はじめに精密工学とねじ接続の出会い

複雑な機械加工の世界では、ねじ山の加工ほど精度と制御が要求される作業はありません。このようならせん状の溝は、数え切れないほどの用途において、確実な締結と正確な動作に不可欠であり、次のような特殊な切削工具に依存している。 スレッディング インサート ターニング用.この包括的なガイドは、ねじ切りインサートの魅力的な領域を掘り下げ、その複雑さを解明し、多様な用途を探求し、卓越したねじ切りを達成するための知識を機械加工者に与える。

ねじ切りインサートを解明:精密ねじ切りの礎石

スレッディング・インサートとは?

旋削用ねじ切りチップ は、旋盤やターニングセンターで外ねじや内ねじを加工するために特別に設計された刃先交換式切削工具です。一般的な旋削加工に使用されるものと異なり、ねじ切りインサートは、希望するねじの形状、ピッチ、直径に対応するように精密に研削された切れ刃を備えています。この特殊な形状により、ねじの仕様や加工される材料に応じて、1パスまたは複数パスで効率的かつ正確にねじを作成することができます。

スレッド作成のメカニズム

ねじ切りチップの魔法は、らせん状の経路に沿って材料を正確に除去し、希望のねじ山形状を徐々に形成する能力にあります。インサートがスピンドルと共に回転すると、その刃先が被削材にかみ合い、制御された刻みで被削材を剪断除去します。主軸の回転速度と同期した工具の送り速度がねじ山のピッチを決定し、切り込み深さがねじ山の深さ、ひいては主要直径を決定する。

製造工程:原材料から精密工具まで:

ねじ切りインサートが原材料から精密切削工具になるまでの道のりは、高度な製造技術の証である:

- 粉末冶金: ほとんどのねじ切りインサートは、炭化タングステンに代表される微細な超硬合金粉末と、特定の特性を向上させるバインダーやその他の添加剤のブレンドから始まります。

- プレスと成形: その後、混合粉末は金型内で大きな圧力をかけられ、刃先やチップブレーカーの形状を含むチップの基本的な形状が形成される。

- 焼結: プレス加工されたチップは、制御された雰囲気の中で高温焼結工程を受けます。この重要な工程で炭化物粒子が融合し、チップの硬度、強度、耐摩耗性が向上します。

- コーティング(オプション): さらに性能を向上させるために、多くのねじ切りインサートには、窒化チタン(TiN)や炭窒化チタン(TiCN)のような、薄く非常に硬いコーティングが施されています。これらのコーティングは、耐摩耗性を向上させ、摩擦を減らし、工具寿命を延ばします。

- 研磨と仕上げ: 最終段階では、特定のねじ形状と用途に必要な正確な寸法と刃先形状を達成するために、精密研削が行われる。インサートはまた、特定の表面仕上げを達成するためにホーニングや研磨を受けることもあります。

ねじ切りインサートの分類:選択肢の世界:

ねじ切りインサートは万能ではありません。それぞれ特定のねじ形状、材料、加工要件に合わせて調整されています:

- フルプロファイル・インサート: ねじ切り界の主力製品であるこのねじ切り工具は、刃先に完全なねじ山形状を備えているため、1回のパスでねじ山を形成することができます。スピードと効率が最優先される大量生産環境において、優れた性能を発揮する。

- パーシャル・プロファイル・インサート: より高い柔軟性を提供するこれらのインサートは、ねじ山形状の一部のみを特徴としており、完全なねじ山を生成するために複数のパスを必要とします。この特徴により、ねじの深さを微調整することができ、特に強靭な材料を使用する場合や、特定のねじ特性を目指す場合に有利です。

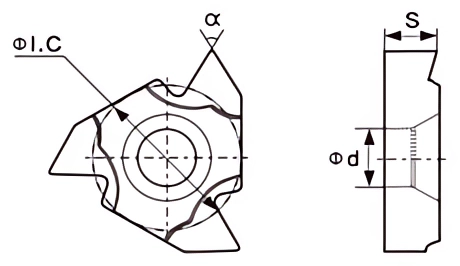

- マルチ・トゥース・インサート: その名が示すように、これらのチップは複数の歯または切れ刃を誇り、切削抵抗の低減による高速ねじ切り加工を可能にします。大径のねじ切りや、振動の多い被削材に最適です。

ねじ切りインサート形状:最適性能のための微調整:

ねじ切りチップの形状の微妙な違いを理解することは、優れたねじ切り品質を達成し、工具寿命を最大限に延ばすために非常に重要です:

- レーキの角度: 他の旋削チップと同様に、すくい角は切削抵抗、切り屑の厚さ、仕上げ面に大きく影響します。正のすくい角は、より滑らかな切削作用とより薄い切り屑を促進し、負のすくい角は、刃先強度を高め、特に難削材での切り屑処理を改善します。

- リードアングル: リード角は、切削するねじ山の螺旋角度によって決定され、切れ刃が被削材にどれだけ徐々に食い込むかを決定する。リード角を大きくすると、より滑らかで緩やかな切削となり、リード角を小さくすると、切削抵抗が増加し、仕上げ面に影響を与える可能性があります。

- クリアランスアングル: この重要な角度は、チップと加工されたばかりのねじ山形状との摩擦を防ぎ、摩擦、発熱、工具摩耗を低減します。適切な逃げ角は、ねじの形状精度を維持し、工具寿命を延ばすために不可欠です。

- チップブレーカー ねじ切りチップは、切屑の形成を制御し、切屑の流れを切削領域から遠ざける重要な役割を果たす、特別に設計されたチップブレーカーを備えていることがよくあります。効果的な切りくずの制御は、切りくずの蓄積を防ぐために最も重要です。この切りくずは、仕上げ面を傷つけ、ねじの品質を損ない、工具の破損につながることさえあります。

ISO分類システムの解読インサートを材料に適合させる:

超硬材種の世界をナビゲートすることは、秘密 の暗号を解読するように感じるかもしれませ んが、心配はいりません!国際標準化機構(ISO)システムは、その特性と理想的な用途に基づいて超硬材種を分類するための標準化された枠組みを提供します:

| アプリケーショングループ | 説明 |

|---|---|

| P | 鋼鉄、鋳鋼品、切屑が長く連続する材料の加工用に設計。 |

| M | ステンレス鋼、高温合金、その他の機械加工が難しく、耐熱性と耐摩耗性の向上が要求される材料の課題に取り組むために設計されています。 |

| K | 鋳鉄、非鉄金属、非金属材料を扱うのに最適で、硬度と靭性のバランスが取れているため、多様な材料に対応できる。 |

アプリケーション・グループ文字に続く数字は、通常、インサートの横方向破断強度(TRS)と硬度を示し、総合的な強度と耐摩耗性を示しています。

ねじ切りインサートの活躍:アプリケーションの世界:

ねじ切りインサートは、さまざまな産業で無数のねじ接続を支える縁の下の力持ちです:

- 自動車: エンジンブロックやシリンダーヘッドからトランスミッション部品やサスペンションシステムに至るまで、ねじ切りインサートは自動車の信頼性と性能を保証し、安全性とドライビングプレジャーに貢献しています。

- 航空宇宙 航空宇宙産業は、最高の精度と信頼性を要求しており、航空機構造、エンジン部品、重要な飛行制御システムにおいて、軽量でありながら驚異的な強度を持つねじ接続部を作成するために、ねじ切りインサートを頼りにしています。

- 医療機器 生命が危険にさらされているとき、精度が最も重要です。ねじ切りインサートは、医療用インプラント、手術器具、診断機器の製造において重要な役割を果たしており、そこでは精密なねじ山が生体適合性、機能性、患者の安全性を保証しています。

- エネルギーだ: エネルギーの抽出と利用には、極端な温度、高圧、腐食性の環境がしばしば伴います。ねじ切りインサートは、石油・ガス探査、発電、再生可能エネルギーシステム用の堅牢なねじ接続を実現するのに役立っています。

- エレクトロニクス: エレクトロニクスの小型化が進む中、ねじ切りインサートは、コネクター、ハウジング、取り付け金具などの部品に驚くほど小さく精密なねじ山を作ることを可能にし、技術世界の小型化に貢献しています。

長所と短所を比較する:ねじ切りインサートの利点と限界:

| メリット | 制限事項 |

|---|---|

| 卓越したねじ品質:ねじ切りインサートは、高精度、一貫したピッチ、優れた表面仕上げのねじ山を生産することに優れており、様々な産業界の厳しい要求を満たしています。 | コスト:長期的には費用対効果が高いが、ねじ切りインサートは、他のねじ切り方法と比較して、特に少量生産の用途では初期投資が高くなる可能性がある。 |

| 汎用性:様々なねじ形状、ピッチ、サイズ、材質のねじ切りインサートが用意されており、ねじ切り作業において比類のない多様性を提供します。 | セットアップと工具ねじ切りインサートで最適な結果を得るには、正確な機械のセットアップ、適切な工具保持、切削パラメータの慎重な選択が必要です。 |

| 効率性と生産性:ねじ切りチップの交換可能な設計により、新しい切れ刃に素早く簡単に交換できるため、ダウンタイムを最小限に抑え、生産性を向上させることができます。 | 切りくず処理:特に、深穴加工や切り屑が堆積しやすい被削材を使用する場合、切り屑の制御は困難です。効果的なチップブレーカーを備えたチップを選択し、切削パラメータを最適化することが重要です。 |

| 工具寿命の延長:耐久性の高い超硬基材と高度なコーティングの組み合わせは、工具寿命の延長に貢献し、特に大量生産環境では、長期にわたって工具コストを削減します。 | 破損の可能性耐久性がある一方で、過度の切削力がかかったり、不適切なクランプが行われたり、インサートがツールホルダー内で適切に固定されていないと、ねじ切りインサートが破損する可能性がある。 |

よくある質問スレッド挿入クエリへの対応:

1.特定の用途に適したねじ切りインサートを選ぶには?

最適なねじ切りインサートを選択するには、以下のようないくつかの要素を考慮する必要がある:

- スレッドの形式 必要なねじ規格(UN、UNF、Metricなど)と特定のねじ形状を決定する。

- ピッチと直径: 希望のねじピッチと長径を指定する。

- 素材: 材質が異なれば、特定の超硬等級とコーティングを施したチップが必要になるため、ねじ切りする材質を特定してください。

- ねじの品質と公差: 必要なねじの品質と公差レベルを定義する。

- 工作機械の能力: 主軸回転数、送り速度、剛性など、旋盤やターニングセンターの能力を考慮してください。

- 切断パラメータ: 適切な切削速度、送り速度、切り込み深さについては、選択したインサートと材料に基づき、メーカーの推奨事項を参照してください。

2.ねじ切りインサートを使用するためのねじ切り工具ホルダーを選択する際の主な考慮事項は何ですか?

適切なツールホルダを選択することは、適切なチップサポート、剛性、精度を確保するために非常に重要です:

- 工作機械のインターフェイス: 旋盤やターニングセンターの刃物台やタレットとの互換性を確認してください。

- インサートのサイズとスタイル: 選択したねじ切りインサートのサイズとスタイルに確実に対応するホルダーを選択する。

- オーバーハング: 工具のオーバーハングを最小限に抑え、振動を低減し、ねじ切り精度を向上。

- クーラントの供給: 特に要求の厳しい用途では、切屑排出と工具寿命を向上させるために、内部クーラント供給チャンネルを備えたホルダーをご検討ください。

3.ねじ切りインサートを使用する際、切り屑の堆積を防ぎ、効率的に切り屑を排出するにはどうすればよいですか?

最適なねじ切り結果を得るためには、効果的な切りくず処理が不可欠です:

- チップブレーカーの選択 材料とねじ切り作業用に特別に設計されたチップブレーカー付きのチップを選択する。

- 切断パラメータ: 切削速度、送り速度、切り込み深さを最適化し、良好な切り屑の形成と排出を促進する。

- クーラントの供給: 切りくずを流し、切削ゾーンを冷やすために、適切なクーラント流量と圧力を確保してください。

- 高圧クーラント: 特に深穴のねじ切り加工や、切り屑が溶着しやすい材料を加工する場合は、切り屑の排出性を高めるために高圧クーラントシステムの使用を検討してください。

4.コーティングされたねじ切りインサートを使用する利点は何ですか?

コーティングは、ねじ切り作業において大幅な性能向上をもたらす:

- 耐摩耗性の向上: コーティングは保護バリアとして機能し、チップとワーク間の摩擦と摩耗を低減し、工具寿命を延ばす。

- 強化された硬度: コーティングは表面硬度を高め、切削速度の高速化と耐摩耗性の向上を可能にする。

- 潤滑性の向上: 一部のコーティングは潤滑特性を示し、摩擦と発熱をさらに低減し、スムーズな切削動作と表面仕上げの向上につながる。

- 耐酸化性: コーティングは、高温でのチップの耐酸化性を向上させることができ、特に高速加工や難削材加工に有効です。

5.新しい刃先を露出させるために、ねじ切りインサートを適切に割り出すにはどうすればよいですか?

ねじ切りインサートの割り出しは簡単な作業だが、細部に注意を払う必要がある:

- メーカーの指示に従うこと: 具体的な割り出し手順については、インサートの設計によっ て若干異なる場合があるため、必ずインサート・メーカーの説明書を参 照してください。

- クランプを緩める: 付属のレンチを使用し、過度な力を加えないように注意しながら、インサート・クランプを緩める。

- インサートを回転させる: インサートを慎重に回転させ、ツールホルダ ー内で適切に位置合わせされていることを確認しながら、次 の使用可能な刃先まで回転させる。

- しっかりクランプ: インサートがしっかりと固定され、加工中にインサートが動かないことを確認しながら、インサート・クランプをしっかりと締めます。

- アライメントを確認する: ねじ切り作業を再開する前に、チップのアライメントを再チェックし、ねじの品質や工具の破損に関する潜在的な問題を防いでください。

高品質の超硬インサートを適正価格で購入したいですか?クリック これ.