What is Carbide Plate Hardfacing?

Ever wondered why some industrial equipment seems to survive even the harshest environments, while others wear out way too quickly? The answer often lies in a technique called твёрдосплавная пластина hardfacing.

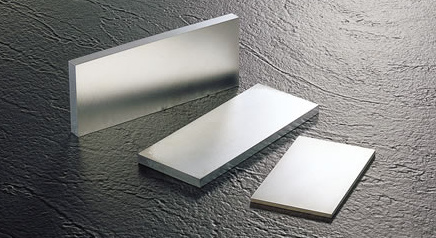

At its core, hardfacing is the process of applying a wear-resistant layer—typically made from a hard alloy like tungsten or chromium carbide—onto the surface of a metal component. This layer increases the durability of the component and prolongs its service life. Think of it as armor plating for your machinery.

Now, when we say “carbide plate hardfacing,” we’re specifically talking about attaching or fusing carbide-infused plates onto vulnerable surfaces. These plates are packed with hard metal powders, creating a barrier that’s incredibly tough against abrasion, impact, heat, and even corrosion. Carbide plates are like the knights of medieval times—battle-tested, rugged, and nearly indestructible when it counts.

Carbide plate hardfacing isn’t just a fancy solution; it’s a necessity in industries like mining, construction, oil & gas, agriculture, and power generation. Any place where wear and tear are frequent foes, hardfacing steps in as the reliable line of defense.

Benefits of Carbide Hardfacing Plates

Let’s face it—no one wants to be replacing parts every few weeks or dealing with downtime. That’s where carbide hardfacing plates shine.

1. Extreme Wear Resistance

These plates are infused with metal carbides like вольфрам и chromium, which are among the hardest materials known to man. Tungsten carbide, for example, ranks around 9 on the Mohs hardness scale. That’s just one notch below diamonds!

2. Longer Equipment Lifespan

Replacing machine components isn’t cheap. With hardfacing, parts can last up to 10 times longer, reducing maintenance cycles and downtime.

3. Экономическая эффективность

Sure, carbide plates cost more upfront. But over time, they save thousands by avoiding frequent part replacements. It’s the difference between buying a high-end coffee maker once and replacing a cheap one every six months.

4. Heat and Corrosion Resistance

High-temperature environments? No problem. Carbide plates resist oxidation and maintain integrity in temperatures exceeding 1000°C.

5. Versatility in Use

From bulldozers to coal crushers to grain conveyors—hardfaced plates adapt to various shapes and surfaces. They can be rolled, cut, or welded to meet your needs.

Типы Твердосплавные пластины

There are several types of carbide plates, each tailored for specific applications. Understanding their differences helps you make a smarter choice for your operation.

1. Tungsten Carbide Plates

Arguably the toughest of the bunch. Tungsten carbide is a compound of tungsten and carbon, boasting incredible hardness and thermal resistance.

Плюсы: Extremely hard, heat-resistant, excellent abrasion protection

Конс: More expensive, brittle under high impact

2. Chromium Carbide Plates

Perfect for environments with sliding wear and moderate impact. Chromium carbide is also known for its excellent corrosion resistance.

Плюсы: Corrosion-resistant, durable under moderate stress

Конс: Not ideal for high-impact situations

3. Niobium Carbide Plates

Known for high toughness and wear resistance, even under impact. Often used in mixing equipment.

Плюсы: Tough, resistant to fracturing

Конс: Less wear resistance than tungsten or chromium

4. Boron Carbide Plates

Used in very specific applications, especially where lightness and extreme hardness are essential.

Плюсы: Very lightweight, hard

Конс: Expensive, rare

Common Metal Powder Models Used in Carbide Hardfacing Plates

Below are 10 specific metal powder models widely used in the production of carbide hardfacing plates, each with unique compositions and advantages:

| Модель металлического порошка | Состав | Primary Features | Приложения |

|---|---|---|---|

| WSC10 | 10% Cobalt, 90% WC | High hardness, corrosion resistance | Mining tools, drill bits |

| CrFeC65 | Chromium, Iron, Carbon | Tough against moderate abrasion | Agricultural blades, fans |

| TungHard45 | 45% Tungsten | Very high abrasion resistance | Earthmoving equipment |

| NbC25 | 25% Niobium Carbide | Great under impact stress | Mixing paddles |

| CrC75 | 75% Chromium Carbide | Excellent sliding wear protection | Conveyor liners |

| BoroShield | Boron Carbide Alloy | Lightweight, ultra-hard | Lightweight armor |

| TiC60 | 60% Titanium Carbide | High toughness, wear resistance | Industrial knives |

| WC-Co75 | 75% Tungsten Carbide, Cobalt matrix | Superior hardness and binder strength | High-speed cutting tools |

| NiCrSiB | Nickel, Chromium, Silicon, Boron | Good for thermal spraying | Tubes, pipes |

| ZrC20 | Карбид циркония | Высокая теплопроводность | High-temp furnaces |

Типичные применения Твердосплавная пластина Наплавка

Carbide hardfacing plates are used across multiple industries. Let’s walk through some real-world scenarios:

Добыча

Equipment like chutes, hoppers, and crushers are constantly bombarded by abrasive rocks. Hardfaced plates ensure these components last longer.

Строительство

Bulldozer blades, excavator buckets, and loaders benefit from the abrasion resistance of carbide plates, helping them plow through dirt and stone without wearing down.

Нефть и газ

In the downhole tools and pipeline components, carbide plates provide protection against erosion and extreme temperatures.

Сельское хозяйство

Harvesters and plows often face soil, stones, and tough vegetation. Hardfacing increases their durability significantly.

Производство электроэнергии

Fly ash handling systems and coal mills in power plants are another perfect match for carbide hardfacing plates.

Hardfacing Process Overview

How do we get those super-tough plates? Here’s a quick peek into the magic behind the curtain.

1. Surface Preparation

It all starts with a clean surface. Any contaminants or rust are removed to ensure a solid bond.

2. Application Methods

There are various techniques used to apply the metal powder to the base plate:

- Welding (MIG, TIG, PTA): Common for thick overlays

- Thermal Spraying: Great for thin, precise coatings

- Laser Cladding: High-precision, low dilution

- Пайка: Used in low-stress environments

3. Post-Treatment

After application, the surface is often ground or polished. Some parts may undergo heat treatment to improve bonding and toughness.

Выбор правильного Твердосплавная пластина Поставщик

This part’s important—almost as important as picking the right material. A bad supplier can mean inconsistent quality, unreliable delivery, and zero tech support.

Factors to Consider:

- Reputation and Experience: Look for suppliers with years in the business and great customer feedback.

- Сертификаты: ISO standards, lab test reports, and batch traceability are all green flags.

- Техническая поддержка: Do they help you choose the right alloy? Customize the plate design?

- Производственные мощности: Can they meet your volume demands? Especially important for large operations.

- Lead Times and Logistics: Delays can cost you big time. Make sure your supplier has a robust supply chain.

Some well-known global suppliers include Hardcarb Technologies, Castolin Eutectic, SSAB, и VAUTID.

Вопросы и ответы

| Вопрос | Ответить |

|---|---|

| What metals are commonly used in carbide plates? | Tungsten, chromium, niobium, boron, titanium, and cobalt alloys. |

| How thick can hardfacing layers be? | It depends on the method, but generally from 1mm to over 20mm. |

| Can carbide plates be cut and welded? | Yes, with special tools. Plasma cutting and low-hydrogen welding are common. |

| What’s the lifespan compared to non-hardfaced parts? | Usually 3–10x longer, depending on wear conditions. |

| Are carbide plates recyclable? | Yes, but with specialized recycling processes due to their hardness. |

| Can I use carbide plates for both impact and abrasion? | Some can handle both, like tungsten carbide; others are better suited for one type. |

| Is it better to use thermal spraying or welding? | Depends on the thickness and application. Welding is better for thick layers; spraying for thin. |

| How do I store carbide plates? | Keep in a dry, clean environment to avoid oxidation. |

| Are there environmental hazards with hardfacing? | Some fumes during welding can be hazardous. Proper ventilation and PPE are essential. |

| What’s the lead time for custom orders? | Typically 2-6 weeks, but varies by supplier and complexity. |