概要

精密機械加工では、適切な工具を選択することで大きな違いが生まれます。そのような重要な工具の一つが、PVDコーティングされた超硬チップです。これらのチップは、加工工程の効率、精度、寿命を高める上で極めて重要です。しかし、何がそれほど特別なのでしょうか?他の選択肢と比べてどうなのか?また、どのようにして特定のニーズに最適なものを選択できるのでしょうか?この広範なガイドでは、以下について知る必要があるすべてを深く掘り下げていきます。 PVDコーティング超硬チップその組成や特性から、用途や選択基準まで。

PVDコーティング超硬インサートとは?

PVD(物理的気相成長)コーティングされた超硬チップは、様々な機械加工に使用される切削工具です。PVDプロセスでは、超硬基材に薄く硬いコーティング材を蒸着させます。このコーティングは、優れた硬度、耐摩耗性、耐熱性によりチップの性能を向上させ、工具の寿命を延ばし、加工製品の品質を向上させます。

PVDコーティング超硬インサートの主な特長

- 硬度の向上: PVDコーティングは、超硬チップの表面硬度を著しく高め、耐摩耗性と耐変形性を向上させる。

- 耐摩耗性の向上: コーティングは、インサートの摩耗率を低減し、長期間にわたって安定した性能を保証する。

- 耐熱性の向上: PVDコーティングは高温に耐えることができるため、これらのチップは高速加工に最適です。

- 摩擦の低減: 滑らかで硬いコーティングは、チップとワーク間の摩擦を低減し、加工面の品質を向上させる。

PVDコーティング超硬インサートの種類

| モデル | 説明 |

|---|---|

| TNMG 160404-PF | 耐摩耗性、耐久性に優れた鋼、ステンレス、鋳鉄用の汎用チップ。 |

| CNMG 120408-MF | 鉄鋼およびステンレス鋼の仕上げおよび半仕上げに最適で、高い精度と表面品質を提供する。 |

| DNMG 150608-PF | 鋼や鋳鉄の高速旋削加工に適しており、優れた切りくず処理性と耐摩耗性を発揮。 |

| WNMG 080404-MF | 鋼、ステンレス鋼、高温合金を含む幅広い材料に対応する万能チップ。 |

| SNMG 120408-QM | ステンレス鋼および鋼の荒加工および仕上げ加工用に設計されており、高い性能と工具寿命を保証。 |

| VNMG 160404-MF | 鋼およびステンレス鋼の精密仕上げ用精密チップで、優れた仕上げ面と精度を実現。 |

| CCMT 09T304-PF | 小物部品加工に最適で、優れた刃先安定性と耐摩耗性を発揮。 |

| DCMT 11T304-MF | 小物部品の高精度旋削加工に最適で、優れた切りくず処理と仕上げ面精度を実現。 |

| SCMT 09T304-PF | 鋼やステンレスの中・荒加工用に設計され、長い工具寿命と安定性を提供。 |

| RCMT 10T3MO | 鋳鉄および非鉄金属の荒加工および中仕上げに使用され、高い耐摩耗性を発揮。 |

応用例 PVDコーティング超硬インサート

| 申し込み | 説明 |

|---|---|

| スチール加工 | 各種鋼種の高速・精密加工に最適。 |

| ステンレス加工 | ステンレス鋼の加工で優れた性能を発揮し、摩耗を低減して工具寿命を延長。 |

| 鋳鉄加工 | 鋳鉄の荒加工と仕上げ加工に適しており、高い耐久性と耐摩耗性を発揮する。 |

| 非鉄金属加工 | アルミニウム、銅、その他の非鉄金属の加工に最適で、工具の摩耗を最小限に抑えます。 |

| 高温合金 | 超合金、チタン、その他の高温材料の加工に最適。 |

材料特性

| プロパティ | 説明 |

|---|---|

| 硬度 | PVDコーティングによる表面硬度の向上、通常2000HV以上。 |

| タフネス | 超硬基材のコア靭性を維持し、耐チッピング性と耐欠損性を確保。 |

| 耐摩耗性 | 非コーティングまたは従来のコーティングされたチップと比較して、優れた耐摩耗性。 |

| 耐熱性 | 高温に耐えることができ、高速加工に適している。 |

組成、特性、特徴

| コンポーネント | プロパティ | 特徴 |

|---|---|---|

| 超硬基板 | 高い靭性と硬度を持ち、PVDコーティングの強固な下地となる。 | 耐久性と機械的ストレスへの耐性を確保。 |

| PVDコーティング | TiN、TiAlN、AlCrNなどの薄くて硬い層は、優れた耐摩耗性を提供する。 | 摩擦を減らし、耐摩耗性を高め、耐熱性を高める。 |

| バインダー段階 | 通常はコバルトかニッケルで、炭化物粒を結合させる。 | インサートの靭性と構造的完全性を維持する。 |

硬度、強度、耐摩耗性

| パラメータ | 説明 |

|---|---|

| 硬度(HV) | コーティング材にもよるが、通常2000から3000HVの範囲。 |

| 曲げ強度 | 高い曲げ強度で、加工中の機械的応力に耐える。 |

| 耐摩耗性 | 優れた耐摩耗性により、非コーティングチップに比べて工具寿命を大幅に延長。 |

仕様、サイズ、形状、規格

| 仕様 | 説明 |

|---|---|

| ISO規格 | インサートはISO規格に準拠しており、互換性と性能を保証します。 |

| サイズ | さまざまな加工ニーズやツールホルダーに合わせて、さまざまなサイズをご用意しています。 |

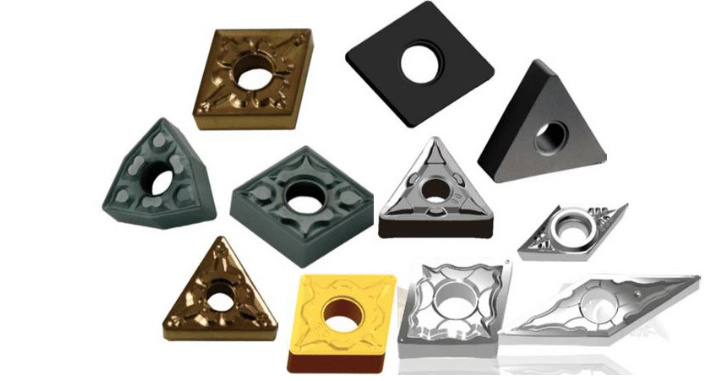

| シェイプス | 一般的な形状には、三角形、正方形、ひし形、円形、平行四辺形などがある。 |

サプライヤーと価格詳細

| サプライヤー | 製品範囲 | 価格帯 |

|---|---|---|

| サンドビック・コロマント | 様々な用途のPVDコーティング超硬チップを幅広く取り揃えています。 | 仕様により、インサート1個につき$10~$50。 |

| ケナメタル | 様々な材料に対応する高度なPVDコーティングを施した高性能チップ。 | 仕様により、インサート1個につき$12~$55。 |

| セコ・ツールズ | 様々な加工タスクに最適なPVDコーティングを施したチップの包括的なセレクション。 | 仕様により、インサートあたり$11~$48。 |

| 三菱マテリアル | 優れたPVDコーティングを施した革新的なインサートで、性能を強化。 | 仕様により、インサート1個につき$13~$60。 |

| 京セラ | 幅広い材料と用途に対応する汎用性の高いPVDコーティングチップ。 | 仕様により、インサートあたり$9~$45。 |

正しいPVDコーティング超硬インサートの選び方

| 考察 | 説明 |

|---|---|

| 加工する材料 | 加工する材料(鋼、ステンレス鋼、鋳鉄など)に応じてチップを選択する。 |

| 機械加工 | 荒加工、仕上げ加工、中仕上げ加工のいずれにチップが必要かを判断してください。 |

| 切断速度 | 用途に必要な切削速度に耐えるチップを選択する。 |

| ツールホルダー互換性 | インサートが既存のツールホルダーや機械に適合することを確認してください。 |

| コストと予算 | インサートの費用対効果を検討し、性能と予算のバランスをとる。 |

PVDコーティング超硬インサートの利点と限界

| アスペクト | メリット | 制限事項 |

|---|---|---|

| 耐久性 | 非コーティングチップに比べ、工具寿命が大幅に向上。 | 初期コストは、非コーティングや従来のコーティングを施したインサートよりも高くなる可能性がある。 |

| パフォーマンス | 高速・精密加工で優れた性能を発揮。 | 最適な性能を発揮するために、特定のツールホルダーや機械が必要になる場合がある。 |

| コスト | 工具の交換やダウンタイムを削減できるため、長期にわたって費用対効果が高い。 | 初期費用が高い。 |

| 汎用性 | 幅広い材料と加工に対応。 | すべてのPVDコーティングがすべての材料に適しているわけではなく、特定の用途には特定のコーティングが必要です。 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| PVDコーティングされた超硬チップの主な利点は何ですか? | 硬度、耐摩耗性、耐熱性が向上し、工具寿命が延びる。 |

| PVDコーティングされたインサートは、すべての材料に使用できますか? | 汎用性がある一方で、特定のコーティングは鋼鉄、ステンレス鋼、鋳鉄など特定の素材に最適化されている。 |

| 自分の用途に合ったインサートを選ぶには? | 加工する材料、加工の種類、切削速度、ツールホルダの互換性などの要素を考慮してください。 |

| PVDコーティングされたインサートは、コーティングされていないものより高価ですか? | 初期コストは高いが、摩耗が少なく工具寿命が長いため、長期的には費用対効果が高くなる。 |

| PVDコーティングされたチップは加工品質を向上させることができますか? | そう、摩擦と摩耗を減らし、表面仕上げと寸法精度を向上させるのだ。 |

結論

正しい選択 PVDコーティング超硬チップ は、加工作業の効率、品質、費用対効果に大きな影響を与えます。これらのチップの様々な種類、用途、特性を理解することで、製造工程を強化するための十分な情報に基づいた決定を下すことができます。鋼、ステンレス鋼、鋳鉄、非鉄金属の加工にかかわらず、お客様のニーズを満たし、期待を上回ることができるPVDコーティングチップがあります。