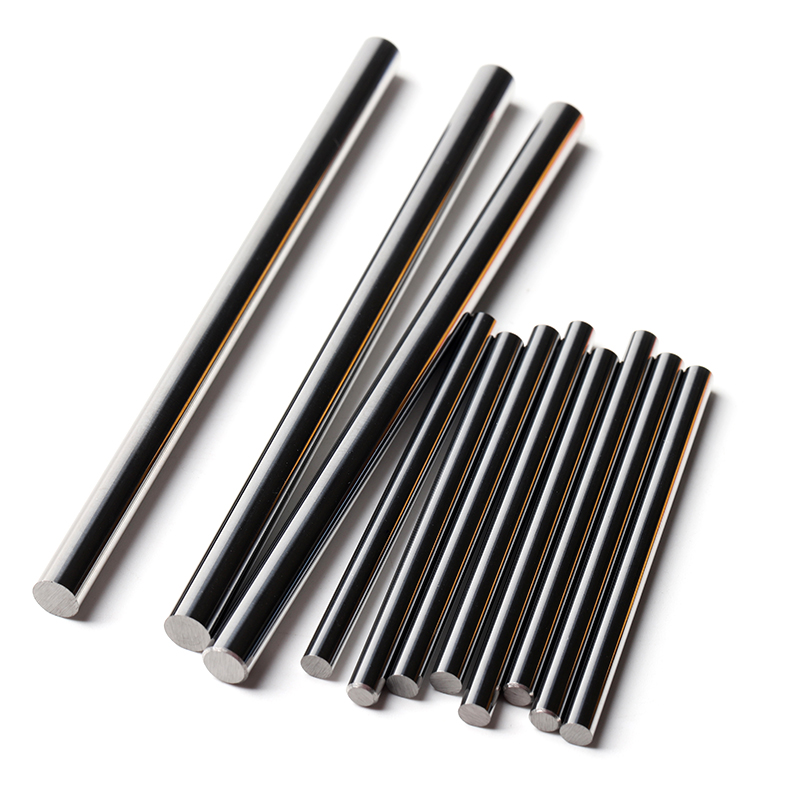

超硬ロッドは、様々な機械加工や工具用途のバックボーンです。精度と耐久性が必要な場合 ストレートクーラントホール超硬ロッド をお勧めします。なぜか?頑丈で耐摩耗性に優れ、過酷な加工条件にも対応できるからです。この魅力的なトピックを深く掘り下げ、このエンジニアリングの驚異を隅々まで探ってみましょう。

ストレートクーラントホール超硬ロッドとは?

超硬ストレートクーラントホールは、主に製造業で使用される高性能工具です。これらのロッドは超硬合金製で、長さ方向にクーラントチャンネルがまっすぐ通っているのが特徴です。この溝により、加工中の効率的な冷却と潤滑が可能になり、工具の摩耗を減らし、性能を向上させます。CNCマシンと切削工具の縁の下の力持ちと考えてください。

種類 ストレートクーラントホール超硬ロッド

| タイプ | 説明 |

|---|---|

| シングルクーラントホールロッド | クーラントフロー用のストレートホールを1つ装備。あまり複雑でない冷却要件に最適。 |

| ダブルクーラントホールロッド | 2つの平行なクーラントホールは、特に高速加工用途において、より優れた冷却効率を保証します。 |

| クーラントホール付きソリッドロッド | 高い構造的完全性と効率的な冷却を両立。強度が重要なヘビーデューティー用途に使用。 |

| ヘリカルクーラントホールロッド | スパイラルチャネルによる冷却強化により、工具のホットスポットを減らし、寿命を延ばします。 |

| カスタム径ロッド | 特殊な加工ニーズに対応するため、さまざまな直径をご用意しています。 |

| マイクロクーラントホールロッド | 精密な冷却を必要とする小規模な機械加工用に設計されています。 |

| ヘビーデューティクーラントロッド | ステンレス鋼やチタンなどの強靭な材料の加工に最適。 |

| コーティング付き超硬棒 | TiN、TiAlN、ダイヤモンドなどの耐摩耗性コーティングを施し、特定の用途における性能を向上。 |

| ISO標準クーラントロッド | サイズと組成に関する国際規格に準拠し、世界の機械との互換性を確保。 |

| カスタム・レングス・ロッド | 独自の運用設定に合わせて、特定の長さに調整。 |

原材料と成分分析

クーラントホール用超硬ストレートロッドの主な材質は次のとおりである。 炭化タングステンタングステンと炭素の化合物。硬度、靭性、耐摩耗性のバランスをとるため、組成はしばしば微調整される。

典型的な構成

| 素材 | パーセント | 目的 |

|---|---|---|

| 炭化タングステン | 85-97% | 高性能工具に不可欠な硬度と耐久性を提供。 |

| コバルト・バインダー | 3-15% | 靭性を高め、タングステンカーバイド粒子の結合を助ける。 |

| 微量添加物 | <1% | 耐食性や熱安定性など、特定の特性を強化する。 |

ストレートクーラントホール超硬ロッドの用途

| 産業 | 申し込み |

|---|---|

| 航空宇宙 | タービン部品や機体部品の精密穴あけ・機械加工に使用。 |

| 自動車 | エンジン部品、トランスミッション部品などの加工に不可欠。 |

| 医療機器 | 高精度と衛生が要求される手術器具やインプラントの製造に利用される。 |

| 石油・ガス | 高圧環境に直面する掘削装置や部品の製造に使用される。 |

| 金型 | 優れた精度で金型や切削工具を製作するために不可欠。 |

| エレクトロニクス | コネクターや半導体部品など、小型で精密な部品の製造に役立つ。 |

| 建設 | 強化鋼や硬質合金などの建設材料の加工におけるヘビーデューティー・アプリケーションをサポート。 |

超硬ストレートクーラントホールの製造工程フロー

まっすぐなクーラントホールの超硬ロッドを作るには、細心の注意が必要です。その方法を紹介しよう:

- パウダーの準備:炭化タングステン粉末にコバルトなどのバインダーを配合。

- ミキシング:混合物は、一貫した特性を保証するために均一に結合される。

- コンパクト化:粉末は、冷却孔用の溝がある棒状にプレスされる。

- 焼結前:最終焼結の前に、ロッドを低温で加熱して構造を強化する。

- 焼結:高温での最終焼結により、緻密で頑丈な製品ができる。

- 冷却:徐冷により安定性を確保し、内部応力を最小限に抑える。

- 仕上げ:精密基準を満たすための研削、研磨、品質チェックを含む。

材料特性 ストレートクーラントホール超硬ロッド

| プロパティ | 値の範囲 | 意義 |

|---|---|---|

| 硬度 | 89-94 HRA | 優れた耐摩耗性と長寿命を確保。 |

| 密度 | 14.1-15.1 g/cm³ | ヘビーデューティ用途に必要な堅牢性を提供。 |

| 引張強度 | 2500-4000 MPa | これにより、ロッドは変形することなく大きな応力に耐えることができる。 |

| 熱伝導率 | 60-100 W/m-K | 高速加工時の効率的な放熱を促進。 |

| 曲げ強度 | 400-650 MPa | ロッドが使用中の曲げ力に耐えられることを保証する。 |

仕様、サイズ、規格

| パラメータ | 利用可能なオプション |

|---|---|

| 直径 | 0.5 mm~25 mm |

| 長さ | 50 mm~330 mm |

| クーラントホールサイズ | 0.2 mm~10 mm |

| 規格 | ISO9001、DIN、ANSI |

| シェイプス | 円筒形、六角形、またはカスタマイズされたプロファイル。 |

正しいストレートクーラントホール超硬棒の選択

| ファクター | 考察 |

|---|---|

| 素材タイプ | 用途に必要な硬度と靭性に応じてお選びください。 |

| クーラントホール設計 | 冷却の必要性に応じて、シングルホールかダブルホールを選択する。 |

| 加工速度 | 高速回転では、効率的な熱放散のためのヘリカルクーラントホールが役立ちます。 |

| ツールサイズ | ロッドの直径と長さを工具の仕様に合わせる。 |

| コスト | 品質に妥協することなく、費用対効果の高いオプションを選ぶ。 |

利点と限界

| メリット | 制限事項 |

|---|---|

| 優れた耐摩耗性と長寿命。 | 標準的なロッドに比べてイニシャルコストが高い。 |

| 冷却の強化により、工具の摩耗を低減。 | 正確なハンドリングとセットアップが必要。 |

| 業種を問わない多用途なアプリケーション。 | カスタマイズの柔軟性に制限がある。 |

| ISO規格はグローバルな互換性を保証する。 | 在庫状況はサプライヤーや仕様によって異なる場合があります。 |

よくあるご質問

| 質問 | 回答 |

|---|---|

| 超硬ストレートクーラントホールの特徴は? | クーラントホールは、加工中の潤滑と放熱を改善する。 |

| 正しいロッドの選び方は? | 用途に応じて、材質、直径、長さ、クーラントホールの設計を検討してください。 |

| カスタマイズは可能か? | はい、多くのメーカーが特注サイズや仕様に対応しています。 |

| このロッドはどのような産業で使われているのか? | 航空宇宙、自動車、医療、建設など。 |

| このロッドの一般的な寿命はどのくらいですか? | 使い方にもよるが、適切な手入れをすれば、従来のロッドよりかなり長持ちする。 |