Обзор

Когда речь идет о прецизионной обработке, выбор правильных инструментов может иметь огромное значение. Одним из таких важнейших инструментов является твердосплавная вставка с PVD-покрытием. Эти вставки играют ключевую роль в повышении эффективности, точности и долговечности процессов обработки. Но что делает их такими особенными? Как они сравниваются с другими вариантами? И как выбрать лучшую вставку для ваших конкретных нужд? В этом подробном руководстве мы расскажем обо всем, что вам нужно знать о Твердосплавные вставки с PVD-покрытиемОт их состава и свойств до применения и критериев выбора.

Что такое твердосплавные вставки с PVD-покрытием?

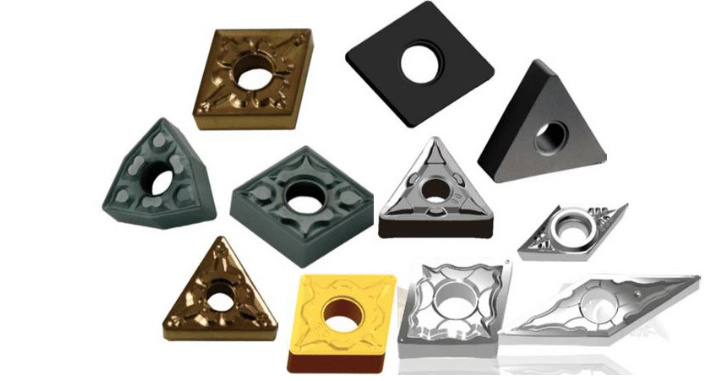

Твердосплавные пластины с покрытием PVD (Physical Vapor Deposition) - это режущий инструмент, используемый в различных операциях обработки. Процесс PVD включает в себя осаждение тонких твердых покрытий на твердосплавные подложки. Такое покрытие повышает эксплуатационные характеристики пластин, обеспечивая превосходную твердость, износостойкость и жаропрочность, тем самым продлевая срок службы инструмента и улучшая качество обрабатываемого изделия.

Основные характеристики твердосплавных вставок с PVD-покрытием

- Повышенная твердость: PVD-покрытие значительно повышает твердость поверхности твердосплавной вставки, делая ее более устойчивой к износу и деформации.

- Повышенная износостойкость: Покрытие снижает скорость износа вставки, обеспечивая стабильную работу в течение длительного времени.

- Улучшенная термостойкость: PVD-покрытия выдерживают высокие температуры, что делает эти пластины идеальными для высокоскоростной обработки.

- Уменьшенное трение: Гладкое, твердое покрытие уменьшает трение между пластиной и заготовкой, улучшая качество обрабатываемой поверхности.

Типы твердосплавных вставок с PVD-покрытием

| Модель | Описание |

|---|---|

| TNMG 160404-PF | Вставка общего назначения для стали, нержавеющей стали и чугуна с превосходной износостойкостью и долговечностью. |

| CNMG 120408-MF | Идеально подходит для чистовой и получистовой обработки стали и нержавеющей стали, обеспечивая высокую точность и качество поверхности. |

| DNMG 150608-PF | Подходит для высокоскоростного точения стали и чугуна, обеспечивая превосходный контроль стружки и износостойкость. |

| WNMG 080404-MF | Универсальная вставка для широкого спектра материалов, включая сталь, нержавеющую сталь и высокотемпературные сплавы. |

| SNMG 120408-QM | Предназначен для черновой и чистовой обработки нержавеющей стали и стали, обеспечивая высокую производительность и срок службы инструмента. |

| VNMG 160404-MF | Прецизионная пластина для тонкой обработки стали и нержавеющей стали, обеспечивающая превосходную чистоту и точность поверхности. |

| CCMT 09T304-PF | Идеально подходит для обработки мелких деталей, обеспечивая превосходную стойкость кромок и износостойкость. |

| DCMT 11T304-MF | Идеально подходит для высокоточной токарной обработки небольших деталей, обеспечивая превосходный контроль стружки и качество обработки поверхности. |

| SCMT 09T304-PF | Предназначен для среднего и грубого точения стали и нержавеющей стали, обеспечивает длительный срок службы и стабильность инструмента. |

| RCMT 10T3MO | Используется для черновой и получистовой обработки чугуна и цветных металлов, обладает высокой износостойкостью. |

Применение Твердосплавные вставки с PVD-покрытием

| Приложение | Описание |

|---|---|

| Обработка стали | Идеально подходит для высокоскоростной и прецизионной обработки различных марок стали. |

| Обработка нержавеющей стали | Обеспечивает превосходную производительность при обработке нержавеющей стали, снижая износ и увеличивая срок службы инструмента. |

| Обработка чугуна | Подходит для черновой и чистовой обработки чугуна, обеспечивая высокую прочность и износостойкость. |

| Обработка цветных металлов | Отлично подходит для обработки алюминия, меди и других цветных металлов с минимальным износом инструмента. |

| Высокотемпературные сплавы | Идеально подходит для обработки сверхпрочных сплавов, титана и других высокотемпературных материалов. |

Свойства материала

| Недвижимость | Описание |

|---|---|

| Твердость | Повышенная твердость поверхности благодаря PVD-покрытию, обычно выше 2000 HV. |

| Жесткость | Сохраняет вязкость твердосплавной основы, обеспечивая устойчивость к сколам и разрушению. |

| Износостойкость | Повышенная износостойкость по сравнению с пластинами без покрытия или с обычным покрытием. |

| Термостойкость | Способны выдерживать высокие температуры, что делает их пригодными для высокоскоростной обработки. |

Состав, свойства и характеристики

| Компонент | Свойства | Характеристики |

|---|---|---|

| Твердосплавная подложка | Высокая прочность и твердость, обеспечивающие прочную основу для нанесения PVD-покрытия. | Обеспечивает долговечность и устойчивость к механическим воздействиям. |

| PVD-покрытие | Тонкий, твердый слой материалов, таких как TiN, TiAlN или AlCrN, обеспечивающий превосходную износостойкость. | Снижает трение, повышает износостойкость и теплостойкость. |

| Фаза переплета | Обычно это кобальт или никель, который связывает зерна карбида вместе. | Сохраняет прочность и структурную целостность вставки. |

Твердость, прочность и износостойкость

| Параметр | Описание |

|---|---|

| Твердость (HV) | Обычно составляет от 2000 до 3000 HV, в зависимости от материала покрытия. |

| Прочность на изгиб | Высокая прочность на изгиб, благодаря чему вставка выдерживает механические нагрузки при обработке. |

| Износостойкость | Превосходная износостойкость, значительно увеличивающая срок службы инструмента по сравнению с пластинами без покрытия. |

Технические характеристики, размеры, форма и стандарты

| Спецификация | Описание |

|---|---|

| Стандарты ISO | Вставки соответствуют стандартам ISO, обеспечивая совместимость и производительность. |

| Размеры | Поставляются различных размеров для удовлетворения различных потребностей в обработке и держателей инструментов. |

| Формы | К распространенным формам относятся треугольник, квадрат, ромб, круг и параллелограмм. |

Поставщики и ценовая политика

| Поставщик | Ассортимент продукции | Диапазон цен |

|---|---|---|

| Sandvik Coromant | Широкий ассортимент твердосплавных вставок с PVD-покрытием для различных областей применения. | $10 - $50 за вставку, в зависимости от спецификации. |

| Kennametal | Высокопроизводительные вставки с усовершенствованными PVD-покрытиями для различных материалов. | $12 - $55 за вставку, в зависимости от спецификации. |

| Инструменты Seco | Широкий выбор пластин с оптимизированным PVD-покрытием для различных задач обработки. | $11 - $48 за вставку, в зависимости от спецификации. |

| Mitsubishi Materials | Инновационные вставки с превосходным PVD-покрытием для повышения производительности. | $13 - $60 за вставку, в зависимости от спецификации. |

| Kyocera | Универсальные пластины с PVD-покрытием для широкого спектра материалов и применений. | $9 - $45 за вставку, в зависимости от спецификации. |

Как правильно выбрать твердосплавные вставки с PVD-покрытием

| Рассмотрение | Описание |

|---|---|

| Обрабатываемый материал | Выбирайте вставки в зависимости от материала, который вы обрабатываете (например, сталь, нержавеющая сталь, чугун). |

| Операция обработки | Определите, какие пластины вам нужны для черновой, чистовой или получистовой обработки. |

| Скорость резки | Выбирайте пластины, способные выдерживать скорость резания, необходимую для вашей задачи. |

| Совместимость с держателями инструментов | Убедитесь, что пластины совместимы с имеющимися у вас держателями инструментов и оборудованием. |

| Стоимость и бюджет | Учитывайте экономическую эффективность вставок, балансируя между производительностью и бюджетными ограничениями. |

Преимущества и ограничения твердосплавных вставок с PVD-покрытием

| Аспект | Преимущества | Ограничения |

|---|---|---|

| Долговечность | Значительно больший срок службы инструмента по сравнению с пластинами без покрытия. | Первоначальная стоимость может быть выше, чем у вставок без покрытия или с обычным покрытием. |

| Производительность | Превосходная производительность при высокоскоростной и прецизионной обработке. | Для оптимальной работы могут потребоваться специальные держатели инструментов или оборудование. |

| Стоимость | Экономичность с течением времени благодаря сокращению времени замены инструмента и простоев. | Более высокая первоначальная стоимость. |

| Универсальность | Подходит для широкого спектра материалов и операций обработки. | Не все PVD-покрытия подходят для всех материалов; для конкретных применений требуются особые покрытия. |

Вопросы и ответы

| Вопрос | Ответить |

|---|---|

| В чем главное преимущество твердосплавных пластин с PVD-покрытием? | Они обладают повышенной твердостью, износостойкостью и жаропрочностью, что позволяет продлить срок службы инструмента. |

| Можно ли использовать вставки с PVD-покрытием для всех материалов? | Несмотря на свою универсальность, конкретные покрытия оптимизированы для определенных материалов, таких как сталь, нержавеющая сталь или чугун. |

| Как выбрать подходящую вставку для моего применения? | Учитывайте такие факторы, как обрабатываемый материал, тип операции, скорость резания и совместимость с держателем инструмента. |

| Являются ли вставки с PVD-покрытием более дорогими, чем вставки без покрытия? | Они имеют более высокую первоначальную стоимость, но со временем становятся более рентабельными за счет снижения износа и увеличения срока службы инструмента. |

| Могут ли пластины с PVD-покрытием улучшить качество обработки? | Да, они уменьшают трение и износ, что приводит к улучшению качества обработки поверхности и точности размеров. |

Заключение

Выбор правильного Твердосплавные вставки с PVD-покрытием могут существенно повлиять на эффективность, качество и рентабельность ваших операций по обработке. Понимая различные типы, области применения и свойства этих вставок, вы сможете принять обоснованное решение, которое улучшит ваши производственные процессы. Независимо от того, обрабатываете ли вы сталь, нержавеющую сталь, чугун или цветные металлы, найдется вставка с PVD-покрытием, которая удовлетворит ваши потребности и превзойдет ваши ожидания.