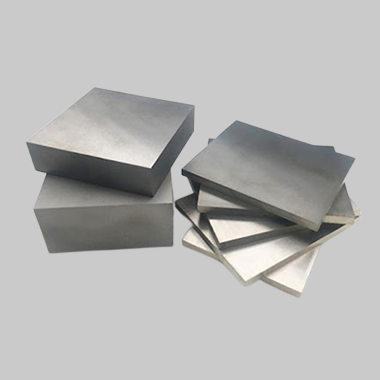

精密工学と製造業の世界では、わずかな誤差が重大な結果をもたらすことがある。そこで カスタムサイズ カーバイド シムプレート は、幅広い用途で比類のない精度と耐久性を提供します。これらの薄く、丹念に作られたプレートは、正確なアライメントを達成し、摩耗を補正し、厳しい環境下で最適なパフォーマンスを確保するために不可欠です。

この包括的なガイドでは、カスタムサイズの超硬シムプレートの世界を掘り下げ、その特性、用途、利点、そしてなぜ適切なサプライヤーを選択することがすべての違いを生むのかを探ります。

特注超硬シムプレートとは?

超硬シムプレートは、非常に硬く耐摩耗性に優れた材料である炭化タングステンから作られる精密加工部品です。これらのプレートは、多くの場合、数千分の1インチのような薄い、幅広い厚さで利用可能であり、特定のサイズと形状の要件を満たすためにカスタム製造することができます。

超硬シムプレートの仕組み:精密調整の科学

超硬シムプレートは、2つの部品間に正確な間隔を作ることで機能します。特定の厚さのシムプレートを挿入することで、エンジニアは正確なアライメントを達成したり、製造公差を補正したり、可動部品間のクリアランスを調整したりすることができます。

業界を超えたアプリケーション:精度が最も重要な分野

カスタムサイズの超硬シムプレートは、以下のような様々な産業で使用されています:

- 航空宇宙 航空機のエンジン、タービン、制御システムの正確なアライメントを確保。

- 自動車: バルブのクリアランス、ベアリングの公差、その他の重要な部品の調整。

- 製造: 精密なアライメントと公差を達成するために、工具、固定具、機械製造に使用される。

- 医療機器 手術器具、インプラント、診断機器に正確な間隔を作る。

- エネルギー生産: タービン、ポンプ、その他の機器に使用し、最適なクリアランスと性能を維持する。

超硬シムプレートの特性:詳しく見る

| 特徴 | 説明 |

|---|---|

| 素材 | 一般的に炭化タングステンは、その卓越した硬度と耐摩耗性で知られている。 |

| 厚さ | 幅広い厚みがあり、0.0005インチ(0.0127mm)以下のものもある。 |

| 表面仕上げ | 特定の表面粗さ要件を達成するために、研削、ラップ、研磨が可能。 |

| 平坦性 | 極めて平坦で平行な表面は、正確なアライメントと均一な荷重分布を保証します。 |

| 精度 | 多くの場合、±0.0001インチ(0.00254mm)以内の厳しい公差で製造される。 |

表1:超硬シムプレートの主要特性

超硬シムプレート使用の利点:高精度を選ぶ理由

- 卓越した耐久性: 超硬合金固有の硬度と耐摩耗性により、過酷な環境下でも性能が長持ちします。

- 正確なアラインメント: 薄い特注サイズのプレートは、装置の最適な機能を実現するために不可欠な、極めて精密な調整を可能にします。

- 寿命が延びる: シムは摩耗を均等に分散させ、コンポーネントの寿命を延ばし、メンテナンスコストを削減するのに役立つ。

- 汎用性がある: さまざまなサイズ、形状、厚みがあり、多様な用途に対応。

カスタムサイズの超硬シムプレートを製造:精密工学の粋

特注サイズの超硬シムプレートの製造には、以下のような一連の特殊加工工程が含まれる:

- 素材の選択: アプリケーションの特定の要件に基づいて、適切なグレードのタングステンカーバイドを選択します。

- ブランキング: 超硬材料を最終寸法よりわずかに大きい粗ブランクに切断する。

- 焼結: ブランクを加圧下で高温に加熱してカーバイド粒子を結合させ、強固で緻密な材料を作る。

- 研磨: 精密研削盤を使用し、目的の厚みと表面仕上げを実現する。

- ラッピング: 表面の平坦度と平行度を極めて厳しい公差でさらに磨き上げる。

- 検査だ: 厳格な品質管理チェックにより、各シムプレートは指定された寸法と表面仕上げの要件を満たしています。

超硬シムプレートの種類:選択肢を探る

- 超硬ソリッドシムプレート: 硬度と耐摩耗性に優れた超硬合金製。

- 超硬シムプレート: 安価な基材に超硬チップをろう付けし、特定のポイントに耐摩耗性を必要とする用途に費用対効果の高いソリューションを提供。

市場動向:高まる精密さへの要求

超硬シムプレートの世界市場は、以下のような要因によって着実な成長を遂げている:

- 自動化の進展: 自動化された製造工程では、正確なアライメントと公差が要求されるため、高品質のシムプレートが必要となります。

- 厳しい業界基準: 航空宇宙や医療機器のような業界では、品質や安全性に関する規制が厳しく、超硬シムプレートのような信頼性と耐久性に優れた部品の使用が求められます。

- 効率を重視する: カスタムサイズのシムプレートは、機器の性能を最適化し、ダウンタイムを減らし、部品の寿命を延ばし、全体的な運用効率に貢献します。

サプライヤーの比較最適なサプライヤーを見つける

| サプライヤー | 所在地 | 価格帯(1個あたり、概算) | 特産品 |

|---|---|---|---|

| TRUER | グローバル | $10~$50+(サイズ、材質、複雑さによる) | 幅広い素材とサイズ、ラピッドプロトタイピング、カスタムソリューション |

| ケナメタル | 米国 | $15 – $60+ | 高性能コーティング、複雑な形状 |

| サンドビック・コロマント | スウェーデン | $20 – $75+ | 先進素材、用途に特化したソリューション |

| ISCツール | 米国 | $12 – $55+ | 標準およびカスタムサイズ、短納期 |

表2:超硬シムプレートサプライヤーの比較

メリットとデメリット:長所と短所を比較する

| メリット | デメリット |

|---|---|

| 高精度 | 他の素材に比べ高コスト |

| 優れた耐久性 | 限られた柔軟性 |

| 幅広い用途 | 衝撃でもろくなることがある |

表3:超硬シムプレートの長所と短所

関連コンポーネント精密ツールキットの拡張

- 超硬磨耗プレート: 摩耗や磨耗から表面を保護するために使用される、より大きく厚いプレート。

- 超硬スペーサー: 部品と部品の間に正確な間隔を提供し、組立品によく使用される。

- 超硬ブッシュ: 回転用途で摩擦や摩耗を減らすために使用される円筒形の部品。

カスタムサイズの超硬シムプレートにTRUERを選ぶ理由

- 妥協のない品質: 当社では、最高品質の超硬素材のみを使用し、製造工程全体にわたって厳格な品質管理対策を採用しています。

- 精密工学: 最新鋭の設備と経験豊富なエンジニアが、正確な寸法と厳しい公差を保証します。

- カスタマイズの専門家: 専門分野 特注サイズのシムプレートお客様と密接に協力し、お客様独自の仕様に対応します。

- 競争力のある価格設定: 私たちは競争力のある価格を提供し、お客様の投資に対して最高の価値を提供するよう努めています。

- 卓越したカスタマーサービス: 私たちの専門チームは、お客様の経験を通じて、迅速で知識豊富なサポートを提供することをお約束します。

よくある質問超硬シムプレートに関するご質問にお答えします。

1.最も薄い超硬シムプレートは何ですか?

超硬シムプレートは驚くほど薄い公差で製造することが可能で、特定の要件によっては0.0005インチ(0.0127mm)、あるいはそれよりも薄くなることもよくあります。

2.自分の用途に合ったシムプレートの厚さはどのように決めればよいですか?

理想的な厚さを決定するには、希望するクリアランス、相手部品の製造公差、予想される摩耗などの要素を考慮する必要があります。技術専門家に相談するか、専用の測定ツールを使用することで、最適なシムプレートの厚さを決定することができます。

3.超硬シムプレートは高温環境で使用できますか?

はい、超硬材料は優れた耐熱性を示し、高温に耐えることができます。しかし、具体的な限界温度は、使用する超硬合金のグレードによって異なります。

4.特注サイズの超硬シムプレートの一般的なリードタイムを教えてください。

リードタイムは、注文サイズ、複雑さ、現在の生産能力などの要因によって異なります。しかし、多くのサプライヤーは競争力のあるリードタイムを提供するよう努力しており、数日から数週間程度であることが多い。

5.特注サイズの超硬シムプレートの見積もり依頼方法は?

ほとんどのサプライヤーは、見積もりを依頼するためのオンラインフォームや連絡先を提供しています。材料、寸法、公差、数量などの詳細な仕様を提供することで、正確でタイムリーな見積もりが可能になります。