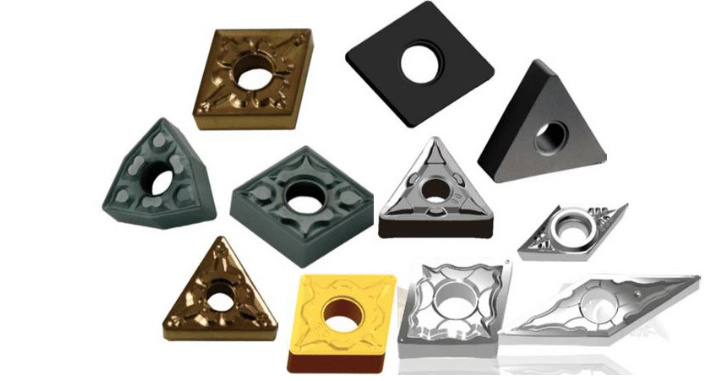

Что такое Твердосплавная пластина?

Твердосплавные пластины - это высокопроизводительные металлические компоненты, изготовленные в основном из карбида вольфрама (WC), часто соединенного с кобальтом (Co) или другими связующими для улучшения механических свойств. Эти пластины широко используются в промышленности, где требуется высокая износо- и коррозионная стойкость.

Факторы, влияющие на коррозионную стойкость

Твердосплавные пластины прочны, но их коррозионная стойкость зависит от множества факторов. Давайте разберемся в них:

1. Состав связующего

Выбор связующего вещества играет решающую роль в коррозионной стойкости. Например:

- Кобальт (Co): Повышает прочность, но более подвержен коррозии в кислой среде.

- Никель (Ni): Обладает лучшей коррозионной стойкостью, чем кобальт, особенно в морских условиях и при химической обработке.

- Добавки хрома (Cr): Повышает устойчивость к окислению и воздействию кислот.

2. Размер зерна карбидного порошка

Более мелкие зерна карбида обеспечивают большую плотность и меньшую пористость, что делает материал менее подверженным коррозии. Крупные зерна могут создавать слабые места, через которые могут проникать коррозионные агенты.

3. Экологические факторы

Воздействие экстремальных условий, таких как высокая влажность, кислотные растворы или соленая вода, может ускорить коррозию. Понимание условий работы помогает выбрать правильный состав твердого сплава.

4. Обработка поверхности и покрытия

Нанесение защитного покрытия, такого как TiN (нитрид титана) или Al2O3 (оксид алюминия), может значительно повысить устойчивость к коррозии.

Преимущества Твердосплавные пластины в коррозионных средах

Почему промышленные предприятия должны выбирать твердосплавные пластины вместо обычных металлов? Вот несколько неоспоримых преимуществ:

- Превосходная твердость и прочность: В отличие от нержавеющей стали, твердосплавные пластины сохраняют свою целостность даже при экстремальных нагрузках и перепадах температур.

- Увеличенный срок службы: Высокая устойчивость к износу и коррозии снижает затраты на замену и время простоя.

- Химическая устойчивость: Идеально подходит для применения в жестких условиях химической обработки, где другие металлы могут быстро разрушаться.

- Допуск к высоким температурам: Карбид остается структурно прочным при температурах, при которых сталь и алюминий могут ослабнуть.

Области применения коррозионно-стойких твердосплавных пластин

| Промышленность | Приложение | Коррозионное воздействие |

|---|---|---|

| Нефть и газ | Буровые инструменты, клапаны, уплотнения насосов | Морская вода, сырая нефть |

| Химическая обработка | Теплообменники, футеровка реакторов | Кислотные и щелочные химикаты |

| Аэрокосмическая промышленность | Компоненты двигателя, форсунки высокого давления | Экстремальные температуры, влажность |

| Морской | Пропеллерные валы, компоненты судов | Коррозия в соленой воде |

| Добыча | Износостойкие конвейерные пластины | Влага, абразивные вещества |

Как повысить коррозионную стойкость Твердосплавные пластины?

| Метод | Описание | Эффективность |

|---|---|---|

| Оптимизация связующего | Использование связующих на основе Ni или Cr вместо Co | Высокая |

| Нанозернистая структура | Более мелкие зерна твердого сплава уменьшают пористость | Высокая |

| Поверхностные покрытия | TiN, Al2O3 или PVD-покрытия для защиты | Очень высокий |

| Химическая обработка | Методы пассивации для повышения стабильности поверхности | Умеренный |

| Дополнения к сплаву | Включение таких элементов, как ванадий или хром | Высокая |

Характеристики коррозионной стойкости и область применения твердосплавных пластин

Твердосплавные пластины неоценимы в отраслях, требующих особой прочности. При правильном выборе состава материала и защитных мер их коррозионная стойкость может соответствовать или даже превосходить стойкость традиционной нержавеющей стали. По сравнению с такими альтернативами, как высоколегированные стали, твердосплавные пластины обладают превосходной долговечностью, экономичностью и производительностью в агрессивных средах.

Топ 10 лучших моделей порошков карбида с коррозионной стойкостью

| Модель карбидного порошка | Состав | Лучшее для применения |

|---|---|---|

| WC-Co (6%) | Карбид вольфрама, кобальт 6% | Режущие инструменты, быстроизнашивающиеся детали |

| WC-Ni (8%) | Карбид вольфрама, никель 8% | Химическая переработка, морские перевозки |

| WC-CrC-Ni | Карбид вольфрама, карбид хрома, никель | Аэрокосмическая промышленность, высокотемпературные среды |

| TiC-WC-Co | Карбид титана, карбид вольфрама, кобальт | Высокоскоростная обработка |

| WC-Co-Cr | Карбид вольфрама, кобальт, хром | Коррозионно-стойкие покрытия |

| WC-NiMoCr | Карбид вольфрама, никель, молибден, хром | Нефтегазовая промышленность |

| WC-Co-V | Карбид вольфрама, кобальт, ванадий | Абразивные среды |

| WC-FeNi | Карбид вольфрама, железо, никель | Сверхмощные промышленные приложения |

| WC-Cr3C2 | Карбид вольфрама, карбид хрома | Исключительная износостойкость |

| WC-Al2O3 | Карбид вольфрама, оксид алюминия | Высокая термостойкость |

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

| Вопрос | Ответить |

|---|---|

| Являются ли твердосплавные пластины полностью защищенными от коррозии? | Нет, но они обладают высокой прочностью в зависимости от используемого связующего и покрытия. |

| Как выбрать лучшую твердосплавную пластину для моего применения? | Учитывайте такие факторы, как окружающая среда, температура и химическое воздействие. Для обеспечения коррозионной стойкости лучше всего подходят связующие на основе никеля. |

| Можно ли использовать твердосплавные пластины в морской воде? | Да, особенно с никелевыми связующими и защитными покрытиями, такими как CrC. |

| Какие покрытия могут повысить коррозионную стойкость твердого сплава? | Покрытия TiN, Al2O3 и PVD обеспечивают превосходную защиту. |

| Как твердосплавные пластины соотносятся с нержавеющей сталью? | Твердый сплав более твердый и износостойкий, но в некоторых случаях нержавеющая сталь может быть предпочтительнее из-за более низкой стоимости и большей гибкости. |