When it comes to tools used in manufacturing, machining, and other technical fields, the age-old debate of твёрдый сплав tools versus steel tools has always been a hot topic. Choosing between the two materials boils down to understanding their composition, performance, cost, and scope of application. This article dives deep into each aspect to help you make an informed decision, using an engaging, conversational style to simplify these complex details.

The Material Composition of Carbide Tools and Steel Tools

Understanding the material makeup of these tools is crucial because it directly affects their performance and longevity.

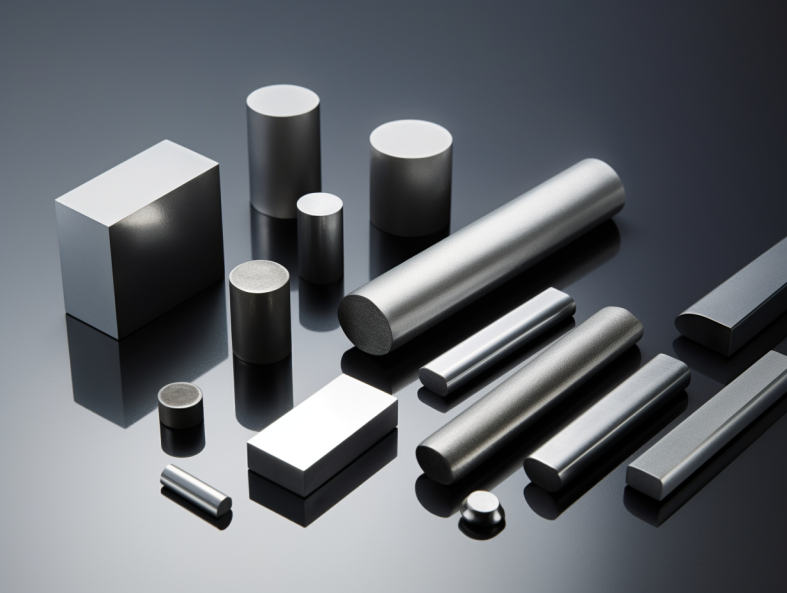

- Твердосплавные инструменты: These are typically made from a blend of tungsten carbide and a binding metal like cobalt. Tungsten carbide provides extreme hardness and wear resistance, while cobalt acts as a binder to hold the particles together. This combination creates a dense, durable tool capable of handling high-speed machining.

- Стальные инструменты: High-speed steel (HSS) tools, on the other hand, are alloys of steel containing tungsten, molybdenum, chromium, and vanadium. This mix improves hardness, toughness, and resistance to wear but doesn’t quite reach the extreme hardness of carbide tools.

Think of carbide tools as a diamond sword—sharper and more robust but also prone to chipping under certain conditions. Steel tools, in contrast, are like a trusty, rugged hammer—versatile and forgiving.

The Hardness and Strength of Твердый сплав Tools and Steel Tools Are Different

| Параметр | Твердосплавные инструменты | Стальные инструменты |

|---|---|---|

| Твердость | Extremely high (up to 9 on Mohs scale) | Moderate (5-7 on Mohs scale) |

| Жесткость | Хрупкая, склонная к образованию сколов при ударе | More ductile, can absorb impacts well |

| Износостойкость | Excellent, retains sharpness over time | Good, but dulls faster under heavy use |

Insights:

Carbide tools are your go-to for precision and durability in high-stress environments. However, if you need a tool that can take a beating, steel tools are often better suited.

The Heat Resistance of Carbide Tools and Steel Tools Is Different

Temperature resistance is critical, especially for tools used in high-speed or high-friction applications.

- Твердосплавные инструменты: These shine in high-temperature conditions, maintaining hardness and edge sharpness even when cutting metals at thousands of RPMs.

- Стальные инструменты: While high-speed steel can tolerate elevated temperatures, it tends to lose hardness more quickly when compared to carbide. Excessive heat can lead to faster tool wear and deformation.

The Processing Speed of Carbide Tools and Steel Tools Is Different

| Параметр | Твердосплавные инструменты | Стальные инструменты |

|---|---|---|

| Optimal Cutting Speed | Very high (150-300 m/min) | Moderate (30-70 m/min) |

| Machining Efficiency | Extremely efficient in high-speed cuts | Slower but more forgiving for operators |

| Surface Finish Quality | Superior finish at high speeds | Adequate, but rougher at similar speeds |

Insights:

If you’re racing against the clock, carbide tools can handle higher speeds without breaking a sweat. Steel tools, while slower, offer better control for intricate tasks.

The Cost Difference Between Твердый сплав Tools and Steel Tools

| Аспект | Твердосплавные инструменты | Стальные инструменты |

|---|---|---|

| Первоначальная стоимость | Significantly higher | Доступный |

| Продолжительность жизни | Longer, requires less frequent replacement | Shorter, wears out faster |

| Cost Efficiency Over Time | High for long-term use | Low for high-intensity operations |

Insights:

The upfront cost of carbide tools might make you wince, but they often pay for themselves in long-term performance. Steel tools are budget-friendly but may need more frequent replacements.

The Scope of Application for Carbide Tools and Steel Tools Is Different

- Твердосплавные инструменты: Perfect for machining hard materials like titanium, hardened steel, and cast iron. They’re widely used in industries where precision, speed, and wear resistance are critical, such as aerospace and automotive manufacturing.

- Стальные инструменты: Better suited for softer materials and general-purpose tasks. They’re ideal for woodworking, plastic cutting, and low-stress metalworking applications.

Think of it like this: carbide tools are the Ferraris of the tool world—built for speed and performance—while steel tools are dependable SUVs, versatile and economical.

The Maintenance and Repair of Carbide Tools and Steel Tools Are Different

| Аспект | Твердосплавные инструменты | Стальные инструменты |

|---|---|---|

| Заточка | Требуется специализированное оборудование | Can be sharpened with standard grinders |

| Durability Under Stress | Prone to chipping if mishandled | More forgiving of operator errors |

| Ease of Repair | Difficult, often replaced when damaged | Easier to repair and maintain |

Insights:

Maintaining carbide tools is more like taking care of fine china—specialized and delicate. Steel tools are easier to manage, making them suitable for less experienced users.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

| Вопрос | Ответить |

|---|---|

| Which tool is better for beginners? | Steel tools, as they are more forgiving and easier to handle. |

| Can carbide tools be used for woodworking? | Yes, but they’re typically overkill for softer materials like wood. |

| Are carbide tools worth the higher cost? | If you value speed, precision, and longevity, absolutely. |

| Do steel tools work well for heavy metals? | They can, but they wear out faster than carbide tools in such applications. |

Заключительные размышления

Choosing between твёрдый сплав tools and steel tools is not just about the tool itself; it’s about what you need it for. If you’re after high-speed machining, long-term performance, and a professional finish, carbide tools are your champion. For cost-effectiveness, versatility, and user-friendliness, steel tools remain a reliable choice.

Ultimately, it boils down to your budget, the material you’re working with, and the level of precision required. No matter your choice, both materials have carved out their niches, proving invaluable in their respective domains.