機械加工と切削工具の世界では、その形状と設計が重要である。 カーバイド ブレージングチップは、その切断性能を決定する重要な役割を果たします。小さいながらも非常に強力なこの部品は、過酷な条件に耐え、正確で効率的な切削を実現するように設計されています。このブログでは、超硬ブレージングチップの形状と設計の複雑さを掘り下げ、これらの要因が切削性能にどのように影響するか、また、工具効率を最適化するためにどのような考慮が不可欠かを探ります。

概要

超硬ろう付けチップは、その卓越した硬度と耐摩耗性により、さまざまな産業で広く使用されています。これらのチップの形状と設計は、切削性能を高め、工具の摩耗を減らし、全体的な加工効率を向上させるために細心の注意を払って作られています。形状やデザインが切削性能に与える影響を理解することは、適切な工具を選択し、さまざまな用途で最適な結果を得るために不可欠です。

超硬ろう付けチップの形状と設計の詳細紹介

超硬ブレージングチップ形状とは?

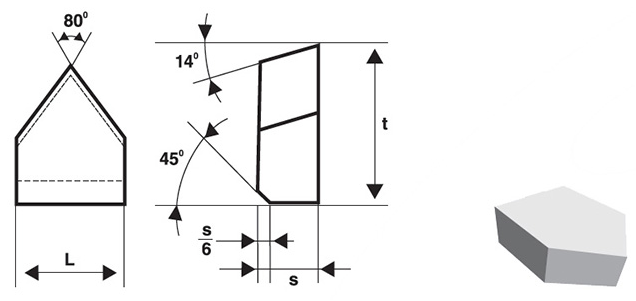

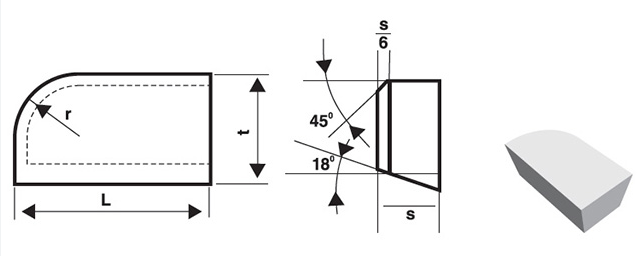

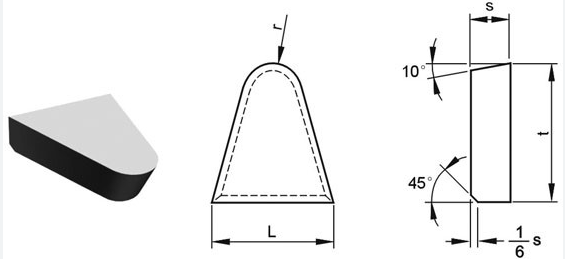

超硬ろう付けチップの形状とは、刃先とチップ表面の形状、角度、寸法を指します。主な幾何学的パラメータは以下の通りです:

- レーキの角度: 切れ刃と被削材表面のなす角。切りくずの生成や切削力に影響する。

- リリーフアングル: 工具の逃げ面と被削材の表面との間の角度で、こすれを防ぎ、摩擦を減らす。

- カッティングエッジの角度: すくい面と逃げ面が交差してできる角度で、工具の強度と耐摩耗性に影響する。

- コーナー半径: 工具先端のエッジが丸くなり、仕上げ面と工具寿命に影響を与える。

デザインはカッティング性能にどう影響するか?

超硬ブレージングチップの設計には、切れ刃の配置、材料の配分、チップブレーカーやコーティングなどの追加機能を含む全体的な構造が含まれます。これらの設計要素は、形状と調和して切削性能を最適化します。主な設計要素は以下の通りです:

- 先端の形状: 異なる形状(例えば、正方形、円形、ダイヤモンド)は、特定の用途や材料に適しています。

- チップ・ブレーカーズ 切り屑の流れをコントロールし、切り屑の詰まりを防ぐことで、切削効率を向上させる機能を搭載。

- コーティング: 摩擦を減らし、耐摩耗性を高め、工具寿命を延ばす保護層。

形状と設計が切削性能に与える影響

超硬ろう付けチップの形状と設計は、切削性能のいくつかの重要な側面に直接影響します:

1.切断効率

- レーキの角度: 正のすくい角は、切削力とエネルギー消費を低減し、能率を向上させる。しかし、工具強度が低下する可能性がある。

- リリーフアングル: 適度な逃げ角が摩擦や熱の蓄積を防ぎ、切削効率を高める。

2.工具寿命

- カッティングエッジの角度: 大きな切れ刃角により、強度と耐摩耗性が向上し、工具寿命が延びる。

- コーナー半径: 大きなコーナ半径は、切削力をより均等に分散し、摩耗を減らして工具寿命を延ばす。

3.表面仕上げ

- レーキ角とレリーフ角: 角度を最適化することで、よりスムーズなカットが可能になり、表面仕上げも向上します。

- コーナー半径: 半径を大きくすれば仕上げ面精度は向上するが、高い切削力が必要になる場合がある。

4.チップコントロール

- チップ・ブレーカーズ 適切に設計されたチップブレーカは、切りくずの流れを管理し、詰まりを防止して切断効率を維持します。

- レーキの角度: 切り屑の形成と流れに影響を与え、全体的な切り屑のコントロールに影響を与える。

超硬ブレージングチップを選択する際の考慮要素

適切な超硬ろう付けチップを選択するには、形状と設計に関連するいくつかの要素を考慮する必要があります:

- 加工される素材: 最適な切断性能を得るためには、さまざまな材料に特有の形状と設計が必要です。

- 切断条件: 切削速度、送り速度、切り込み深さなどの要因は、チップ形状の選択に影響を与える。

- 機械加工の用途 加工作業の種類(旋盤加工、フライス加工、ドリル加工など)によって、適切なチップの設計が決まる。

- ツールホルダーと機械の互換性: 超硬ブレージングチップがツールホルダーと機械の仕様に適合していることを確認する。

超硬ろう付けチップ形状の比較分析

下表は、さまざまな幾何学的パラメータが切削性能に与える影響を示している:

| 幾何学的パラメータ | ポジティブな影響 | マイナスの影響 |

|---|---|---|

| レーキ角度 | 切断力の低減、効率の向上 | 工具強度の低下 |

| リリーフアングル | 摩擦の低減、表面仕上げの向上 | 過度の場合、工具の摩耗が増加する可能性がある |

| 刃先角度 | 工具強度の向上、工具寿命の延長 | より高い切断力 |

| コーナー半径 | 表面仕上げの向上、摩耗の低減 | 高い切削力、びびりの可能性 |

超硬ろう付けチップの用途

超硬ろう付けチップは、さまざまな業界の幅広い用途で使用されています。主な用途をいくつかご紹介します:

1.金属加工

- ターニング・オペレーション: 円筒部品の精密加工。

- フライス作業: フライス加工における効率的な材料除去。

- 掘削作業: 様々な被削材への高性能穴あけ。

2.木工

- カッティングとシェイピング: 木製部品の精密切断と成形。

- ルーティング: 複雑なデザインやパターンの高速ルーティング。

3.自動車産業

- エンジン部品加工: エンジン部品の精密加工により、最適なパフォーマンスを実現。

- トランスミッション部品製造: トランスミッション部品の高精度加工。

4.航空宇宙産業

- 航空機部品加工: 航空機の重要部品を高精度に加工。

- ランディングギアの加工 ランディングギア部品の耐久性と精密加工。

各メーカーの超硬ろう付けチップの比較

下の表は、主要パラメータに基づいて、さまざまなサプライヤーの超硬ろう付けチップを比較したものです:

| サプライヤー | 所在地 | 価格帯(1個あたり) | 特産品 |

|---|---|---|---|

| ケナメタル | アメリカ | $10 – $50 | 高性能カッティングチップ、カスタム形状 |

| エレメント・シックス | 英国 | $12 – $55 | 高度な設計、精密工学 |

| TRUER | 中国 | $8 – $45 | 費用対効果の高いソリューション、大量生産 |

| 住友電工 | 日本 | $15 – $60 | 革新的なデザイン、優れた品質管理 |

さまざまな形状の長所と短所

下の表は、さまざまな超硬ろう付けチップ形状の長所と短所をまとめたものです:

| 幾何学 | メリット | デメリット |

|---|---|---|

| ポジティブ・レーキ | 切削抵抗の低減、チップフローの改善 | 工具強度が低く、チッピングの可能性がある |

| ネガティブ・レーキ | 工具強度が向上し、硬い素材に最適 | 高い切断力、消費電力の増加 |

| 大きなコーナー半径 | 仕上げ面の向上、工具摩耗の低減 | 高い切削力、びびりの可能性 |

| 小コーナー半径 | より低い切断力、正確な切断 | 工具摩耗の増加、表面仕上げ不良の可能性 |

関連トピック超硬ブレージングチップ用アドバンストコーティング

超硬ブレージングチップの性能を高めるには、形状や設計に加えて、高度なコーティングが重要な役割を果たします。窒化チタン(TiN)、炭窒化チタン(TiCN)、窒化アルミニウムチタン(AlTiN)などのコーティングは、さらなる利点をもたらします:

- 摩擦の低減: コーティングは工具と被削材間の摩擦を減らし、切削効率を高める。

- 耐摩耗性の向上: コーティングは工具を摩耗から守り、寿命を延ばす。

- 耐熱性の向上: コーティングは放熱を助け、工具の熱損傷を防ぐ。

高性能加工に超硬ろう付けチップを選ぶ理由

超硬ブレージングチップは、その優れた硬度、耐摩耗性、過酷な条件下でも切削効率を維持する能力により、高性能加工に最適です。最適化された形状と高度な設計の組み合わせにより、これらの工具は正確で効率的な切削を実現し、様々な産業で欠かせないものとなっています。

よくあるご質問

1.すくい角は切削性能にどのように影響しますか?

A: すくい角は切りくずの形成と切削力に影響する。正のすくい角は切削抵抗を減らし、能率を向上させるが、工具強度を損なう可能性がある。

2.超硬ブレージングチップにおける逃げ角の重要性は?

A: 逃げ角は、工具とワーク間の摩擦や熱の蓄積を防ぎ、切削効率を高め、工具の摩耗を低減する。

3.チップブレーカーはどのように切削性能を高めるのですか?

A: チップブレーカーは、切りくずの流れを制御し、詰まりを防止することで、切削効率を維持し、工具損傷のリスクを低減します。

4.コーナーの半径を選択する際に考慮すべき要素は?

A: コーナ半径は仕上げ面と工具摩耗に影響する。半径を大きくすると、仕上がりが向上し、摩耗が減少するが、高い切削力が必要になる。

5.コーティングは超硬ブレージングチップの性能をどのように向上させますか?

A: コーティングは摩擦を減らし、耐摩耗性を高め、熱放散を改善し、工具の全体的な性能と寿命を向上させる。

超硬ブレージングチップの切削性能に及ぼす形状と設計の影響を理解することで、これらの工具を選択・使用する際に、十分な情報に基づいた意思決定を行うことができます。この知識は、最適な加工結果の達成、効率の向上、切削工具の寿命延長に役立ちます。