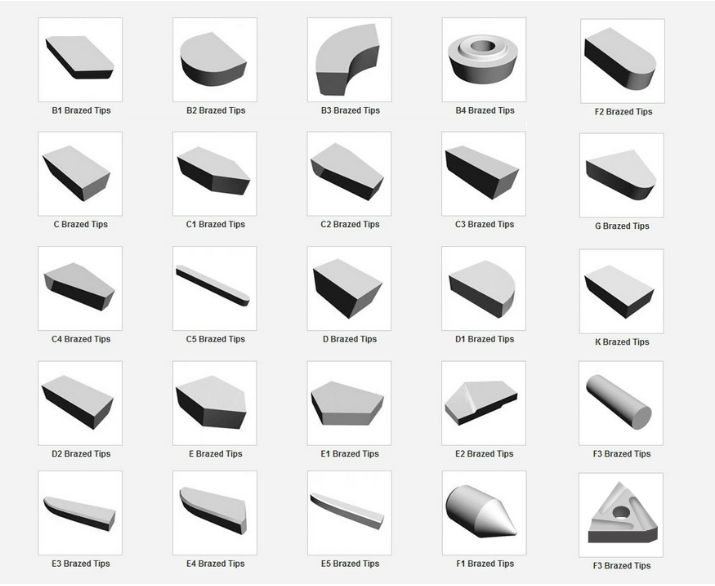

Паяные наконечники из твердого сплава типа B для безостановочного фрезерования

А теперь представьте себе режущий инструмент, который лежит в основе этой операции, - паяные наконечники из твердого сплава типа B, разработанные для того, чтобы выдерживать огромные усилия и прерывистые режимы резания, характерные для фрезерования.