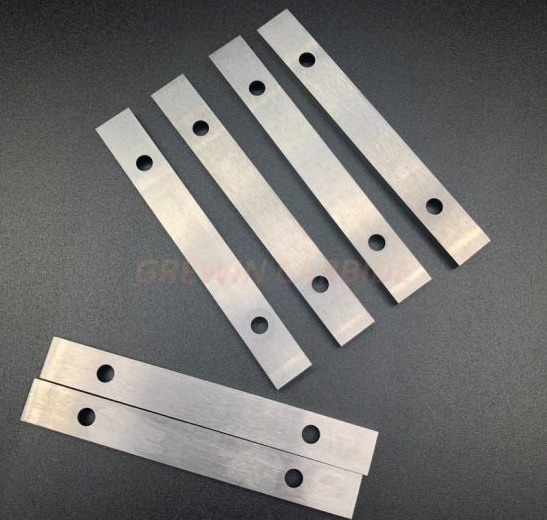

Wear and tear are inevitable in industries dealing with heavy machinery, mining, and manufacturing. Твердосплавные пластины for wear liners offer an exceptional solution to prolong equipment life and enhance efficiency.

Characteristics of Carbide Plates for Wear Liners

Твердосплавные пластины, primarily made from tungsten carbide (WC) or chromium carbide (CrC), are designed to withstand extreme wear conditions. Here’s what makes them exceptional:

- Чрезвычайная твердость: With a Mohs hardness rating of 9+, tungsten carbide plates are nearly as hard as diamonds.

- Высокая износостойкость: These plates can endure abrasive materials like sand, ore, and coal far longer than steel.

- Коррозионная стойкость: Unlike standard steel, carbide plates resist oxidation and chemical exposure, making them ideal for harsh environments.

- Impact Toughness: Some carbide compositions offer increased impact resistance, reducing breakage risks.

- Customizable Composition: Depending on the application, carbide plates can be mixed with different metal powders to enhance specific properties.

Top 10 Metal Powder Models for Carbide Plates

To optimize performance, carbide plates incorporate various metal powders. Here are 10 top-rated metal powders used in carbide plates:

| Модель металлического порошка | Состав | Лучшее для |

|---|---|---|

| WC-Co | Карбид вольфрама + кобальт | Горная промышленность, бурение |

| Cr3C2-NiCr | Chromium Carbide + Nickel Chromium | Высокотемпературные применения |

| TiC | Карбид титана | Cutting tools, high-speed machining |

| Mo2C | Карбид молибдена | Aerospace, extreme wear resistance |

| NbC | Карбид ниобия | Steel industry, heat shielding |

| ВК | Карбид ванадия | High-strength tools |

| ZrC | Карбид циркония | Nuclear, extreme heat resistance |

| TaC | Карбид тантала | Aerospace, advanced electronics |

| WC-Ni | Карбид вольфрама + никель | Oil drilling, wear-resistant coatings |

| B4C | карбид бора | Bulletproof applications, lightweight armor |

Common Application Industries of Carbide Plates for Wear Liners

Carbide wear liners play a crucial role in various industries where durability and longevity are vital. Here are some industries that benefit most from carbide plates:

1. Mining & Quarrying

- Используется в chute liners, hoppers, and conveyor belts to withstand rock abrasion.

- Extends the lifespan of crushers and grinding mills.

2. Oil & Gas Drilling

- Необходим для drill bits and wear-resistant coatings on extraction machinery.

- Reduces downtime due to premature wear.

3. Construction & Earthmoving

- Excavator bucket liners, bulldozer blades, and wear plates benefit from carbide plates.

- Enhances resistance to harsh terrain and impact loads.

4. Steel & Metal Manufacturing

- Protects furnace walls, ladle linings, and rolling mills.

- Minimizes heat and corrosion damage in extreme conditions.

5. Agriculture & Forestry

- Используется в plowshares, harvesting equipment, and saw blades.

- Prevents wear from soil, gravel, and vegetation.

How to Choose the Appropriate Carbide Plates for Wear Liners

Выбор правильного твёрдосплавные пластины depends on various factors. Here’s what to consider:

- Состав материала – WC-Co for mining, Cr3C2-NiCr for high temperatures, etc.

- Твердость против жесткости – Higher hardness for abrasion resistance, but increased toughness for impact resistance.

- Среда применения – Corrosion resistance needed? High heat? Heavy impact loads?

- Thickness & Size – Thicker plates last longer but may be heavier and costlier.

- Cost vs. Longevity – Higher initial investment often means lower long-term replacement costs.

Carbide Plates vs. Other Wear-Resistant Materials

| Недвижимость | Пластины из карбида вольфрама | Chromium Carbide Plates | Закаленная сталь | Керамика |

|---|---|---|---|---|

| Твердость | Extreme (9+ Mohs) | High (6-7 Mohs) | Moderate (4-6 Mohs) | Very High (9-10 Mohs) |

| Износостойкость | Superior | Отличный | Хороший | Superior |

| Impact Toughness | Умеренный | Высокая | Высокая | Низкий |

| Коррозионная стойкость | Высокая | Очень высокий | Низкий | Высокая |

| Термостойкость | Высокая | Очень высокий | Умеренный | Высокая |

| Стоимость | Высокая | Средний | Низкий | Высокая |

How to Install and Maintain Твердосплавные пластины for Wear Liners

Installation Techniques

- Welding: Best for high-load applications but requires precision to prevent cracking.

- Bolting: Allows easy replacement but may not be as secure as welding.

- Клеевое соединение: Used in lower-impact areas where welding isn’t feasible.

Maintenance Tips

- Regular Inspections: Check for cracks, wear patterns, and corrosion.

- Cleaning Procedures: Use non-abrasive cleaners to avoid surface damage.

- Timely Replacements: Replace sections before complete failure to prevent machine downtime.

Вопросы и ответы

| Вопрос | Ответить |

|---|---|

| What is the lifespan of carbide wear liners? | It varies by application but typically lasts В 3-10 раз дольше than steel liners. |

| Дорогие ли твердосплавные пластины? | They have a higher upfront cost but reduce replacement frequency, making them cost-effective in the long run. |

| Can carbide liners be customized? | Yes! They can be cut, shaped, and alloyed to fit specific industrial needs. |

| How do I know if I need tungsten or chromium carbide? | Карбид вольфрама is best for abrasion resistance, while карбид хрома excels in high-temperature environments. |

| Are carbide plates environmentally friendly? | Yes, they reduce material waste and are often recyclable. |