Робот для пресса

Робот используется в процессе прессования при производстве вкладышей, осуществляя автоматизацию процесса подбора вкладышей, удаления заусенцев, взвешивания и регулярного размещения. Он может эффективно и стабильно выполнять работу в соответствии с требованиями заказчика.

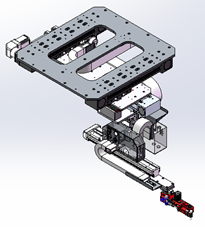

Расположение модуля движения:

Траектория движения каждой функциональной части тщательно продумана, а структура модулей разумно организована, так что общая компоновка отвечает самым высоким требованиям к эффективности и стабильности захвата.

Высокая жесткость рамы робота и мраморный противовес обеспечивают устойчивость робота во время высокоскоростного движения.

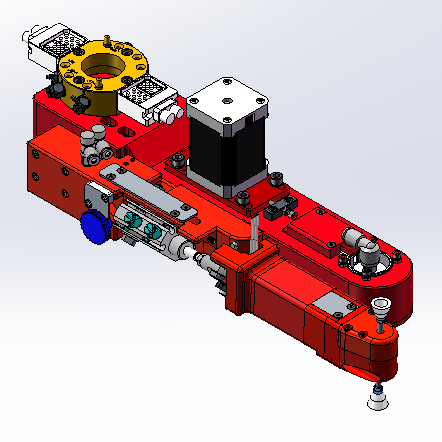

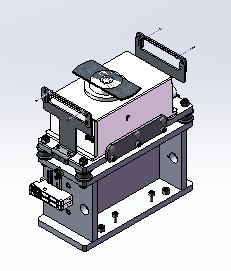

Захватный рычаг

Быстросменный механизм позволяет легко переключаться между оснасткой для отбора материала и очистительной оснасткой, что повышает стабильность производства пластин.

Применяется система быстросменной оснастки для быстрой смены роботизированного концевого инструмента.

Для осуществления вращения и изменения угла наклона вставки выбран шаговый двигатель.

Типы оснастки: Зажимные губки SMC, поддержка внутреннего отверстия, вакуумный отсос SMC, щетка для удаления остатков прилипшего порошка на пресс-форме и т.д.

Очистка пуансонов

Очищайте пуансон пресса различными способами, чтобы обеспечить его постоянное рабочее состояние.

Когда робот выполняет все функции, максимальная скорость прессования вкладышей может достигать 10 шт/мин.

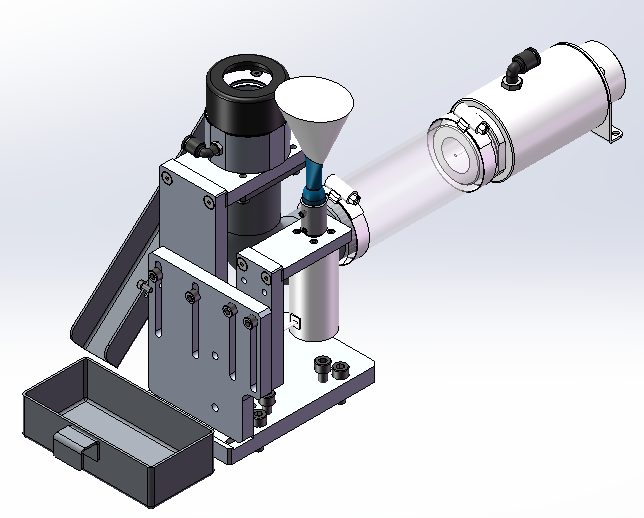

Удаление заусенцев

Щетка очищает заусенцы в нижней части вставки.

Очистите заусенцы с помощью воздушной струи в верхней части вставки.

Пылеулавливающий агрегат

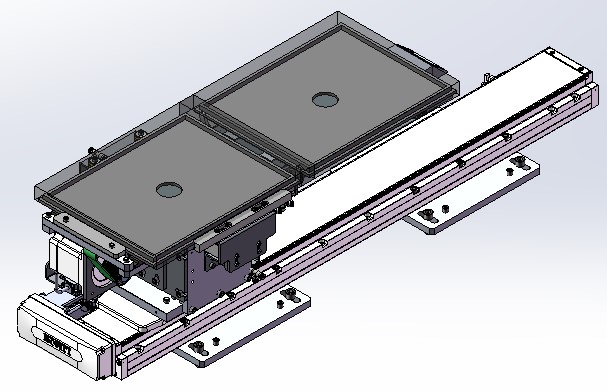

Баланс / Взвешивание

Используются сверхточные электронные весы японской фирмы AND или Ohaus с точностью +/-0,001 г. Вес каждого вкладыша может быть точно проверен, а изделия с неквалифицированным весом могут быть удалены по результатам измерений, при этом данные будут переданы на пресс. Пресс может регулировать параметры прессования в режиме реального времени для повышения стабильности производства.

Двойное равновесие является опцией для повышения эффективности производства.

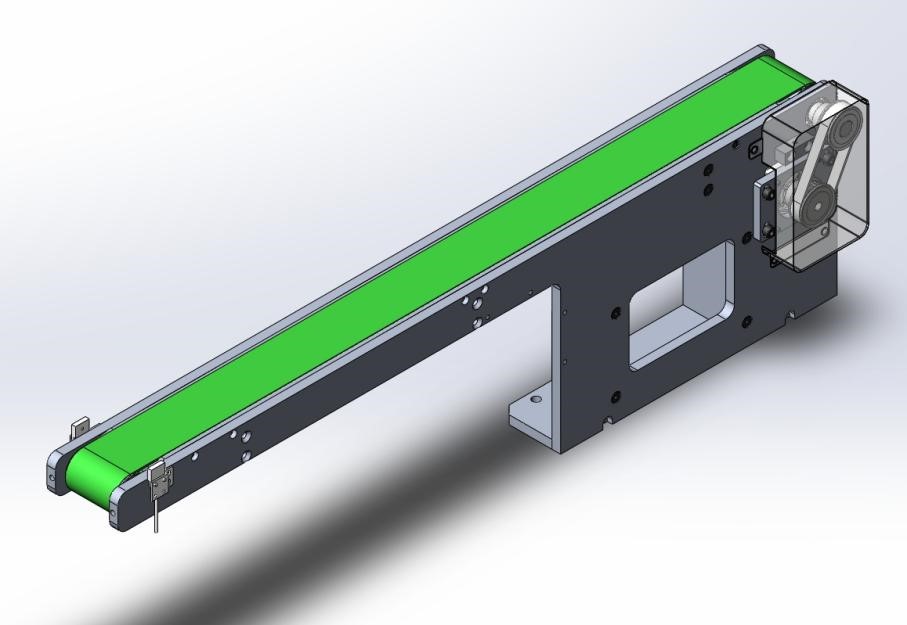

Конвейер для вставки образцов

Для транспортировки вставок с образцами используйте плоский ленточный конвейер.

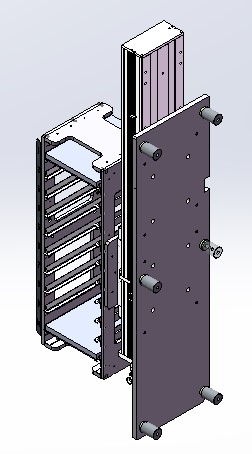

Лоток для спекания

Однослойный конвейер может отвечать требованиям безлюдного производства в массовом производстве.

Он оснащен 8-10 магазинами для лотков с материалами, что позволяет удовлетворить требования беспилотного производства в крупномасштабном производстве.

Транспортировочная графитовая лодка

Используются высокоскоростные и высокоточные модули, позволяющие точно реализовать последовательное размещение вставок и укладку графитовых лодок.

Графитовая лодка подается на позицию штабелирования плоским ленточным конвейером.

Для центрирования графитовой лодки используется пневматический цилиндр.

Модуль приводится в действие серводвигателем, а графитовая лодка подается ленточным конвейером, который приводится в действие шаговым двигателем.

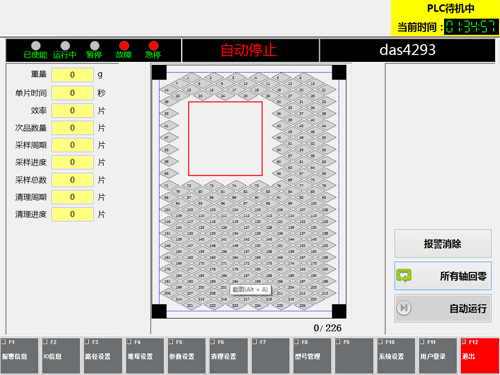

Простое управление

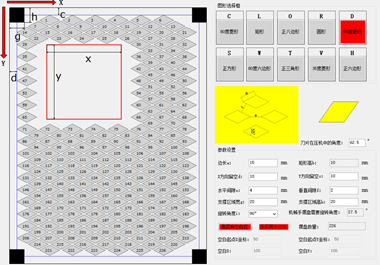

Обновление данных о размещении в режиме реального времени, цветовое (красное) заполнение размещенных вставок может быть выполнено в компьютерной системе в соответствии с фактическим ходом размещения, имитируя размещение на месте

Можно настроить и смоделировать параметры размещения популярных типов вставок. Итоговые параметры можно сохранить, чтобы в следующий раз легко использовать их при изготовлении подобных вставок.

Область на графитовой лодке, на которой не нужно размещать вставки, может быть разделена для использования в тестовых экспериментах.

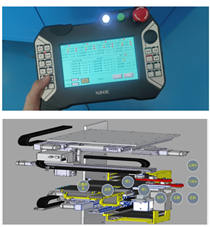

Перенастройка координат, когда необходимо перенастроить координаты, просто выберите соответствующую кнопку, остановите работу, когда робот переместится в новое положение. В это время с помощью обучающего кулона можно выполнить тонкую настройку движения робота и сохранить необходимые значения координат.

Приложение

Робот TRUER полностью совместим со следующими прессами!