超硬合金とは何か、なぜ高圧下で威力を発揮するのか?

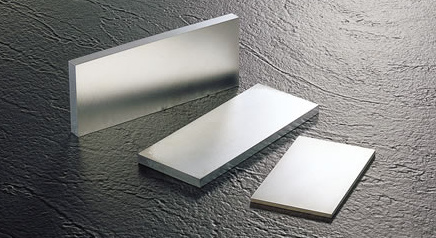

カーバイド は極限環境という点では画期的だ。しかし、何がそれほど特別なのか?汗をかくことなく、非常な圧力に対応できるほど頑丈な素材を想像してみてください。それがカーバイドだ!基本的に、超硬合金は金属炭化物(炭化タングステン、炭化チタン、炭化タンタルなど)をコバルトやニッケルなどの金属バインダーと結合させた複合材料です。

超硬合金を際立たせているのは、その極めて高い硬度と、高圧、高温、腐食条件下でも構造的完全性を維持する能力です。圧力を受けると変形する鋼鉄とは異なり、超硬合金は耐えることができるため、材料の限界に挑む産業にとって最適な選択肢となっています。

主な特性 カーバイド 過酷な条件下で

高圧用途では、超硬合金は欠かせない特性を誇っている:

- 並外れた硬度: 超硬合金はダイヤモンドとほぼ同等の硬度を持ち、極度のストレス下でも耐久性を発揮します。

- 高い圧縮強度: 他の金属とは異なり、超硬合金は変形することなく大きな力に耐えることができる。

- 優れた耐摩耗性: 切断、穴あけ、高摩擦環境に最適。

- 熱安定性: その特性を失うことなく1000℃以上の温度に耐える。

- 耐食性: 過酷な化学環境、特に石油やガスの掘削に不可欠。

高圧環境における超硬合金の用途

超硬合金はその堅牢性から、極度の圧力に直面する産業で選ばれる材料となっています。主な用途をいくつかご紹介しましょう:

石油・ガス掘削

- で使用される。 ドリルビット、ノズル、摩耗部品 高圧の地下条件下で不屈の強さが要求される場所。

航空宇宙工学

- には欠かせない。 タービン部品、切削工具、保護膜 高圧ジェットエンジンの

採鉱とアースドリル

- 砕岩ビット、ドリルインサート、カッティングエッジ 地下掘削の激しい力に耐えられるよう、カーバイドを使用している。

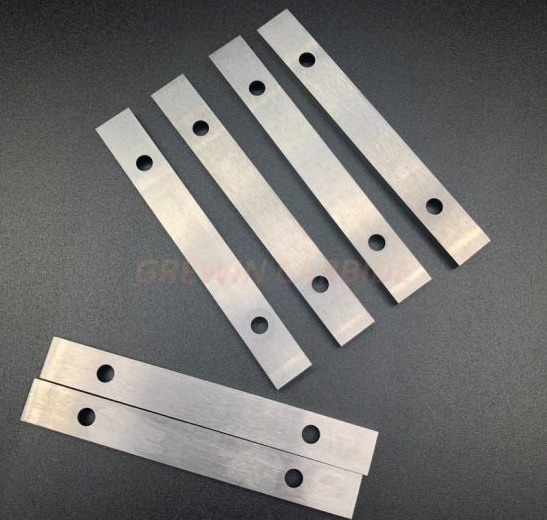

製造・金属加工

- 切削工具、成形ダイ、押出ダイ 炭化物の高い機械的応力下での変形に対する耐性を活用する。

自動車産業

- 高性能エンジンは バルブシート、インジェクター、精密加工ツール 極端な圧力と温度変化に耐える。

正しい選び方 カーバイド アプリケーションのために

| 超硬タイプ | 硬度(HV) | 圧縮強度 (MPa) | 最適 |

|---|---|---|---|

| 炭化タングステン(WC-Co) | 1400-2000 | 4000-6000 | 掘削、採鉱、機械加工 |

| 炭化チタン(TiC) | 1800-2800 | 4500-6000 | 切削工具、航空宇宙用途 |

| 炭化タンタル(TaC) | 2000-3000 | 5000-6500 | 高温環境 |

| 炭化クロム(CrC) | 1200-2000 | 3000-5000 | 耐摩耗コーティング |

| 炭化ニオブ (NbC) | 1800-2800 | 4500-6000 | 遮熱コーティング、切削工具 |

高圧超硬合金開発の将来動向

| トレンド | 説明 |

|---|---|

| ナノ構造カーバイド | ミクロレベルでの強度と耐摩耗性の向上。 |

| ハイブリッドカーバイド | 複数の超硬合金を組み合わせ、最適なパフォーマンスを実現。 |

| 3Dプリント超硬合金 | 特殊な高圧用途向けにカスタマイズ可能な形状。 |

| コーティング技術 | 耐食性と耐摩耗性を向上させる高度なコーティング。 |

| 環境に優しいバインダー | 持続可能な生産のために、コバルトとニッケルの使用を減らす。 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬合金の中で最も強度の高いものは何ですか? | 炭化タングステン(WC)は、硬度と靭性の最高の組み合わせを提供し、広く最強と考えられている。 |

| 超硬合金は圧力で割れるのか? | 超硬合金は驚くほど強い反面、もろい。急激な衝撃を受けると割れることがある。しかし、制御された高圧環境では、ほとんどの金属をしのぐ性能を発揮します。 |

| 超硬合金は鋼鉄と比べてどうですか? | 超硬合金は鋼鉄よりもかなり硬く、耐摩耗性が高いが、もろい。そのため、切削工具や穴あけなどの特定の用途に最適です。 |

| 超硬合金は高価ですか? | 確かに、超硬合金はその優れた特性のため、スチールよりも高価になる傾向があります。しかし、長期的な用途では、その耐久性がコストを相殺することがよくあります。 |

| 超硬合金に最も依存している産業は? | 航空宇宙、石油・ガス、鉱業、製造業、自動車産業は、その比類ない強度と耐久性で超硬合金を頼りにしています。 |