовку режущей кромки.

- Операция обработки: Конкретная операция чистовой или получистовой обработки, например, тонкое фрезерование, контурная обработка или чистовое точение, влияет на выбор геометрии и размера наконечника.

- Возможности станков: Жесткость и точность станка могут повлиять на достижимую чистоту поверхности и допуски.

Выбор паяного наконечника из твердого сплава типа F: Упрощенное руководство

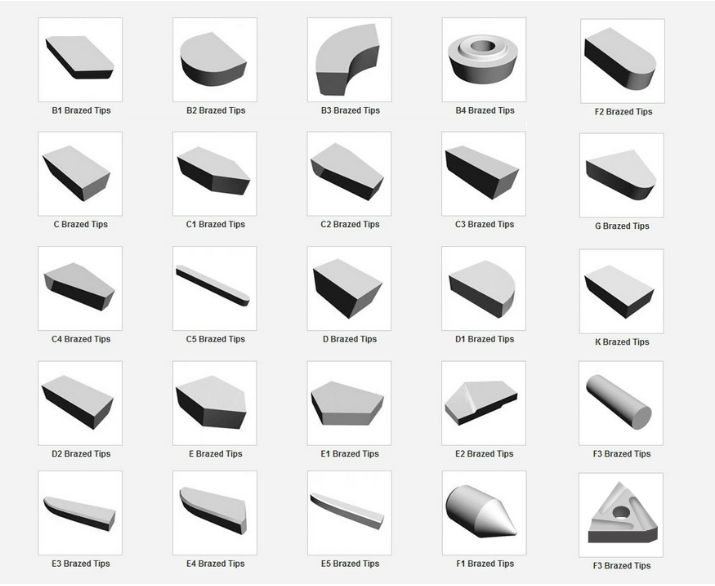

Чтобы помочь в процессе выбора, приводим таблицу с описанием типичных применений и соображений для различных геометрий наконечников типа F:

| Геометрия наконечника типа F | Типовые применения | Ключевые соображения |

|---|---|---|

| Круглая вставка с малым радиусом носа | Финишная обработка общего назначения, контурная обработка, профилирование | Обеспечивает хороший баланс остроты и прочности для широкого спектра применений |

| Квадратная вставка с острыми углами | Обработка плоских поверхностей, фрезерование уступов | Острые углы для точных 90-градусных плеч и плоских поверхностей |

| Алмазная вставка с острым острием | Гравировка, обработка мелких деталей, изготовление сложных пресс-форм | Обеспечивает исключительную резкость для самых тонких деталей и малых радиусов |

Часто задаваемые вопросы о паяных наконечниках из карбида типа F

Вопрос 1: Можно ли Твердосплавные паяные наконечники типа F использовать для черновой обработки?

A1: Наконечники типа F не предназначены для черновой обработки, и их использование в таких случаях не рекомендуется. Их острые режущие кромки и мелкозернистый карбид оптимизированы для чистовой и прецизионной обработки, а не для интенсивного съема материала.

Вопрос 2: Каковы признаки износа припаянного твердосплавного наконечника типа F?

A2: К общим признакам износа относятся закругление режущей кромки, износ граблины или боковой поверхности, а также образование нарастающей кромки (BUE) на режущей кромке. На операциях чистовой обработки износ может проявляться в ухудшении качества поверхности или потере точности размеров.

Вопрос 3: Как добиться наилучшего качества обработки поверхности с помощью припаянного твердосплавного наконечника типа F?

A3: Ключевыми факторами являются выбор подходящей геометрии и марки наконечника для конкретной задачи, оптимизация параметров резания (использование меньших подач и глубин резания), обеспечение правильного применения смазочно-охлаждающих жидкостей и поддержание жесткой настройки станка.

Вопрос 4: В чем разница между круглой и квадратной вставкой наконечника типа F?

A4: Круглые пластины с малым радиусом носовой части обеспечивают хороший баланс остроты и прочности для чистовой и контурной обработки общего назначения, а квадратные пластины с острыми углами идеально подходят для обработки плоских поверхностей и создания точных 90-градусных уступов.

Q5: Когда следует выбирать наконечник с алмазной вставкой типа F?

A5: Алмазные пластины с острыми концами обеспечивают исключительную остроту при гравировке, обработке мелких деталей и сложных форм, где достижение тончайших деталей и минимальных радиусов имеет первостепенное значение.