超硬コーティング は、航空宇宙から自動車、製造まで幅広い用途を持つ、材料科学の魅力的な分野である。一般的に炭化タングステンのような硬質材料を用いて作られるこれらのコーティングは、比類のない耐久性、硬度、耐摩耗性を提供します。このガイドでは、炭化物コーティングの世界を深く掘り下げ、その組成、用途、製造方法などを検証します。

超硬コーティングとは?

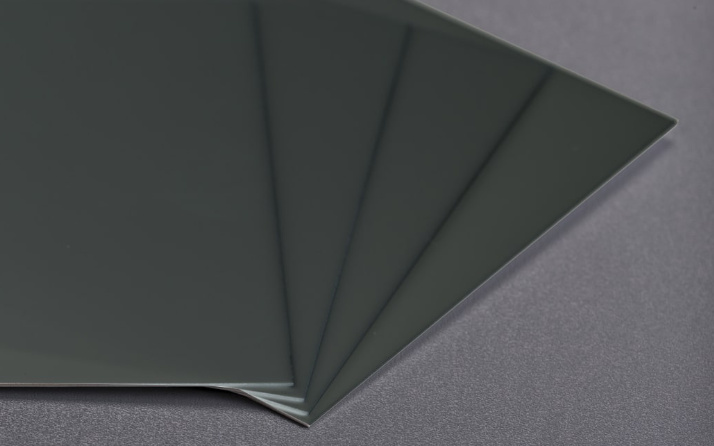

カーバイドコーティングは、非常に硬く耐久性のある材料の薄い層で、多くの場合カーバイドベースの化合物で構成され、様々な基材に塗布されます。これらのコーティングは、工具、部品、機器の機械的特性を向上させ、耐摩耗性、耐腐食性、耐高温性を提供します。

超硬コーティングは、工具や部品が過酷な環境と戦うために身につける鎧と考えてください。超硬コーティングは、効率を向上させ、寿命を延ばし、多くの場合、運用コストを削減します。

種類 超硬コーティング

超硬コーティングの種類は、その組成と用途によって独自の目的を果たします。主な超硬コーティングの種類を表にまとめました。

| コーティングの種類 | 主な構成 | 主な特徴 |

|---|---|---|

| 炭化タングステン(WC) | コバルト中のWC粒子 | 高硬度、優れた耐摩耗性、優れた靭性 |

| 炭化クロム(CrC) | ニッケルまたはコバルトのCrC | 優れた耐食性と耐酸化性 |

| 炭化チタン(TiC) | TiCマトリックス | 高温性能、軽量 |

| 炭化ケイ素(SiC) | SiCセラミック | 卓越した熱安定性、極めて高い硬度 |

| 炭化ホウ素(B4C) | B4Cコンパウンド | 軽量、高い耐摩耗性 |

| 炭化バナジウム(VC) | 鉄鋼基板におけるVC | 耐摺動摩耗性の向上 |

| 炭化ハフニウム(HfC) | HfCセラミックス | 超高温耐性 |

| 炭化モリブデン (Mo2C) | Mo2Cマトリックス | 良好な熱伝導性、耐酸化性 |

| 炭化ニオブ (NbC) | NbC合金 | 靭性と高温安定性を兼ね備えている |

| 炭化ジルコニウム(ZrC) | ZrCセラミックス | 卓越した硬度と耐薬品性 |

超硬コーティングの原材料と組成分析

炭化物コーティングは、主に結合マトリックスに懸濁された金属炭化物粉末で構成されています。原料の選択は要求される特性によって決まります:

- 超硬パウダー: 炭化タングステン、炭化クロム、炭化ケイ素などである。それぞれ、特定の用途に合わせた独自の特性を備えている。

- バインダー コバルト、ニッケル、鉄は一般的なバインダーで、コーティングに延性と靭性を与える。

- 添加物: ホウ素、チタン、バナジウムといった元素は、硬度や耐食性といった特定の特性を高めるために導入することができる。

原材料の品質はコーティングの性能に直接影響する。例えば、高純度のパウダーは欠陥が少なく、耐摩耗性に優れています。

超硬コーティングの用途

超硬コーティングは、過酷な条件にも耐えることができるため、多くの産業で使用されています。ここに、その用途を紹介する詳細な表を示します:

| 産業 | 申し込み | メリット |

|---|---|---|

| 航空宇宙 | ジェットエンジン部品、タービンブレード | 耐高温性、耐摩耗性 |

| 自動車 | ピストンリング、燃料噴射装置、ターボチャージャー | 摩擦の低減、部品寿命の延長 |

| 石油・ガス | ドリルビット、ポンプ部品、パイプライン保護 | 耐食性、過酷な条件下での耐久性 |

| 製造業 | 切削工具、金型 | 工具寿命の向上、精密加工 |

| メディカル | 手術器具、インプラント | 生体適合性、耐摩耗性 |

| エレクトロニクス | 半導体部品、精密機器 | 放熱、耐摩耗性 |

超硬コーティングの製造工程フロー

超硬コーティングの製造には、最適な性能を確保するためにいくつかの重要な工程があります。ここでは、その工程を簡略化してご紹介します:

- パウダーの調製: 高純度のカーバイドパウダーを選び、バインダーと混合し、均一になるように粉砕する。

- 応用技術:

- サーマルスプレー: 高速酸素燃料(HVOF)またはプラズマスプレー法を含む。

- 化学気相成長法(CVD): 真空チャンバー内で薄い炭化物層を蒸着する。

- 物理蒸着(PVD): 蒸着やスパッタリングでコーティングを行う。

- 硬化と焼結: コーティングされた材料は高温に加熱され、固化して層が接着される。

- 仕上げ: 研磨または研削により、所望の表面仕上げと寸法を確保する。

材料特性 超硬コーティング

超硬コーティングのユニークな特性により、超硬コーティングは不可欠なものとなっています。主な材料特性を表にまとめました:

| プロパティ | レンジ |

|---|---|

| 硬度 | 1500 - 3000 HV |

| 密度 | 14.5 - 15.8 g/cm³ |

| 耐摩耗性 | 素晴らしい |

| 耐食性 | 様々(良い~素晴らしい) |

| 熱伝導率 | 60 - 100 W/mK |

| 動作温度範囲 | -200°C ~ 1200°C |

仕様、サイズ、形状、規格

超硬コーティングには、業界の要件を満たすさまざまな仕様があります。以下はその概要表である:

| パラメータ | 詳細 |

|---|---|

| コーティングの厚さ | 10 - 500 µm |

| 基板材料 | スチール、アルミニウム、セラミック |

| 規格遵守 | ASMB653、ISO9001、MIL-C-81769 |

| 対応形状 | 円筒形、平面、複雑な形状 |

超硬コーティングのサプライヤーと価格詳細の選択

安定した品質を確保するためには、適切なサプライヤーを選ぶことが重要です。以下に考慮すべき要素を挙げる:

| ファクター | 詳細 |

|---|---|

| サプライヤーの評判 | 現場での経験、顧客からの評価 |

| 認証 | ISO認証、品質保証 |

| カスタマイズ・オプション | オーダーメイドの組成と厚み |

| 価格 | 1平方メートルあたり$50~$300(複雑さによる |

正しい選択 超硬コーティング

最適な超硬コーティングを選ぶには、いくつかの要素のバランスを取る必要があります。ここに、あなたの決断の指針となる比較表を示します:

| 考察 | オプション | 最適 |

|---|---|---|

| 硬度と靭性の比較 | WC対CrC | 耐摩耗性と腐食性 |

| 温度要件 | SiCとTiCの比較 | 高温対中温 |

| コスト | 炭化ホウ素と炭化タングステンの比較 | 軽量性と耐久性の比較 |

超硬コーティングの利点と限界

| メリット | 制限事項 |

|---|---|

| 卓越した硬度と耐久性 | 高いイニシャルコスト |

| 耐摩耗性、耐熱性、耐腐食性 | 塗布には専用装置が必要 |

| 部品の寿命を延ばす | 特定の形状における柔軟性の制限 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬コーティングとは? | 耐久性を高めるために表面に施される硬い層。 |

| 超硬コーティングはどのように施されるのですか? | 溶射、CVD、PVDなどの技術。 |

| どのような産業で超硬コーティングが使われているのか? | 航空宇宙、自動車、製造業など。 |

| 超硬コーティングは耐食性に優れているか? | 特にクロムや炭化ケイ素のタイプはそうだ。 |

| 超硬コーティングは高価ですか? | コストは様々だが、耐久性があるため長期的な節約になる。 |