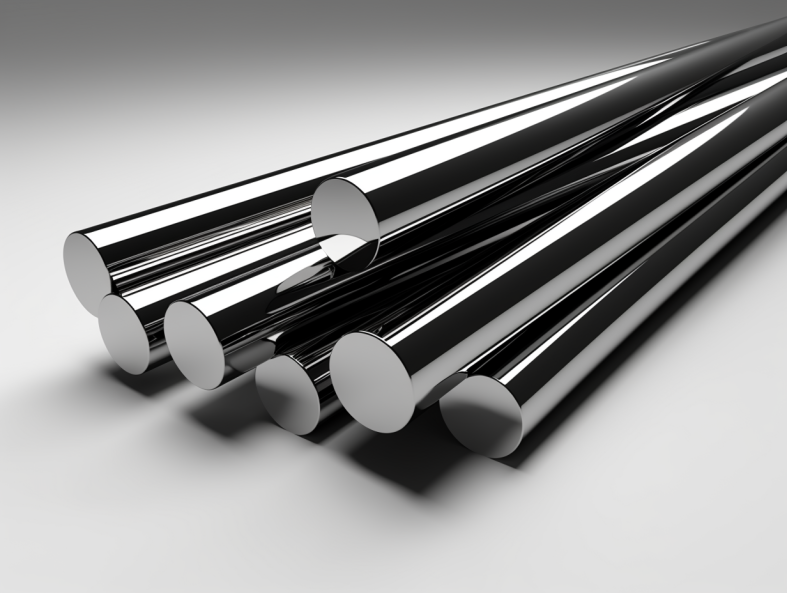

When it comes to industrial tooling and machining applications, 超硬棒 are indispensable. Their pricing, however, can seem like a maze of complexity. From the raw materials to the manufacturing process, several factors influence the cost. If you’re diving into the world of carbide rods, you’re in the right place. Let’s break this down and explore everything about carbide rod pricing, including specifications, applications, and how to make the best choice for your needs.

Understanding Carbide Rods and Their Applications

超硬ロッドとは?

Carbide rods are cylindrical tools made from 炭化タングステン粉 mixed with a binder like cobalt. These materials are sintered under high heat and pressure, creating a hard, durable product with excellent wear resistance. You’ll find carbide rods in industries like aerospace, automotive, and manufacturing for tasks like drilling, cutting, and milling.

Key Factors Influencing 超硬棒価格

Raw Material Composition

The composition of carbide rods plays a significant role in their pricing. Tungsten carbide, the main component, is a rare and expensive material. Adding cobalt, titanium carbide, or other binders increases the cost further.

| 素材 | Composition (%) | Cost Contribution |

|---|---|---|

| 炭化タングステン | 85-95 | 高い |

| コバルト(バインダー) | 5-10 | ミディアム |

| 炭化チタン | 1-3 | 低い |

生産工程の流れ

The production process is another major cost driver. Here’s a simplified breakdown:

- パウダーの準備: Raw tungsten carbide is mixed with cobalt.

- プレス: The mixture is compacted into a rod shape.

- 焼結: High-temperature sintering creates a dense, strong material.

- 仕上げ: Polishing and coating the rod enhance its performance.

Each of these steps requires precision and specialized equipment, adding to the final cost.

Carbide Rod Applications and Cost Dynamics

Carbide rods are used in several industries, each with unique pricing demands:

| 申し込み | Specific Use | Pricing Impact |

|---|---|---|

| 航空宇宙 | Cutting and drilling aircraft components | High (due to quality demands) |

| 自動車 | エンジン部品加工 | ミディアム |

| 製造業 | 汎用工具 | Low to medium |

| エレクトロニクス | Precision drilling in PCB production | 中~高 |

Metal Powder Models and Their Impact on Pricing

Different grades of metal powders affect carbide rod performance and cost. Here’s a look at ten common models:

| パウダーモデル | 構成 | 特徴 | アプリケーション | 価格帯 |

|---|---|---|---|---|

| WC-10Co | 90% WC、10% Co | 高い靭性 | Milling cutters, drills | $$$ |

| WC-12Co | 88% WC、12% Co | 優れた耐摩耗性 | マイニングツール | $$$$ |

| WC-15Co | 85% WC、15% Co | Superior strength | 頑丈な工具 | $$$$ |

| WC-TiC | WC with TiC | 高温耐性 | Aerospace tools | $$$$$ |

| Submicron WC | Ultra-fine WC | 極度の硬度 | 精密工具 | $$$$$ |

| Nano WC | Nano WC | Best wear resistance | エレクトロニクス | $$$$$ |

| WC-コバルト-クロム | WC with Co, Cr | Anti-corrosion | Marine tools | $$$$ |

| WC-Co-TaC | WC with Co, TaC | 優れた熱安定性 | 自動車 | $$$$ |

| WC-Co-Al2O3 | WC with Co, Al2O3 | Improved oxidation resistance | Cutting applications | $$$ |

| WC-ニ | WC with Ni | Enhanced toughness and ductility | Custom tools | $$$$ |

超硬ロッドの材料特性

The quality of carbide rods is evaluated based on properties like hardness, strength, and wear resistance.

| プロパティ | レンジ | 意義 |

|---|---|---|

| 硬度(HRA) | 85-92 | Determines cutting ability |

| 横強度 | 2000-4000 MPa | Measures toughness |

| 耐摩耗性 | 高い | Ensures long tool life |

| 密度 | 14.0-15.5 g/cm³ | Affects weight and usability |

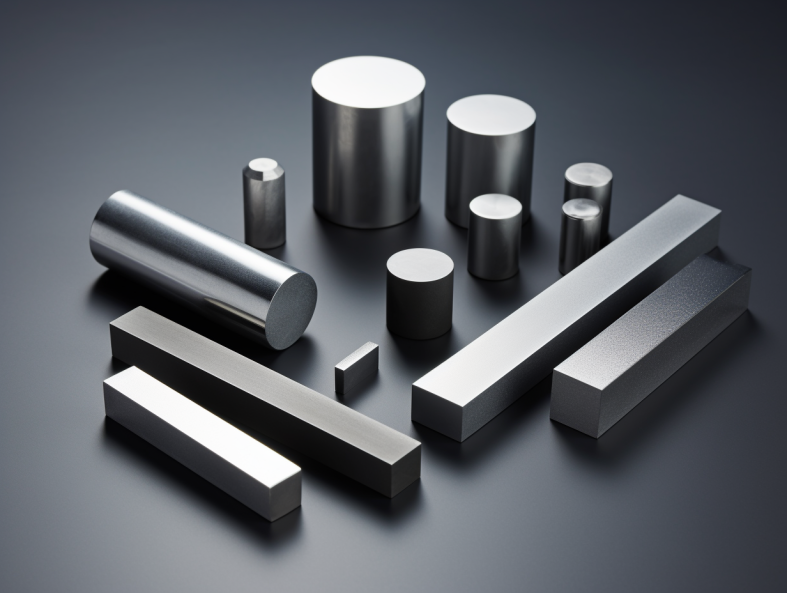

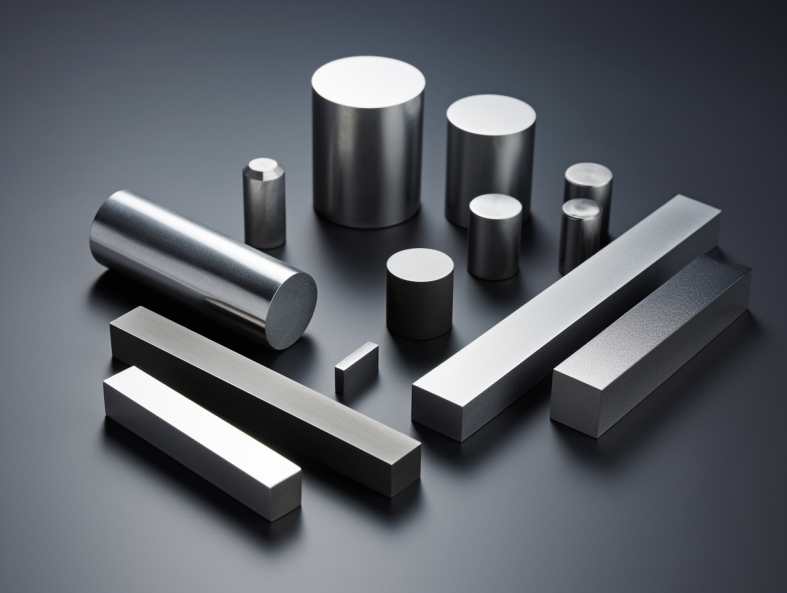

仕様、サイズ、形状、規格

Carbide rods come in a wide range of specifications to suit different applications.

| 仕様 | 詳細 |

|---|---|

| 長さ | 50-330 mm |

| 直径 | 3-40 mm |

| 形状 | Round, rectangular, square |

| 規格 | ISO, ASTM, GB |

サプライヤーと価格詳細

Finding reliable suppliers ensures cost-effective carbide rod procurement.

| サプライヤー | 価格帯(kgあたり) | Delivery Options |

|---|---|---|

| サンドビック | $50-$150 | Worldwide |

| ケナメタル | $60-$180 | Bulk discounts |

| 株洲超硬合金 | $40-$120 | カスタマイズ |

超硬ロッドの利点と限界

| メリット | 制限事項 |

|---|---|

| 卓越した硬度 | Expensive raw materials |

| 高い耐摩耗性 | 機械加工が難しい |

| 優れた熱安定性 | 限られた柔軟性 |

Selecting the Right Carbide Rod

When choosing carbide rods, consider these factors:

| 基準 | 主な検討事項 |

|---|---|

| アプリケーション・タイプ | Aerospace, manufacturing, etc. |

| 素材構成 | High WC content for durability |

| 価格帯 | コストとパフォーマンスのバランス |

よくあるご質問

| 質問 | 回答 |

|---|---|

| なぜ超硬ロッドは高価なのか? | Due to costly raw materials and precision manufacturing |

| Which industries use carbide rods most? | Aerospace, automotive, electronics, manufacturing |

| How do I choose the best carbide rod supplier? | Consider pricing, quality standards, and delivery options |

| Can I customize carbide rod specifications? | Yes, many suppliers offer tailored solutions |

By understanding these factors and comparing options effectively, you’ll be better equipped to navigate the market for carbide rods. Ready to invest in high-quality carbide rods for your next project.