超硬熱処理とは?

カーバイド 熱処理 は、炭化物を主成分とする材料の硬度、靭性、耐摩耗性を向上させるために使用される特殊な熱処理です。このプロセスでは、炭化タングステン(WC)や炭化チタン(TiC)などの炭化物複合材料の微細構造を修正するために、精密な加熱と制御された冷却が行われる。

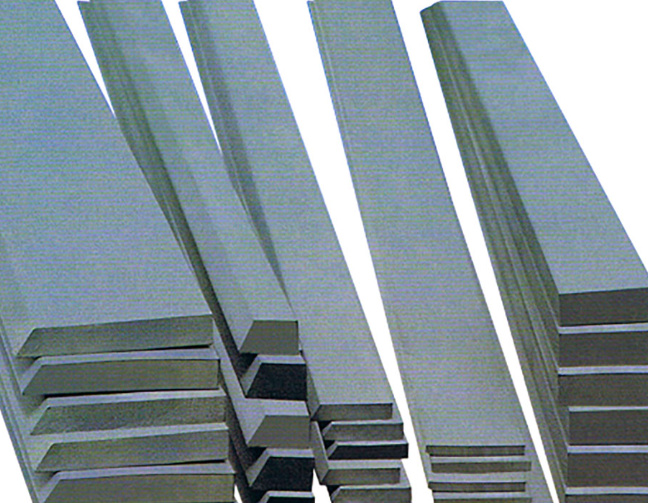

超硬材料は、高い耐摩耗性と強度が要求される産業用途に広く使用されています。切削工具から航空宇宙部品に至るまで、熱処理はこれらの材料の耐久性と過酷な条件下での最適な性能を確保するための精錬に不可欠です。しかし、なぜ超硬合金の熱処理がそれほど重要なのでしょうか。その秘密を探ってみましょう。

なぜカーバイドなのか 熱処理 重要?

数回使っただけで摩耗してしまうドリルビットを使うことを想像してみてほしい。イライラしますよね?超硬熱処理は、超硬工具や部品の硬度と寿命を向上させることで、このような事態を防ぎます。これが重要な理由です:

- 強化された硬度 - 適切な熱処理は超硬材料を強化し、摩耗や変形に対する耐性を高める。

- 耐久性の向上 - 処理されたカーバイドは、極端な温度や過酷な条件に耐えることができ、航空宇宙、自動車、機械加工用途に最適です。

- 切断性能の向上 - 熱処理された超硬合金を使用した切削工具は、切れ味の維持と効率に優れています。

- 脆さの低減 - 適切な熱処理を行わないと、炭化物はもろくなりすぎ、早期破損につながる。

超硬合金熱処理プロセスの種類

1.焼結

焼結は、炭化物粉末を融点以下に加熱して粒子同士を結合させる一般的なプロセスです。これにより、密度、硬度、全体的な機械的特性が向上します。

2.浸炭

浸炭は、高温でカーバイド組織に炭素を導入し、強靭なコアを維持しながら表面硬度を高めます。切削工具や耐摩耗部品に最適。

3.窒化

窒化処理により、炭化物表面に窒素が注入され、硬い窒化層が形成され、耐摩耗性と耐酸化性が大幅に向上する。

4.アニーリング

焼きなましは、超硬材料の内部応力を緩和し、延性を向上させ、脆性を低減するために使用される。

5.焼き入れと焼き戻し

このプロセスでは、急速冷却(焼き入れ)の後に再加熱(焼き戻し)を行い、炭化物粒組織を微細化して靭性と強度を最適化する。

6.プラズマ熱処理

プラズマ熱処理は、イオン化したガスを用いて超硬合金の硬度と表面特性を向上させるもので、高精度工具によく適用される。

7.真空熱処理

この方法では、酸化のリスクを取り除くことができる。 熱処理 を真空チャンバー内に設置し、超硬材料の純度と強度を最大限に高めています。

超硬合金の熱処理による性能向上とは?

| パフォーマンス・ファクター | 熱処理の利点 |

|---|---|

| 硬度 | 表面硬度を大幅に向上 |

| 耐摩耗性 | 磨耗と損傷を減らし、寿命を延ばす |

| タフネス | もろさやひび割れを防ぐ |

| 耐食性 | 耐酸化性の向上 |

| 加工性 | 工具の切れ味と効率を高める |

| 耐熱性 | 極端な動作温度に耐える |

超硬合金の一般的な問題と解決策 熱処理

| 問題 | 原因 | ソリューション |

|---|---|---|

| クラッキング | 急速冷却 | 管理焼入れを使用する |

| 脆さ | オーバーヒート | 加熱温度の最適化 |

| ワーピング | 不均一な熱分布 | 均一に熱を加える |

| 表面酸化 | 空気への暴露 | 真空熱処理の実施 |

| タフネスの低下 | 不適切な焼き戻し | 焼き戻しサイクルの調整 |

適切な超硬熱処理プロセスを選択するには?

適切な熱処理プロセスの選択は、用途と要求される材料特性によって異なります。ここでは、考慮すべき点を説明します:

- 応募資格 - 高衝撃工具には、焼き戻しおよび焼き入れが最適である。耐摩耗性には窒化が理想的です。

- 素材構成 - 炭化物粉末の中には、特定の処理(例えば、焼結にはWC、窒化にはTiC)によく反応するものがある。

- 動作条件 - 温度暴露、腐食リスク、機械的ストレスなどの要因を考慮する。

- コストに関する考察 - 真空処理は高価だが酸化を防ぐ。伝統的な方法は費用対効果が高いが、取り扱いに注意が必要だ。

超硬熱処理の将来動向

超硬熱処理の未来は、技術の進歩とともに進化しています。その次がここにある:

- AI制御熱処理 - 高度な自動化とAIが、熱処理の精度と一貫性を最適化します。

- ナノコーティングの強化 - ナノコーティングと熱処理を組み合わせることで、超硬合金の性能が向上する。

- 持続可能な熱処理 - エネルギー消費と排出を削減した環境に優しいプロセスが人気を集めている。

- ハイブリッド・プロセス - プラズマ窒化のような技術を真空と組み合わせる 熱処理 耐久性と効率の両方を高める。

よくあるご質問

| 質問 | 回答 |

|---|---|

| 耐摩耗性に最適な超硬合金の熱処理とは? | 窒化と浸炭は優れた耐摩耗性を提供する。 |

| 超硬工具は家庭で熱処理できますか? | いや、精度を上げるには専用の器具が必要だ。 |

| 超硬合金の熱処理にかかる時間は? | 方法にもよるが、数時間から数日かかることもある。 |

| 熱処理は超硬合金を脆くするのか? | 適切な焼き戻しを行えば、靭性は保たれる。 |

| 真空熱処理はコストに見合うか? | はい、酸化を防ぎ、カーバイドの純度を向上させます。 |

| 超硬合金の熱処理は元に戻せるのか? | いや、一度熱処理をすれば、その変化は永久的なものだ。 |