Преимущества Твердосплавные стержни in Precision Drilling

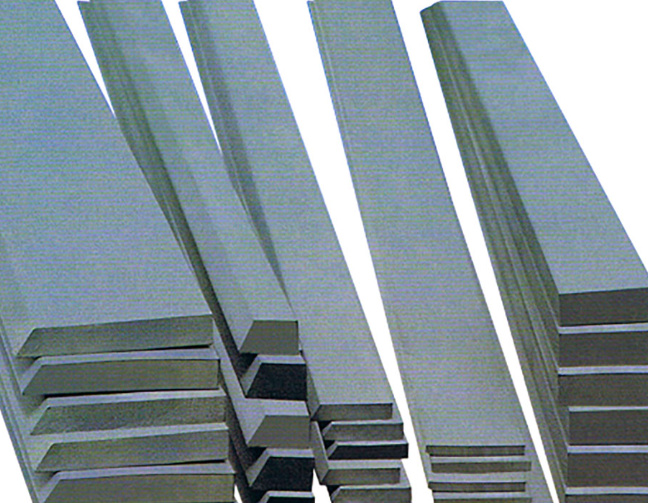

When it comes to precision drilling, carbide rods are the unsung heroes behind the scenes. Made from tungsten carbide—a compound of tungsten and carbon—they offer exceptional hardness and wear resistance. This means they can maintain sharpness and structural integrity even under high-speed drilling conditions, reducing the frequency of tool replacements and downtime.

One of the standout features of carbide rods is their ability to withstand high temperatures without losing hardness. This property is crucial during drilling operations where heat generation is inevitable. Moreover, their rigidity minimizes deflection, ensuring holes are drilled with high precision and accuracy.

Applications of Carbide Rods in Drilling

Carbide rods find applications across various industries due to their superior properties:

- Aerospace and Automotive Industries: Used in manufacturing components that require high precision and durability.

- Medical Field: Essential in creating surgical instruments and implants where accuracy is paramount.

- Разведка нефти и газа: Ideal for drilling equipment that must withstand harsh environments.

- Металлообработка: Utilized in making end mills, reamers, and other cutting tools.

Their versatility makes carbide rods indispensable in any application where precision drilling is required.

Why Choose Твердосплавные стержни Over Alternatives

When comparing carbide rods to other materials like high-speed steel (HSS) or cobalt alloys, several advantages become evident:

- Твердость и износостойкость: Carbide rods are significantly harder than HSS, allowing them to cut through tough materials with ease and maintain their edge longer.

- Термостойкость: They can operate at higher temperatures without losing hardness, unlike HSS which may soften.

- Точность: The rigidity of carbide rods ensures minimal deflection, leading to more accurate drilling.

While carbide rods may have a higher upfront cost, their longevity and performance often result in lower overall expenses due to reduced tool changes and downtime.

Specifications & Buying Guide

When selecting carbide rods for precision drilling, consider the following specifications:

- Diameter and Length: Available in various sizes to suit different applications.

- Класс: Different grades offer varying hardness and toughness levels.

- Отверстия для охлаждающей жидкости: Some rods come with straight or helical coolant holes to facilitate heat dissipation during drilling.

- Отделка поверхности: Depending on the application, rods may have polished or unpolished surfaces.

It’s essential to match the rod’s specifications with the intended application to achieve optimal performance.

Топ-10 моделей металлических порошков для Твердосплавные стержни

The performance of carbide rods is significantly influenced by the metal powder used in their production. Here are ten notable models:

| Модель | Состав | Описание |

|---|---|---|

| YG6 | 6% Кобальт | Offers excellent hardness and wear resistance; ideal for general machining. |

| YG8 | 8% Cobalt | Provides a balance between hardness and toughness; suitable for mining and drilling applications. |

| YG10 | 10% Cobalt | Enhances toughness; used for cutting tools requiring high precision. |

| YG15 | 15% Cobalt | Increased toughness and durability; perfect for heavy-duty cutting and wear parts. |

| YW1 | WC-Co Blend | Versatile grade with good wear resistance and toughness. |

| YW2 | WC-Co Blend | Аналогична YW1, но с немного более высоким содержанием кобальта для повышения прочности. |

| K10 | Fine-Grained WC | Ideal for precision machining and cutting tools. |

| K20 | WC-Co Blend | Balances hardness and toughness; used in metal forming and cutting. |

| C2 | WC-Co Blend | Known for general-purpose applications; provides good wear resistance and impact strength. |

| C3 | WC-Co Blend | Offers higher toughness; suitable for interrupted cuts and roughing applications. |

Selecting the appropriate metal powder model is crucial for achieving desired performance characteristics in carbide rods.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

| Вопрос | Ответить |

|---|---|

| Что такое карбид вольфрама? | A composite material made of tungsten and carbon, known for its exceptional hardness and durability. |

| Why use carbide rods with holes? | Они обладают высокой точностью, износостойкостью и долговечностью, что делает их идеальными для различных промышленных применений. |

| How are holes in carbide rods made? | Typically drilled using specialized equipment before the grinding process. |

| What industries use carbide rods with holes? | Manufacturing, mining, automotive, aerospace, medical, and engineering industries. |

| What are common grades of tungsten carbide? | К распространенным маркам относятся YG6, YG8, YG10, YG15, YW1, YW2, K10, K20, C2 и C3. |

| How to select the right carbide rod? | Consider application requirements such as hardness, toughness, wear resistance, and the specific grades suitable for those needs. |