Наконечники с твердосплавной пайкой являются краеугольным камнем в современных промышленных приложениях, обеспечивая исключительную производительность в процессах резки, сверления и обработки. Если вы когда-нибудь задумывались о том, как эти крошечные, но могущественные компоненты появляются на свет, о сферах их применения или о том, как выбрать лучшие из них, вы попали по адресу. Давайте разберемся в этом в увлекательной и подробной форме, без скучного жаргона!

Что такое наконечник с твердосплавной напайкой?

Представьте себе инструмент с острыми краями, способный прорезать самые прочные металлы, как горячий нож масло. Именно это и делает припаянный твердосплавный наконечник! Это режущая пластина из карбида, соединенная с корпусом инструмента при помощи пайки. Эти наконечники популярны благодаря своей непревзойденной твердости, износостойкости и способности работать в условиях сильного нагрева.

Типы Наконечники с твердосплавной напайкой

Здесь представлена таблица с различными типами твердосплавных паяных наконечников и их характеристиками:

| Тип | Основное использование | Типичные материалы | Основные характеристики |

|---|---|---|---|

| Общие советы по резке | Резка металла и дерева | Карбид вольфрама | Высокая прочность, многоцелевое назначение |

| Советы по токарной обработке | Токарные станки и станки с ЧПУ | Сплавы кобальта и никеля | Превосходная термостойкость |

| Советы по бурению | Высокоточное сверление | Композит из карбида титана | Точная и плавная работа |

| Советы по фрезерованию | Фрезерные работы в тяжелых условиях | Смеси карбида хрома | Долгий срок службы при высоких нагрузках |

| Советы по обработке канавок | Прецизионное фрезерование | Карбид вольфрама-титана | Улучшенный контроль и точность чипов |

| Советы по планированию | Строгание металлических поверхностей | Мелкозернистый карбид вольфрама | Отличная обработка поверхности |

| Скучные советы | Глубокое бурение | Субмикронный карбид вольфрама | Исключительная жесткость и прочность |

| Советы по нарезанию резьбы | Нарезание резьбы на материалах | Карбид на никелевой связке | Постоянный профиль резьбы |

| Износостойкие наконечники | Инструменты для горных и землеройных работ | Многослойный композит | Высокая стойкость к ударам и истиранию |

| Советы специалиста | Индивидуальные приложения | Индивидуальные смеси твердых сплавов | Уникальные свойства в соответствии с потребностями |

Анализ сырья и состава

Твердосплавные паяные наконечники обязаны своим превосходством передовым материалам, используемым при их производстве. Эти материалы точно подобраны для удовлетворения конкретных промышленных требований. Давайте углубимся в их сырьевой состав.

- Карбид вольфрама (WC): Основной вид твердосплавных наконечников, обладающих непревзойденной твердостью и прочностью.

- Кобальт (Co): Используемый в качестве связующего вещества, кобальт удерживает зерна карбида вместе, обеспечивая прочность.

- Никель (Ni) и хром (Cr): Добавляют коррозионную стойкость и термостойкость.

- Карбид титана (TiC): Повышает износостойкость при работе на высоких скоростях.

- Другие добавки: Тонкая настройка таких свойств, как прочность, стойкость к окислению или теплопроводность.

Области применения наконечников с твердосплавной пайкой

Универсальность твердосплавных паяных наконечников поражает воображение. Вот как они проявляют себя в различных отраслях промышленности:

| Промышленность | Приложения | Ключевые преимущества |

|---|---|---|

| Автомобильная промышленность | Обработка деталей двигателя, нарезка зубчатых колес | Точность, скорость, долговечность |

| Аэрокосмическая промышленность | Компоненты реактивных двигателей, сверление планера | Высокая тепло- и износостойкость |

| Деревообработка | Обработка древесины, строгание и резьба | Ровные срезы и долговечные края |

| Добыча | Инструменты для бурения скальных пород и землеройных работ | Устойчивость к ударам и истиранию |

| Нефть и газ | Нарезание трубной резьбы, обработка клапанов | Коррозия и работа при высоких температурах |

| Изготовление металлоконструкций | Общая обработка, токарные работы | Универсальность и высокое качество отделки |

| Электроника | Сверление печатных плат и тонкая резка деталей | Точность на уровне микрона |

Технологический процесс производства Наконечники с твердосплавной напайкой

Вы когда-нибудь задумывались, как изготавливаются паяные наконечники из твердого сплава? Это кропотливый процесс, в котором задействованы передовые технологии и точные инженерные решения. Вот путь производства:

- Приготовление порошка: Вольфрам, кобальт и другие порошки смешиваются в нужный состав.

- Уплотнение: Порошок спрессовывается в нужную форму.

- Спекание: Спрессованные наконечники нагреваются при высоких температурах для достижения необходимой плотности и твердости.

- Измельчение: Точная шлифовка для получения острых кромок и заданных размеров.

- Пайка: Наконечник крепится к корпусу инструмента при помощи пайки с использованием высокотемпературных сплавов-наполнителей.

- Проверка и тестирование: Строгий контроль качества обеспечивает высочайшую производительность.

- Упаковка: Наконец, наконечники упаковываются для транспортировки и хранения.

Свойства материала твердосплавных паяных наконечников

| Недвижимость | Диапазон значений | Важность |

|---|---|---|

| Твердость | 89-94 HRA | Определяет износостойкость |

| Прочность на изгиб | 1500-3000 МПа | Указывает на устойчивость к изгибу под нагрузкой |

| Плотность | 14,5-15,5 г/см³ | Влияет на баланс и вес инструмента |

| Теплопроводность | 75-125 Вт/мК | Обеспечивает отвод тепла во время обработки |

| Модуль упругости | 450-700 ГПа | Проявляет жесткость и прочность |

| Вязкость разрушения | 9-13 МПа-м¹/² | Указывает на устойчивость к распространению трещин |

Основные характеристики: Состав и особенности

| Элемент | Процент (%) | Функциональность |

|---|---|---|

| Карбид вольфрама | 85-90 | Обеспечивает непревзойденную твердость режущей кромки |

| Кобальт | 8-12 | Связывает зерна карбида и придает прочность |

| Карбид титана | 0-3 | Повышает износостойкость |

| Хром | 0-1 | Повышает коррозионную стойкость |

Эксплуатационные параметры: Твердость, прочность и износостойкость

| Параметр | Оценка A | Оценка B | Оценка C |

|---|---|---|---|

| Твердость (HRA) | 92 | 90 | 88 |

| Прочность на изгиб (МПа) | 2500 | 2200 | 2000 |

| Износостойкость (мм³) | Высокая | Средний | Низкий |

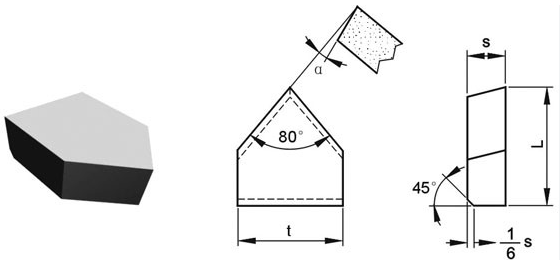

Технические характеристики, размеры, формы и стандарты

| Спецификация | Доступный диапазон | Стандарты |

|---|---|---|

| Размеры наконечника | 10-50 мм (L), 2-10 мм (T) | ISO 513, ANSI B212.1 |

| Формы | Круглые, квадратные, треугольные | ISO 1832 |

| Толерантность | ±0,02 мм | DIN 69881 |

Поставщики и ценовая политика

| Название поставщика | Регион | Диапазон цен (за единицу) | Время выполнения заказа |

|---|---|---|---|

| XYZ Carbide Inc. | Северная Америка | $2.00-$5.00 | 2-3 недели |

| Global Tool Parts | Европа | $1.50-$4.50 | 1-2 недели |

| Прецизионные твердые металлы | Азия | $1.00-$3.50 | 2-4 недели |

Выбор правильного Твердосплавный паяный наконечник

| Фактор | Ключевое соображение |

|---|---|

| Материал для резки | Твердые металлы против более мягких материалов, таких как дерево |

| Геометрия наконечника | Форма и углы для предполагаемого применения |

| Условия эксплуатации | Высокая температура, скорость или абразивные среды |

| Бюджет | Компромисс между стоимостью и производительностью |

| Репутация поставщика | Последовательность и гарантия качества |

Преимущества и ограничения

| Преимущества | Ограничения |

|---|---|

| Высочайшая твердость и износостойкость | Более высокая первоначальная стоимость |

| Универсальность в разных отраслях | Хрупкость при экстремальных воздействиях |

| Длительный срок службы инструмента и сокращение времени простоя | Требует точного обращения |

Вопросы и ответы

| Вопрос | Ответить |

|---|---|

| Что делает паяные наконечники из твердого сплава такими эффективными? | Они сочетают в себе твердость, прочность и жаропрочность. |

| Можно ли использовать твердосплавные наконечники повторно? | Их можно перешлифовать, но после многократного использования их характеристики могут ухудшиться. |

| Как выбрать лучший наконечник для моего проекта? | Учитывайте материал, форму и специфические требования к применению. |

| Дорогие ли твердосплавные наконечники? | Несмотря на более высокую первоначальную стоимость, их долговечность обеспечивает долгосрочную экономию. |