超硬ろう付けチップ は、切断、穴あけ、機械加工工程で卓越した性能を発揮する、現代の産業用アプリケーションの要です。この小さくも強力な部品がどのようにして誕生するのか、その用途や最適な部品の選び方について考えたことがある方は、ぜひこのページをご覧ください。退屈な専門用語を使わずに、魅力的で徹底的に詳しい方法で説明しましょう!

超硬ブレージングチップとは?

熱いナイフでバターを切り裂くように、最も堅い金属を切り裂くことができる鋭利な刃の工具を想像してみてください。超硬ろう付けチップは、本質的にそれを実現します!これは、超硬合金製の切削チップで、ろう付けによって工具本体に接合されています。このチップは、比類のない硬度、耐摩耗性、高熱環境での性能で人気があります。

種類 超硬ろう付けチップ

ここでは、超硬ブレージングチップの種類とその特性を分類してご紹介します:

| タイプ | 主な用途 | 代表的な素材 | 主な特徴 |

|---|---|---|---|

| 一般的なカッティングのヒント | 金属と木材の切断 | 炭化タングステン | 高耐久性、多目的 |

| ターニングのヒント | 旋盤とCNCマシン | コバルトおよびニッケル合金 | 優れた耐熱性 |

| 掘削のヒント | 高精度ドリル加工 | 炭化チタン複合材 | 正確でスムーズなパフォーマンス |

| フライス加工のヒント | 重切削加工 | 炭化クロム・ブレンド | 高ストレス下での長寿命 |

| グルービングのヒント | 精密溝加工アプリケーション | タングステン・チタン・カーバイド | 強化されたチップ制御と精度 |

| プランニングのヒント | 金属表面の鉋がけ | 微粒子タングステンカーバイド | 優れた表面仕上げ |

| 退屈なヒント | 深穴ボーリング | サブミクロン炭化タングステン | 卓越した剛性と強度 |

| スレッディングのヒント | 素材へのねじ切り | ニッケルボンド超硬合金 | 一貫したスレッドプロファイル |

| 耐摩耗チップ | 土木鉱山機械 | マルチ超硬複合材 | 高い耐衝撃性と耐摩耗性 |

| 特別なヒント | カスタマイズ・アプリケーション | 超硬合金ブレンド | ニーズに応じた独自の特性 |

原材料と成分分析

超硬ろう付けチップの優れた性能は、その製造に使用される高度な材料によるものです。これらの材料は、特定の産業需要を満たすために細かく調整されています。では、その原材料の構成についてさらに深く掘り下げてみましょう。

- 炭化タングステン(WC): 圧倒的な硬度と強度を誇る超硬チップの主力製品。

- コバルト(Co): バインダーとして使用されるコバルトは、炭化物粒をつなぎ合わせ、靭性を確保する。

- ニッケル(Ni)とクロム(Cr): 耐食性と熱安定性を加える。

- 炭化チタン(TiC): 高速用途での耐摩耗性を向上。

- その他の添加物 靭性、耐酸化性、熱伝導性などの特性を微調整。

超硬ろう付けチップの用途

超硬ブレージングチップの多用途性は驚異的です。ここでは、超硬ブレージングチップが業界を超えてどのように優れているかをご紹介します:

| 産業 | アプリケーション | 主なメリット |

|---|---|---|

| 自動車 | エンジン部品加工、歯車切削 | 精度、スピード、耐久性 |

| 航空宇宙 | ジェットエンジン部品、機体穴あけ加工 | 高い耐熱性と耐摩耗性 |

| 木工 | 木材のシェーピング、プレーニング、カービング | 滑らかな切れ味と長持ちするエッジ |

| 鉱業 | 削岩機、土木工具 | 耐衝撃性と耐摩耗性 |

| 石油・ガス | パイプねじ切り、バルブ加工 | 腐食と高温での取り扱い |

| 金属加工 | 一般機械加工、旋盤作業 | 汎用性と高い仕上がり品質 |

| エレクトロニクス | PCB穴あけ、精密部品切断 | ミクロンレベルの精度 |

製造工程の流れ 超硬ろう付けチップ

超硬ブレージングチップがどのように作られるのか、不思議に思ったことはありませんか?それは、高度な技術と精密なエンジニアリングを駆使した細心のプロセスです。その製造工程をご紹介します:

- パウダーの調製: タングステン、コバルト、その他の粉末を所望の組成にブレンドする。

- 圧縮: パウダーを圧縮して目的の形状にする。

- 焼結: 圧縮されたチップは、所望の密度と硬度を得るために高温で加熱される。

- 研磨: シャープなエッジと指定された寸法を達成するための精密研削。

- ろう付け: チップは、高温合金フィラーを使用したろう付けプロセスで工具本体に取り付けられる。

- 検査とテスト: 厳格な品質管理により、最高の性能を保証する。

- パッケージング: 最後に、チップは出荷と保管のために梱包される。

超硬ろう付けチップの材料特性

| プロパティ | 値の範囲 | 重要性 |

|---|---|---|

| 硬度 | 89-94 HRA | 耐摩耗性を決定する |

| 曲げ強度 | 1500-3000 MPa | 応力下での曲げに対する抵抗力を示す |

| 密度 | 14.5-15.5 g/cm³ | 工具のバランスと重量に影響 |

| 熱伝導率 | 75-125 W/mK | 加工中の熱放散を確保 |

| 弾性係数 | 450-700 GPa | 剛性と剛性を示す |

| 破壊靭性 | 9~13MPa・m¹/²(1MPa・m²あたり | 亀裂伝播に対する抵抗力を示す |

主な特徴構成と特徴

| エレメント | パーセント(%) | 機能性 |

|---|---|---|

| 炭化タングステン | 85-90 | 比類のない硬さで刃先を提供する |

| コバルト | 8-12 | 炭化物粒を結合し、靭性を高める |

| 炭化チタン | 0-3 | 耐摩耗性を高める |

| クロム | 0-1 | 耐食性の向上 |

性能パラメータ硬度、強度、耐摩耗性

| パラメータ | グレードA | グレードB | グレードC |

|---|---|---|---|

| 硬度(HRA) | 92 | 90 | 88 |

| 曲げ強度 (MPa) | 2500 | 2200 | 2000 |

| 耐摩耗性 (mm³) | 高い | ミディアム | 低い |

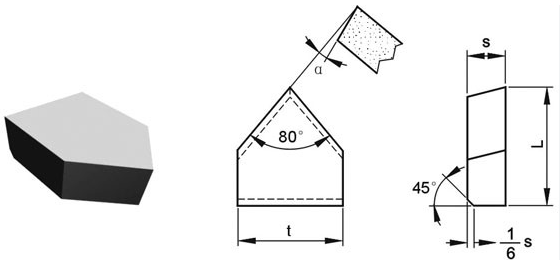

仕様、サイズ、形状、規格

| 仕様 | 利用可能範囲 | 規格 |

|---|---|---|

| 先端寸法 | 10~50mm(L)、2~10mm(T) | ISO 513、ANSI B212.1 |

| シェイプス | ラウンド、スクエア、トライアングル | ISO 1832 |

| 寛容 | ±0.02 mm | DIN 69881 |

サプライヤーと価格詳細

| サプライヤー名 | 地域 | 価格帯(1台あたり) | リードタイム |

|---|---|---|---|

| XYZカーバイド社 | 北米 | $2.00-$5.00 | 2~3週間 |

| グローバルツールパーツ | ヨーロッパ | $1.50-$4.50 | 1~2週間 |

| 精密ハードメタル | アジア | $1.00-$3.50 | 2~4週間 |

正しい選択 超硬ろう付けチップ

| ファクター | 主な検討事項 |

|---|---|

| カットする素材 | 硬い金属と木材のような柔らかい素材 |

| 先端形状 | 用途に応じた形状と角度 |

| 動作条件 | 高熱、スピード、研磨環境 |

| 予算 | コストとパフォーマンスのトレードオフ |

| サプライヤーの評判 | 一貫性と品質保証 |

利点と限界

| メリット | 制限事項 |

|---|---|

| 極めて高い硬度と耐摩耗性 | 高いイニシャルコスト |

| 業界を超えた汎用性 | 極端な衝撃を与えると脆くなる |

| 長い工具寿命とダウンタイムの削減 | 正確なハンドリングが必要 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬ブレージングチップはなぜ効果的なのか? | 硬度、靭性、耐熱性を兼ね備えている。 |

| 超硬チップは再利用できますか? | 再研磨は可能だが、何度も使用すると性能が低下する可能性がある。 |

| 自分のプロジェクトに最適なチップを選ぶには? | 材質、形状、具体的な用途を考慮する。 |

| 超硬チップは高価ですか? | 初期コストは高いが、耐久性に優れているため長期的な節約になる。 |