Introduction: When Only Brute Strength Will Do

In the demanding world of heavy-duty machining, where massive workpieces and unforgiving materials test the limits of tooling technology, only the toughest tools survive. Enter Type D carbure pointes brasées, the workhorses of the machining world, engineered to conquer the most challenging cutting conditions with unmatched power and resilience.

This article delves into the realm of Type D carbide brazed tips, exploring their unique characteristics, advantages, and the reasons why they’re the go-to choice when maximum metal removal and unwavering reliability are non-negotiable.

The Heavyweights of Machining: Tackling the Toughest Applications

Where Other Tools Falter, Type D Tips Prevail

Heavy-duty machining operations, characterized by:

- Taux d'enlèvement de matière élevé : Removing large volumes of material quickly and efficiently.

- Matériaux difficiles à usiner : Working with tough, abrasive, or high-temperature alloys that can quickly wear down conventional tooling.

- Extreme Cutting Forces: Generating substantial cutting forces that demand robust tooling and machine setups.

These demanding conditions require carbide brazed tips with exceptional:

- Strength and Toughness: To withstand the immense forces and stresses encountered during heavy cuts.

- Résistance à l'usure : To maintain cutting edge integrity and tool life when machining abrasive materials.

- Stabilité thermique : To resist deformation and maintain cutting edge sharpness at elevated temperatures generated during high-speed machining.

Type D Carbide Brazed Tips: Built for Maximum Metal Removal

A Symphony of Strength and Durability

Type D carbide brazed tips are purpose-built for heavy-duty machining, distinguished by their:

- Neutral or Slightly Positive Rake Angles: This rake angle strikes a balance between cutting edge strength and sharpness, providing:

- Robust Cutting Edges: To withstand the high impact loads and interrupted cuts common in heavy-duty machining.

- Efficient Chip Flow: Facilitating the removal of large chips generated during high-volume material removal.

- Large Nose Radii: The larger nose radius on Type D tips provides:

- Increased Cutting Edge Strength: Distributing cutting forces over a wider area, reducing the risk of chipping or breakage.

- Improved Surface Finish at Higher Feed Rates: While not primarily known for finishing, the larger nose radius allows for acceptable surface finishes even at the higher feed rates typical in heavy-duty machining.

- Grades de carbure résistants : Type D tips often utilize extra-tough carbide grades with high cobalt (Co) content or additions of other elements like tantalum (Ta) or niobium (Nb). These grades offer:

- Exceptional Strength and Toughness: To handle the extreme forces encountered in heavy-duty machining.

- Haute résistance à l'usure : Prolonging tool life when machining abrasive materials.

- Stabilité thermique : Maintaining cutting edge integrity at elevated temperatures.

Advantages of Type D Carbide Brazed Tips in Heavy-Duty Machining

Powering Through the Most Demanding Cuts

The robust design and material properties of Type D carbide brazed tips translate into several key advantages:

- Taux d'enlèvement de matière élevé : Their strength and toughness allow for aggressive cutting parameters, maximizing productivity and reducing machining time.

- Extended Tool Life in Challenging Materials: Their wear resistance ensures prolonged tool life, even when machining abrasive or high-temperature alloys.

- Reliability and Predictability: Their robust construction minimizes the risk of unexpected tool failure, ensuring consistent performance and predictable outcomes.

- Versatility in Heavy-Duty Applications: Type D tips are suitable for a wide range of heavy-duty machining operations, including milling, turning, boring, and grooving.

Applications of Type D Carbide Brazed Tips

Where Power and Durability Reign Supreme

Type D carbide brazed tips excel in heavy-duty machining applications where other tools fall short, including:

- Opérations d'ébauche : Rapidly removing large amounts of material in milling and turning.

- Machining High-Temperature Alloys: Working with materials like inconel, titanium, and stainless steels that generate high cutting temperatures.

- Coupe de matériaux abrasifs : Machining cast iron, hardened steels, and other materials that can quickly wear down conventional tooling.

- Heavy Interrupted Cuts: Withstanding the shock loads and fluctuating forces encountered in applications like milling, where the tool repeatedly enters and exits the workpiece.

Choosing the Right Type D Carbide Brazed Tip: Factors to Consider

Optimizing Tooling Selection for Extreme Conditions

Selecting the optimal Type D carbide brazed tip involves carefully evaluating:

- Matériau de la pièce : La dureté, l'abrasivité et les propriétés thermiques du matériau sont des facteurs cruciaux pour déterminer la nuance de carbure et le revêtement appropriés.

- Opération d'usinage : The specific heavy-duty operation, such as rough milling, turning of high-temperature alloys, or boring of large diameters, influences the choice of tip geometry and size.

- Paramètres de coupe : Desired cutting speeds, feed rates, and depths of cut play a significant role in tip selection, as they directly impact cutting forces and temperatures.

- Capacité des machines-outils : La rigidité et la puissance de la machine-outil peuvent limiter le choix de la taille de la pointe et des paramètres de coupe.

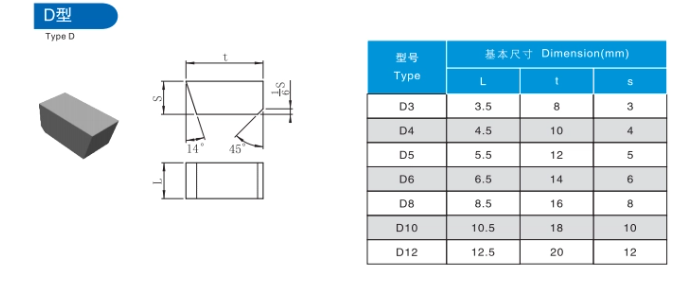

Type D Carbide Brazed Tip Selection: A Simplified Guide

To assist in the selection process, here’s a table summarizing typical applications and considerations for different Type D tip geometries:

| Type D Tip Geometry | Applications typiques | Principales considérations |

|---|---|---|

| High-Positive Insert | High-feed milling, rough turning | Provides a good balance of strength and chip flow |

| Double-Negative Insert | Heavy-duty turning, interrupted cuts | Offers maximum strength and resistance to chipping |

| Button Insert | Heavy-duty boring, deep grooving | Provides maximum support and rigidity for large depths of cut |

Frequently Asked Questions about Type D Carbide Brazed Tips

Q1: Can Type D carbide brazed tips be used for finishing operations?

A1 : While not ideal for achieving fine surface finishes, Type D tips can be used for finishing cuts in some heavy-duty applications where surface finish requirements are less stringent.

Q2: What are the signs of wear on a Type D carbide brazed tip?

A2 : Common wear signs include flank wear on the cutting edge, cratering on the rake face, and plastic deformation of the cutting edge due to high temperatures.

Q3: How can I maximize the tool life of my Type D carbide brazed tips in heavy-duty machining?

A3 : Key factors include selecting the appropriate tip geometry and grade for the application, optimizing cutting parameters (balancing material removal rate with tool life), using high-pressure coolant systems, and ensuring a rigid machine setup.

Q4: What is the difference between a high-positive insert and a double-negative insert Type D tip?

A4 : High-positive inserts are designed for efficient chip flow and high-feed milling applications, while double-negative inserts offer maximum strength and resistance to chipping in heavy-duty turning and interrupted cutting operations.

Q5: When would I choose a button insert Type D tip?

A5 : Button inserts are the go-to choice for heavy-duty boring and deep grooving applications where maximum support and rigidity are required to prevent tool deflection and ensure accurate hole diameters or groove dimensions.