はじめに

カーバイド ストリップは、その卓越した硬度、耐摩耗性、耐久性により、様々な産業用途に不可欠なものである。しかし、その性能や寿命は材料特性だけに依存するのではなく、形状や設計にも大きく影響されます。この詳細なブログでは、超硬ストリップのさまざまな形状や設計上の特徴が、その性能や耐久性にどのような影響を及ぼすかについて掘り下げていきます。これらの要因を理解することで、お客様の業務における超硬ストリップの使用を最適化するために、十分な情報に基づいた決定を下すことができます。

超硬ストリップにおける形状の重要性

1.エッジ形状

プロパティ

- シャープネス:切断効率を決定します。

- 強さ:チッピングや破損に対する耐性に影響する。

- 耐摩耗性:ストリップの寿命に影響する。

インパクト:超硬ストリップのエッジ形状は、切断、削り取り、成形などの用途で非常に重要です。エッジが鋭利であればあるほど、よりきれいな切れ味と高い精度が得られ、機械加工や木工などの作業に不可欠です。しかし、鋭利なエッジはチッピングを起こしやすく、磨耗が早まる可能性があります。逆に、丸みを帯びたエッジは耐久性と強度が高く、耐衝撃性が重要なヘビーデューティ用途に適している。

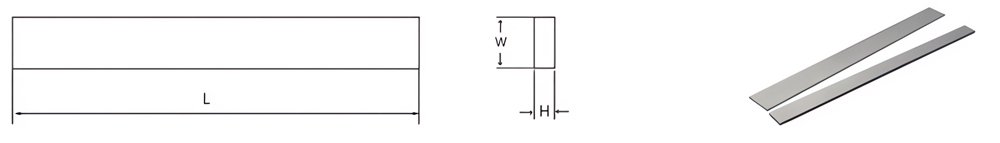

2.厚みと幅

プロパティ

- 剛性:より厚いストリップは、より高いサポートと安定性を提供します。

- 柔軟性:より薄いストリップは、より複雑な形状や表面に適応することができます。

- 放熱:より幅の広いストリップは、より効果的に熱を放散することができる。

インパクト:超硬ストリップの厚さと幅は、その剛性と柔軟性に影響します。厚く幅の広いストリップは剛性が高く、変形することなく高荷重に耐えることができるため、重荷重用途に最適です。一方、薄いストリップは柔軟性が高く、複雑な形状や細部の加工が必要な用途に適しています。さらに、幅の広いストリップは放熱性に優れ、高速動作時の熱損傷のリスクを低減する。

3.長さ

プロパティ

- カバレッジ:長いストリップは、より広い面積をカバーし、頻繁な交換の必要性を低減します。

- サポート:長いストリップは、大型部品のサポートに適している。

インパクト:超硬ストリップの長さは、その被覆範囲とサポート能力を決定します。ストリップが長いほど広い面積をカバーできるため、フライス加工やプレーニング加工など、広範囲の表面接触が必要な用途に有利です。しかし、ストリップが長いと、特に狭い場所での取り扱いと取り付けが難しくなります。

4.表面仕上げ

プロパティ

- 滑らかさ:摩擦と摩耗率に影響する。

- コーティング適合性:ストリップが保護コーティングをどの程度保持できるかを決定する。

インパクト:超硬ストリップの表面仕上げは、その性能に重要な役割を果たします。より滑らかな表面は摩擦を減らし、切削効率を高め、摩耗を減らすことができます。さらに、仕上げの良い表面は、保護コーティングとの密着性を高め、耐摩耗性と耐腐食性を向上させることで、ストリップの寿命をさらに延ばします。

デザインの特徴とその効果

1.面取りエッジ

プロパティ

- 瓦礫撤去:切り屑や破片の除去を容易にする。

- 損害防止:エッジ・チッピングのリスクを低減。

インパクト:超硬ストリップの面取りエッジは、切り屑の排出を促進し、エッジ損傷のリスクを低減することで、性能を向上させるように設計されています。この設計は、フライス加工やドリル加工など、切り屑の効率的な排出が目詰まりを防ぎ、スムーズな作業を実現する上で重要な用途で特に役立ちます。

2.強化コーナー

プロパティ

- 強さ:破損しやすい箇所の耐破損性を高める。

- 耐久性:全体的な寿命を延ばす。

インパクト:強化コーナーは、超硬ストリップの最も脆弱な部分にさらなる強度を提供します。この設計は、コーナーが破損したり欠けたりしやすい鉱業や重機のような、強い衝撃や応力を伴う用途には極めて重要です。

3.溝または鋸歯状のエッジ

プロパティ

- グリップ:ストリップのグリップ力を向上させる。

- 切断効率:ストリップの切断能力を高める。

インパクト:溝付きまたは鋸歯状のエッジは、特定の用途における超硬ストリップの性能を大幅に向上させます。これらの設計特性により、ストリップの材料に対するグリップ力が向上し、鋸引きや研磨材の切断などの作業に最適です。また、セレーションにより切削ポイントが追加されるため、作業効率が向上し、切削に必要な力が軽減されます。

4.テーパーデザイン

プロパティ

- 精密:より正確なコントロールとカッティングが可能。

- 柔軟性:様々な形状や角度に対応。

インパクト:超硬ストリップのテーパーデザインは、細かい作業や複雑な切断作業に不可欠な、より優れた制御性と精度を提供します。この設計により、ストリップはさまざまな形状や角度に適応しやすくなり、繊細な木工加工から精密機械加工まで、幅広い用途に使用できます。

5.多層構造

プロパティ

- 強さ:全体的な構造的完全性を高める。

- 耐摩耗性:多層的な摩耗保護を提供。

インパクト:超硬合金ストリップの多層構造は、優れた性能と耐久性を提供します。各層は、強度、耐摩耗性、熱安定性の向上など、特定の利点をもたらすように設計することができます。この設計は、単層ストリップでは摩耗が早すぎるような高摩耗用途で特に有利です。

デザイン機能の比較分析

さまざまな設計上の特徴が超硬ストリップの性能と耐久性にどのような影響を与えるかをよりよく理解するために、表形式で主要特性を比較してみましょう。

| デザイン特集 | 主要物件 | 主なメリット | 代表的なアプリケーション |

|---|---|---|---|

| 面取りエッジ | 瓦礫撤去、被害防止 | エッジのチッピングを低減し、チップの除去を容易にします。 | フライス加工、ドリル加工 |

| 強化コーナー | 強度、耐久性 | 破損しにくく、寿命が延びる | 鉱業、重機械 |

| 溝付き/鋸歯状エッジ | グリップ、切断効率 | グリップを向上させ、切れ味を高める | のこぎり、研磨材の切断 |

| テーパーデザイン | 精度、柔軟性 | 正確なコントロールを提供し、様々な形状に適応 | 精密木工、精密機械加工 |

| 多層構造 | 強度、耐摩耗性 | 構造的完全性を高め、摩耗保護を提供 | 高摩耗用途、重作業 |

超硬ストリップ設計の革新

超硬ストリップの設計分野は絶えず進化しており、性能と耐久性の向上を目指した新たな技術革新が行われています。最近の進歩には次のようなものがある:

- 先進コーティング技術:ダイヤモンドライクカーボン(DLC)や窒化チタン(TiN)などのコーティングを開発し、耐摩耗性を向上させ、摩擦を低減。

- ハイブリッド・デザイン:さまざまな形状や設計上の特徴を組み合わせて、特定の用途に合わせた特性を持つ超硬ストリップを作成します。

- スマート素材:センサーとスマート素材の統合により、超硬ストリップの状態と性能をリアルタイムで監視し、予知保全を可能にする。

超硬ストリップのメンテナンスとケア

超硬ストリップの寿命と最適な性能を確保するには、適切なメンテナンスとケアが不可欠です。以下はそのヒントです:

- 定期検査:超硬ストリップに摩耗、損傷、欠けの兆候がないか定期的に点検してください。早期発見により、さらなる劣化を防ぐことができます。

- クリーニング:超硬ストリップの性能に影響を及ぼす可能性のあるゴミや汚染物質の蓄積を防ぐため、超硬ストリップは常に清潔に保ってください。

- シャープニング:定期的に刃先を研ぎ、精度と効率を維持する。超硬合金を傷つけないよう、適切な研ぎ具と研ぎ方を使用すること。

- 適切な保管:腐食や物理的損傷を防ぐため、超硬ストリップは乾燥した涼しい場所に保管してください。保護カバーやケースがある場合は、それを使用してください。

よくあるご質問

Q1: 超硬ストリップのエッジ形状は、その性能にどのような影響を与えますか?

A1: 超硬ストリップのエッジ形状は、切削効率、耐久性、耐チッピング性に直接影響します。エッジが鋭利なほど、きれいな切れ味と高い精度が得られますが、チッピングが発生しやすくなります。丸みを帯びたエッジは、耐久性と強度が高く、重作業用途に適しています。

Q2: なぜ超硬ストリップの厚さと幅が重要なのですか?

A2: 厚みと幅によって、ストリップの剛性、柔軟性、放熱性が決まる。厚く幅の広いストリップは剛性が高く、高荷重に耐えることができるため、重作業に最適です。薄いストリップは複雑な形状にも柔軟に対応し、幅の広いストリップは熱を効果的に放散するため、熱による損傷のリスクを低減します。

Q3: 超硬ストリップの面取りエッジにはどのような利点がありますか?

A3: 面取りされたエッジは、切り屑の排出を容易にし、エッジのチッピングのリスクを低減します。この設計は、フライス加工やドリル加工など、切り屑を効率的に除去して詰まりを防ぎ、スムーズな作業を実現することが重要な用途に有効です。

Q4:多層構造はどのように超硬ストリップの性能を高めるのですか?

A4: 多層構造は、全体的な構造的完全性を高め、多層の摩耗保護を提供します。各層は、強度、耐摩耗性、熱安定性の向上など、特定の利点を提供するように設計することができ、高耐摩耗性や高荷重用途に理想的です。

Q5: 超硬合金ストリップの設計における最近の技術革新にはどのようなものがありますか?

A5: 最近の技術革新には、耐摩耗性を向上させるためのダイヤモンドライクカーボン(DLC)や窒化チタン(TiN)などの高度なコーティング技術、異なる形状や機能を組み合わせたハイブリッド設計、予知保全のためにリアルタイムで性能を監視するためのスマート素材とセンサーの統合などがある。

超硬ストリップを安く買いたいですか?クリックしてください これ.