超硬合金とCNCマシンとは?

機械加工の世界に飛び込むと、おそらく2つの重要な用語に出くわすだろう: 超硬工具 そして CNCマシン.機械加工の縁の下の力持ちと称される超硬合金は、炭化タングステン粒子と金属バインダー(通常はコバルト)を組み合わせた複合材料です。非常に高い硬度と耐熱性、耐久性で知られ、工業用途には欠かせない。タングステンカーバイドは、切削工具のヘビー級チャンピオンであり、近代的な機械加工の熱と圧力に十分に耐えることができます。

今やCNCマシン(Computer Numerical Controlの略)は、精密製造の技術的バックボーンとなっている。これらの機械は、複雑な切断、穴あけ、成形作業を驚くべき精度で行うようにプログラムされている。金属、プラスチック、複合材などの強靭な素材から複雑なデザインを生み出す能力を備えたロボット彫刻家を想像してみてほしい。超硬工具とCNCマシンは共に、現代の製造業を円滑に運営するパワーデュオを形成しています。

なぜ使うのか 超硬工具 CNCマシンで?

なぜ超硬合金はCNC加工においてこれほど重要なのでしょうか?それは簡単です。超硬工具は、他の材料が不得意とする加工で威力を発揮します。ここでは、超硬工具が最良の選択である理由を説明します:

- 卓越した硬度と耐摩耗性: 超硬合金は、ダイヤモンドに次ぐ硬度を誇ります。そのため、ステンレス鋼、チタン、硬化合金のような強靭な材料の切断に最適です。

- 高い耐熱性: CNC加工はかなりの熱を発生する。超硬工具は、高温下でも切れ味と構造的完全性を維持します。

- 長い工具寿命: 高速度鋼(HSS)や他の材料と比較して、超硬工具は大幅に長持ちし、ダウンタイムと工具コストを削減します。

- 優れた表面仕上げ: 超硬合金の精度は、より滑らかな切断を可能にし、その結果、表面仕上げが良くなり、二次加工の必要性が少なくなります。

CNCマシンで超硬工具を使用することは、単に仕事をこなすことではなく、より良く、より速く、より効率的に行うことです。

CNC用超硬工具の種類

| ツールタイプ | 説明 | アプリケーション |

|---|---|---|

| エンドミル | プロファイリング、スロッティング、コンタリングに使用される多目的切削工具。 | 様々な材料のフライス加工。 |

| ドリルビット | たわみを最小限に抑えた精密な穴あけ用。 | スチール、アルミニウム、複合材への穴あけ。 |

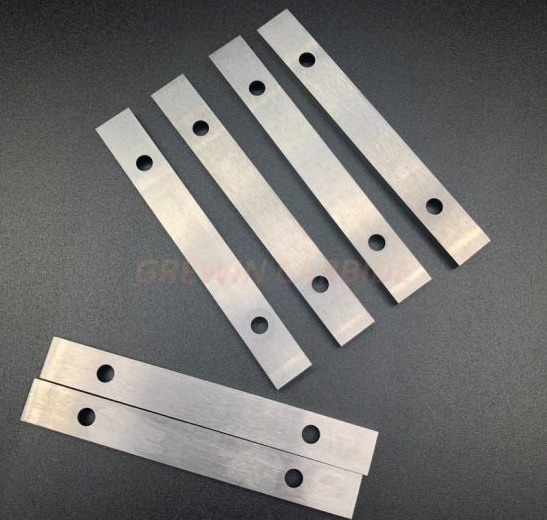

| インサートツール | 交換可能な超硬チップをツールホルダに取り付けて切削を行う。 | 旋盤加工、フライス加工、中ぐり加工。 |

| リーマー | ドリル穴の精密仕上げを行う。 | 穴径の厳しい公差を達成。 |

| ボーリング・バー | 既存の穴を拡大または改良するために使用する。 | 旋盤やフライス盤での内面切削。 |

| スレッド・ミルズ | タッピングの必要なく、材料にねじ山を形成。 | 硬い素材のねじ切り。 |

| 面取り工具 | 部品のエッジを面取りしたり、バリを除去します。 | バリ取りと仕上げ加工。 |

| ボールノーズカッター | 3D輪郭加工や複雑な形状の加工に最適。 | 金型におけるツールパス。 |

| フェイス・ミルズ | 大きな平面での高速材料除去に使用。 | CNCフライス加工における表面仕上げ。 |

| 溝入れ工具 | 部品に溝やスロットを切るために特別に設計されています。 | 自動車および航空宇宙機械加工。 |

CNCマシンに適した超硬工具の選び方

完璧な超硬工具を選ぶには、一長一短があるわけではありません。それは、正しい靴を選ぶようなものです。ここでは、考慮すべきいくつかの要素をご紹介します:

- 加工される素材: 異なる工具は、異なる材料に最適化されている。例えば、アルミニウム用に設計された工具は、焼き入れ鋼ではうまく機能しないことがある。

- オペレーションのタイプ ドリル加工、フライス加工、旋盤加工。それぞれの加工には、特有の工具形状とコーティングが要求されます。

- 工具コーティング: 窒化チタン(TiN)や窒化アルミニウムチタン(AlTiN)のようなコーティングは、摩耗や熱の蓄積を減らすことで性能を高めることができます。

- マシンの互換性: 工具のサイズとシャンクがCNCマシンの仕様に合っていることを確認してください。

- 切断パラメータ: 工具を選ぶ際には、送り速度、切削速度、切り込み深さを考慮する。

賢く選択することは、工具交換の回数を減らし、精度を高め、コストを削減することを意味する。

メンテナンス 超硬工具

超硬工具の性能を最大限に引き出すには、定期的なメンテナンスが重要です。大切に扱えば、最高のパフォーマンスで報いてくれるはずです。その方法をご紹介しましょう:

- 道具を清潔に保つ: 使用後は、ゴミや付着物を取り除くこと。

- 損傷がないか点検すること: 欠け、ひび割れ、刃先のくすみがないか。破損した工具は速やかに交換する。

- 適切に保管すること: 偶発的な損傷を避けるために、指定のラックまたはホルダーを使用してください。

- 工具の摩耗を監視する: 工具寿命管理システムを使用するか、摩耗インジケータを手動でチェックする。

- 必要に応じて研ぐ: 超硬工具の中には、寿命を延ばすために再研磨できるものもある。

超硬工具とCNCマシンの磨耗を減らす実践的なヒント

| チップ | 説明 |

|---|---|

| 切削パラメータの最適化 | 使用する材料と工具に適した速度と送りを使用すること。 |

| クーラントの使用 | 熱の蓄積を抑え、工具の寿命を延ばすために、切削油剤を塗布する。 |

| 過負荷を避ける | 早期故障を避けるため、工具の定格能力を超えて無理をさせないこと。 |

| 定期的な機械校正 | CNCマシンが正確な操作のために正確にキャリブレーションされていることを確認してください。 |

| 高品質の素材を選ぶ | 高品質の原材料を使用し、不純物による工具の摩耗を最小限に抑える。 |

| 適切なツールホルダーを採用する | 工具をしっかりと固定することで、振動を抑え、切削精度を向上させる。 |

超硬マシンとCNCマシンを購入する際の注意点

投資 超硬工具 とCNCマシンの選択は、重要な決断です。以下は、その留意点である:

- 質の問題: 常に実績のある信頼できるメーカーを優先する。

- 素材の互換性: 機械と工具が、作業する素材に合っていることを確認する。

- メンテナンスのしやすさ: メンテナンスが容易な機械や工具は、時間とコストを節約する。

- カスタマイズ・オプション: さまざまな用途に柔軟に対応できる工具や機械を探す。

- 予算とROI: イニシャルコストと、効率や耐久性といった長期的なメリットのバランスをとる。

超硬マシンとCNCマシンの利点と限界

| アスペクト | 超硬工具 | CNCマシン |

|---|---|---|

| メリット | 硬度、耐熱性、長寿命 | 精度、汎用性、効率性 |

| 制限事項 | コストが高く、極端な力が加わると脆くなる | 初期費用、熟練したオペレーターが必要 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬工具がハイス工具より優れているのはなぜですか? | 超硬工具は硬く、長持ちし、高温にも対応する。 |

| 超硬工具は削れますか? | 確かに多くの超硬工具は研ぎ直しが可能だが、それには特別な器具が必要だ。 |

| CNCマシンは中小企業に適しているか? | もちろんコンパクトなCNCモデルは、小規模なオペレーションに大きな価値を提供します。 |

| 正しいCNCマシンの選び方は? | モデルを選ぶ際には、素材、生産量、予算を考慮してください。 |

| 超硬工具はどのような材料を切削できますか? | 金属、プラスチック、複合材、さらにはセラミックも切断できる。 |