ジュエリー製作への応用

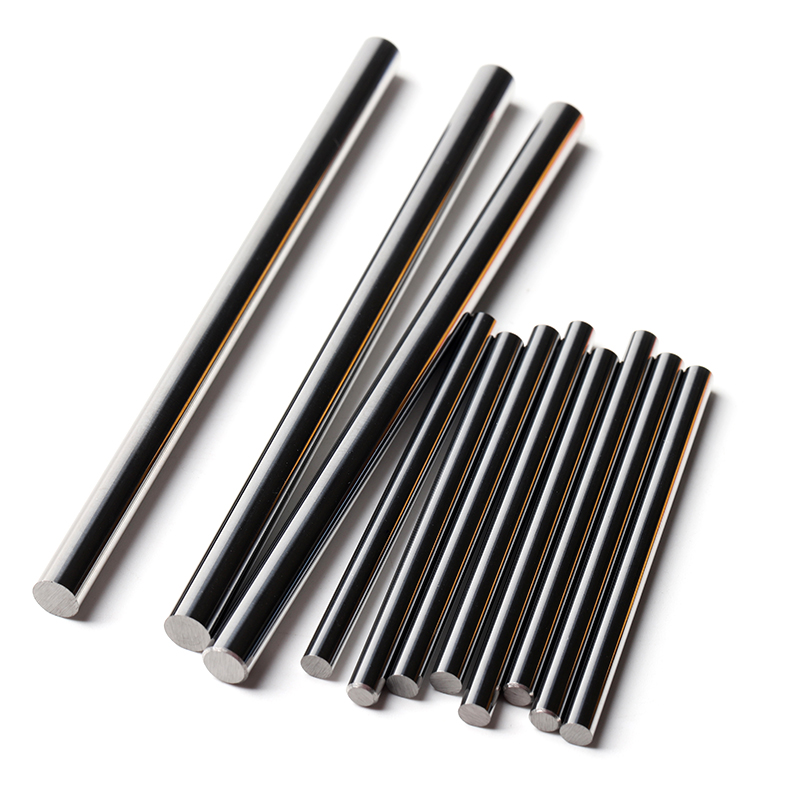

ジュエリーは見た目は繊細で可憐だが、その裏側では道具が使われている。そうではありません。きらびやかなリングや精密にカットされたペンダントを支える秘密の道具は、非常に丈夫な素材で作られている: 超硬棒.ロッド?ジュエリーに?そうです、ただの棒ではありません。タングステン・カーバイドの棒は、その非常識な硬度、エッジの保持力、耐熱性で知られています。

ジュエラー、特に特注品や高級品を扱うジュエラーには、複雑なデザイン、反復作業、極めて高い精度に対応できる工具が求められることが多い。超硬ロッドは、バリ、ドリル、彫刻刀、フライスカッターなどの工具に使用される中心的な材料で、金、プラチナ、さらにはチタンなどの金属の精密成形や彫刻の縁の下の力持ちです。

プラチナ・リングに細かいディテールを彫り込もうとする宝石商を思い浮かべてほしい。スチール製の工具では、数回試しただけで先端が鈍くなってしまう。しかし、超硬工具なら、一度切れば、正しく切れ、長時間切れ続けます。回転工具、CNCマシン、高精度の旋盤など、高級宝飾品工房で使用されています。

超硬対スチール、ダイヤモンド工具:対決

では、ちょっと現実を見てみよう。もしあなたが宝石商なら、次のようなことをするでしょうか? カーバイド, スチールあるいは ダイヤモンド 道具?これがスクープだ。

スチール工具 は昔ながらのクラシックだ。安価で研ぎやすい。しかし、特に硬い金属に対しては、すぐに鈍ってしまう。スチールはバターナイフのようなもので、柔らかい素材には適しているが、硬い素材には不向きだ。

ダイヤモンド工具?これらは工具界のフェラーリだ。超精密で、超硬度で、セラミックや宝石のようなさらに硬い素材にも対応できる。しかし、高価で壊れやすい。ダイヤモンドコーティングされた工具を落とせば、欠けてしまうかもしれない。動きの速いハンズオン・ワークショップには不向きだ。

超硬棒その一方で、彼らはバランスを取っている。彼らは 鋼鉄よりも硬い切れ味はダイヤモンドに匹敵するが、耐久性ははるかに高い。もろくなりにくく、特に日常的な損耗には寛容だ。1ヶ月おきに交換する必要がない工具が欲しいですか?超硬にしましょう。

| 特徴 | スチール工具 | ダイヤモンドコート工具 | 超硬棒工具 |

|---|---|---|---|

| 硬度 | 中程度 | 極めて高い | 非常に高い |

| 耐久性 | 低い | 壊れやすい | 素晴らしい |

| コスト | 低い | 非常に高い | 中~高 |

| 理想的な使用例 | ソフトメタル | ジェムストーン/セラミックス | ハードメタル/精密 |

| シャープニング能力 | 簡単 | 研げない | 工具で研げる |

宝石商の超硬棒の正しい選び方

適切な超硬棒を選ぶには、最初に棚に並んだピカピカの棒を手に取ればいいというわけではありません。宝石商は、いくつかの要素を考慮します:

- ロッド構成:を選ぶ人が多い。 炭化タングステン-コバルト(WC-Co) の組み合わせ。コバルトはバインダーとして働き、強度を増す。

- 粒度:繊細な彫刻作業には細粒の超硬棒が適しており、耐久性や荒削りには粗粒が適している。

- 公差と仕上げ:ミクロン単位が重要な高速アプリケーションでは、高公差の研磨ロッドがより効果的に機能します。

- 工具の互換性:工具によって、必要なロッド径や長さが異なります。ジュエラーは回転工具、ドレメル、CNCアタッチメントに合うロッドをよく探します。

優れた宝石職人は、シェフが包丁を使いこなすように、超硬合金を使いこなす。彼らは仕事に道具を合わせます。

なぜ使うのか 超硬棒 ジュエリーを作る?

簡単な答え? あなたの生活をより快適にしてくれる。

工具が長持ちし、切り口がきれいで、結果が安定している。これが超硬ロッドがもたらすものです。金やプラチナのような高価で繊細な素材を扱う場合、わずかなミスが何百ドルにもなることがあります。超硬工具は、ミスを防ぐ精度を提供します。

さらに、カーバイドは 耐食性.多少湿気の多い作業場に工具を放置していても、錆びたり劣化したりすることはありません。特に、カスタムメイドの仕事の最中に工具の故障を許されない職人的なジュエリー職人にとっては、これは安心につながります。

超硬ロッドはまた、信じられないほど優れている。 用途が広い.結婚指輪にイニシャルを彫ることから、オーダーメイドのメタルペンダントを彫刻することまで、あらゆる目的に対応する超硬工具があります。

炭化タングステンのジュエリーデザインへの応用

今、私たちは芸術と魂の話をしている。職人であるジュエラーは、作品を大量生産しているのではなく、ストーリーを彫刻しているのです。そのためには、手の延長のように反応する道具が必要です。

炭化タングステン が優れているのは、その適応性の高さにある。ジュエラーは次のような用途に使用する:

- マイクロ・エングレービング:美術館のような複雑なデザインに。

- チャンネル設定:宝石を固定する精密な溝。

- 研磨砥石:金属に高級感のある鏡面仕上げを施す。

- カスタムダイスタンピング:唯一無二のシェイプとパターンを創造する。

タングステンカーバイドが優れているのは性能だけではありません。さらに 美的プロセス.道具がぐらついたり、欠けたり、鈍ったりしないことがわかれば、アーティストの流れは妨げられない。

ブティック・ジュエラーの中には、デザインまで手がけるところもある。 超硬ロッドを使用した自作工具カスタム仕様に加工する。それが献身だ。

宝飾用超硬棒用金属粉末トップ10モデル

以下は、製造に使用される一般的な金属粉末モデルのリストである。 超硬棒 ジュエリーを作る道具に適している:

| パウダーモデル | コンポジション・ハイライト | 理想的なアプリケーション | 特筆すべき特徴 |

|---|---|---|---|

| WC-コ 6% | 94% タングステンカーバイド、6% コバルト | 繊細な彫刻、軽いカッティング | 超微粒子、高い耐摩耗性 |

| WC-Co 10% | 90% タングステンカーバイド、10% コバルト | 汎用シェーピング | 強さとタフネスのバランス |

| WC-Ni 12% | 88% WC、12% ニッケルバインダー | 腐食性環境(研磨など) | 高耐食性、非磁性 |

| WC-TiC-Co | WC+炭化チタン+コバルト | 硬質金属の高速切断 | 耐摩耗性と耐熱性の向上 |

| WC-Co 3% UF | 極細粒、3% コバルト | 微細パターンの彫刻 | 優れたエッジ保持力と精度 |

| WC-Co 15% | 粗目、15% コバルト | 荒削りと研磨 | 高い靭性、低い硬度 |

| WC-TaC-Co | 炭化タンタル封入 | 超耐久性の彫刻作業 | 耐衝撃性、プレミアム性能 |

| WC-ZrC-Co | 炭化ジルコニウム、6% コバルト | 精密溝加工 | 熱疲労に対する耐性が向上 |

| WC-CoCr | WC+コバルト・クロム合金 | 高摩耗研磨工具 | 高速に強く、鏡面研磨に適している。 |

| WC-Co HSA | 高強度合金 | メタルエンボス用金型製作 | 優れた耐衝撃性 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬棒は宝飾品製造では何に使われるのですか? | 超硬ロッドは、ジュエリーの金属部品を切断、彫刻、研磨、成形するための工具に使用される。 |

| 超硬工具はダイヤモンドよりも宝飾品作りに適していますか? | ダイヤモンド工具は硬いがもろい。超硬工具は耐久性、切れ味、寿命が長く、破損のリスクも少ない。 |

| 超硬工具は金や銀に使えますか? | もちろんです。超硬工具は、金のような柔らかい金属にも、プラチナやチタンのような硬い金属にも理想的です。 |

| 炭化タングステンはチタンと同じですか? | タングステン・カーバイドはより緻密で硬く、耐摩耗性に優れています。チタンは軽量で耐食性に優れている。 |

| 宝石商は特注の超硬工具を作るのですか? | 職人の中には、自分たちの技術に合わせて超硬工具を作ったり、注文したりする人もいます。 |

| 超硬工具の寿命は? | 適切に使用すれば、超硬工具は、特に細かい作業において、数カ月、あるいは数年使用できる。 |

| カーバイドで環境に優しいオプションはありますか? | リサイクルカーバイドは一般的になりつつあり、持続可能な製造方法を提供するサプライヤーもある。 |

| 超硬合金は宝石のセッティングに使えますか? | はい。超硬工具は、硬い宝石のセッティングに十分な精度があります。 |

| 超硬ロッドの主なバインダーは何ですか? | 通常はコバルトかニッケルで、炭化タングステンの粒をつなぎ合わせる。 |

| 初心者でも超硬工具は使えますか? | 間違いありません!安定した性能を発揮するので、新人ジュエラーが精密な技術を身につけるのに役立ちます。 |