When it comes to industrial tooling and machining applications, твёрдосплавные стержни are indispensable. Their pricing, however, can seem like a maze of complexity. From the raw materials to the manufacturing process, several factors influence the cost. If you’re diving into the world of carbide rods, you’re in the right place. Let’s break this down and explore everything about carbide rod pricing, including specifications, applications, and how to make the best choice for your needs.

Understanding Carbide Rods and Their Applications

Что такое твердосплавные стержни?

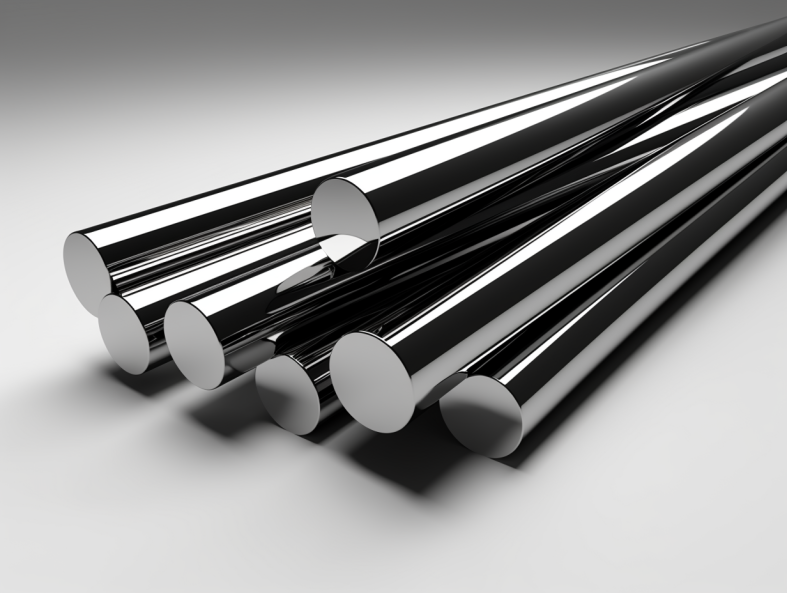

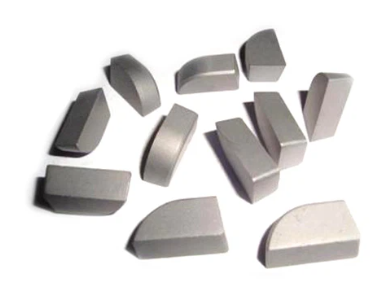

Carbide rods are cylindrical tools made from порошок карбида вольфрама mixed with a binder like cobalt. These materials are sintered under high heat and pressure, creating a hard, durable product with excellent wear resistance. You’ll find carbide rods in industries like aerospace, automotive, and manufacturing for tasks like drilling, cutting, and milling.

Key Factors Influencing Цены на твердосплавные стержни

Raw Material Composition

The composition of carbide rods plays a significant role in their pricing. Tungsten carbide, the main component, is a rare and expensive material. Adding cobalt, titanium carbide, or other binders increases the cost further.

| Материал | Composition (%) | Cost Contribution |

|---|---|---|

| Карбид вольфрама | 85-95 | Высокая |

| Cobalt (Binder) | 5-10 | Средний |

| Карбид титана | 1-3 | Низкий |

Технологический процесс

The production process is another major cost driver. Here’s a simplified breakdown:

- Подготовка порошка: Raw tungsten carbide is mixed with cobalt.

- Нажатие кнопки: The mixture is compacted into a rod shape.

- Агломерация: High-temperature sintering creates a dense, strong material.

- Отделка: Polishing and coating the rod enhance its performance.

Each of these steps requires precision and specialized equipment, adding to the final cost.

Carbide Rod Applications and Cost Dynamics

Carbide rods are used in several industries, each with unique pricing demands:

| Приложение | Specific Use | Pricing Impact |

|---|---|---|

| Аэрокосмическая промышленность | Cutting and drilling aircraft components | High (due to quality demands) |

| Автомобильная промышленность | Обработка деталей двигателя | Средний |

| Производство | General-purpose tooling | Low to medium |

| Электроника | Precision drilling in PCB production | От среднего до высокого |

Metal Powder Models and Their Impact on Pricing

Different grades of metal powders affect carbide rod performance and cost. Here’s a look at ten common models:

| Модель порошка | Состав | Характеристики | Приложения | Диапазон цен |

|---|---|---|---|---|

| WC-10Co | 90% WC, 10% Co | Высокая прочность | Milling cutters, drills | $$$ |

| WC-12Co | 88% WC, 12% Co | Отличная износостойкость | Горные инструменты | $$$$ |

| WC-15Co | 85% WC, 15% Co | Superior strength | Инструменты для тяжелых условий эксплуатации | $$$$ |

| WC-TiC | WC with TiC | Устойчивость к высоким температурам | Aerospace tools | $$$$$ |

| Submicron WC | Ultra-fine WC | Чрезвычайная твердость | Прецизионные инструменты | $$$$$ |

| Nano WC | Nano WC | Best wear resistance | Электроника | $$$$$ |

| WC-Co-Cr | WC with Co, Cr | Anti-corrosion | Marine tools | $$$$ |

| WC-Co-TaC | WC with Co, TaC | Превосходная термическая стабильность | Автомобильная промышленность | $$$$ |

| WC-Co-Al2O3 | WC with Co, Al2O3 | Improved oxidation resistance | Cutting applications | $$$ |

| WC-Ni | WC with Ni | Enhanced toughness and ductility | Custom tools | $$$$ |

Свойства материала твердосплавных стержней

The quality of carbide rods is evaluated based on properties like hardness, strength, and wear resistance.

| Недвижимость | Диапазон | Значение |

|---|---|---|

| Твердость (HRA) | 85-92 | Determines cutting ability |

| Поперечная прочность | 2000-4000 MPa | Measures toughness |

| Износостойкость | Высокая | Ensures long tool life |

| Плотность | 14,0-15,5 г/см³ | Affects weight and usability |

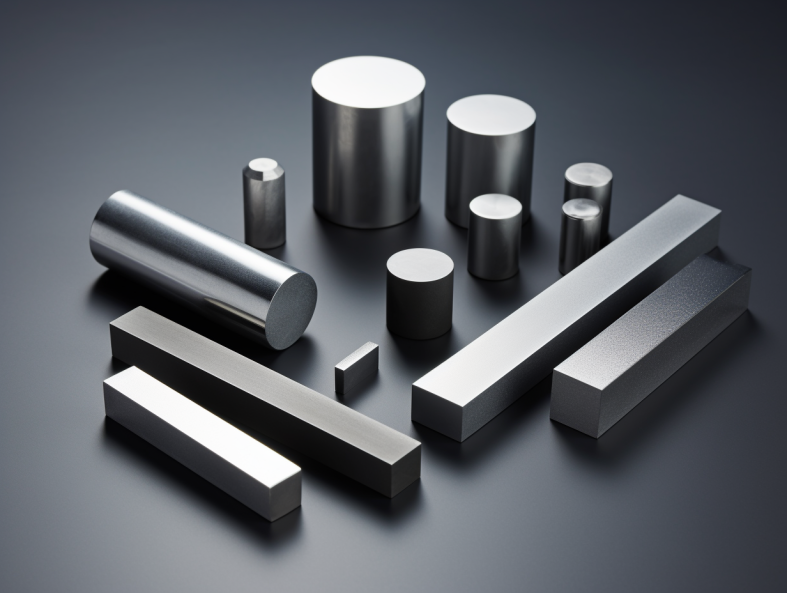

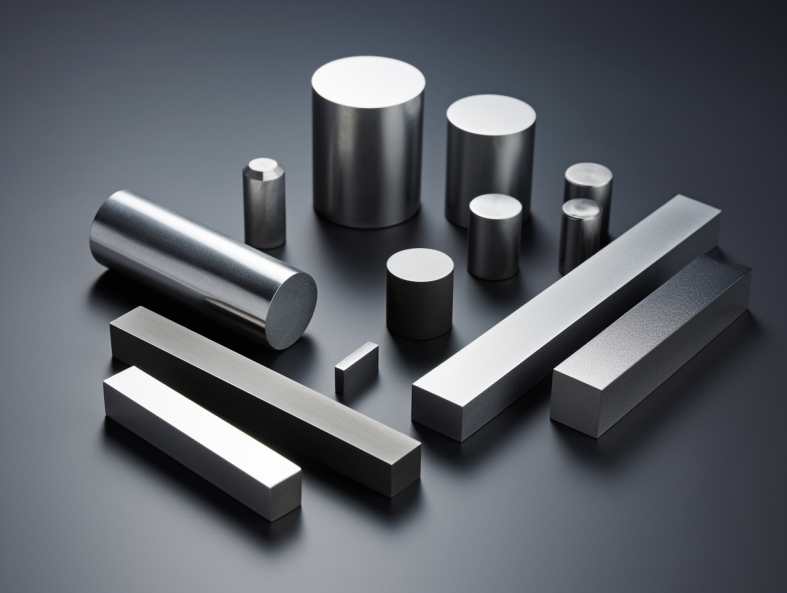

Технические характеристики, размеры, формы и стандарты

Carbide rods come in a wide range of specifications to suit different applications.

| Спецификация | Подробности |

|---|---|

| Длина | 50-330 мм |

| Диаметр | 3-40 mm |

| Форма | Round, rectangular, square |

| Стандарты | ISO, ASTM, GB |

Поставщики и ценовая политика

Finding reliable suppliers ensures cost-effective carbide rod procurement.

| Поставщик | Диапазон цен (за кг) | Delivery Options |

|---|---|---|

| Sandvik | $50-$150 | Worldwide |

| Kennametal | $60-$180 | Bulk discounts |

| Цементированный карбид из Чжучжоу | $40-$120 | Персонализация |

Преимущества и ограничения твердосплавных стержней

| Преимущества | Ограничения |

|---|---|

| Исключительная твердость | Expensive raw materials |

| Высокая износостойкость | Сложность обработки |

| Превосходная термическая стабильность | Ограниченная гибкость |

Selecting the Right Carbide Rod

When choosing carbide rods, consider these factors:

| Критерии | Ключевые соображения |

|---|---|

| Тип приложения | Aerospace, manufacturing, etc. |

| Состав материала | High WC content for durability |

| Диапазон цен | Баланс между стоимостью и производительностью |

Вопросы и ответы

| Вопрос | Ответить |

|---|---|

| Почему твердосплавные стержни стоят дорого? | Due to costly raw materials and precision manufacturing |

| Which industries use carbide rods most? | Aerospace, automotive, electronics, manufacturing |

| How do I choose the best carbide rod supplier? | Consider pricing, quality standards, and delivery options |

| Can I customize carbide rod specifications? | Yes, many suppliers offer tailored solutions |

By understanding these factors and comparing options effectively, you’ll be better equipped to navigate the market for carbide rods. Ready to invest in high-quality carbide rods for your next project.