Introduction : La rencontre de l'ingénierie de précision et des raccords filetés

Dans le monde complexe de l'usinage, peu de tâches exigent autant de précision et de contrôle que la création de filets. Ces rainures hélicoïdales, essentielles pour des fixations sûres et des mouvements précis dans d'innombrables applications, s'appuient sur des outils de coupe spécialisés, les filets. filetage inserts pour tourner. Ce guide complet se penche sur le domaine fascinant des plaquettes de filetage, en démêlant leurs complexités, en explorant leurs diverses applications et en donnant aux machinistes les connaissances nécessaires pour atteindre l'excellence en matière de filetage.

Les plaquettes de filetage démystifiées : La pierre angulaire du filetage de précision

Qu'est-ce qu'un insert fileté ?

Plaquettes de filetage pour le tournage sont des outils de coupe indexables spécialement conçus pour usiner des filets extérieurs et intérieurs sur des tours ou des centres de tournage. Contrairement à leurs homologues utilisés pour les opérations générales de tournage, les plaquettes de filetage présentent des arêtes de coupe rectifiées avec précision qui correspondent à la forme, au pas et au diamètre du filet souhaité. Cette géométrie spécialisée permet la création efficace et précise de filets en une ou plusieurs passes, en fonction des spécifications du filet et du matériau usiné.

La mécanique de la création de fils :

La magie des plaquettes de filetage réside dans leur capacité à enlever avec précision de la matière le long d'une trajectoire hélicoïdale, formant progressivement le profil de filetage souhaité. Lorsque la plaquette tourne avec la broche, son arête de coupe s'engage dans la pièce à usiner, cisaillant la matière par incréments contrôlés. La vitesse d'avance de l'outil, synchronisée avec la vitesse de la broche, détermine le pas du filet, tandis que la profondeur de coupe détermine la profondeur du filet et, en fin de compte, son diamètre principal.

Processus de fabrication : De la matière première à l'outil de précision :

Le parcours d'un insert de filetage, de la matière première à l'outil de coupe de précision, témoigne des techniques de fabrication avancées :

- Métallurgie des poudres : La plupart des plaquettes de filetage sont d'abord un mélange de poudres fines de carbure, généralement de carbure de tungstène, avec des liants et d'autres additifs qui améliorent les propriétés spécifiques.

- Pressage et mise en forme : Le mélange de poudres est ensuite soumis à une énorme pression dans un moule, formant la forme de base de la plaquette, y compris ses arêtes de coupe et la géométrie du brise-copeaux.

- Frittage : Les plaquettes pressées subissent un processus de frittage à haute température dans une atmosphère contrôlée. Cette étape critique fusionne les particules de carbure, augmentant ainsi la dureté, la solidité et la résistance à l'usure de la plaquette.

- Revêtement (en option) : Pour améliorer encore les performances, de nombreuses plaquettes de filetage sont recouvertes d'un revêtement mince et incroyablement dur, tel que le nitrure de titane (TiN) ou le carbonitrure de titane (TiCN). Ces revêtements améliorent la résistance à l'usure, réduisent la friction et augmentent la durée de vie de l'outil.

- Meulage et finition : L'étape finale consiste en un meulage de précision pour obtenir les dimensions exactes et la géométrie de l'arête de coupe requises pour la forme et l'application spécifiques du filetage. Les plaquettes peuvent également subir un honage ou un polissage pour obtenir une finition de surface spécifique.

Catégorisation des filets rapportés : Un monde d'options :

Les filets rapportés ne sont pas une solution unique. Elles existent dans une gamme impressionnante de types, chacun adapté à des formes de filetage, des matériaux et des exigences d'usinage spécifiques :

- Inserts à profil intégral : Ces bêtes de somme du monde du filetage présentent un profil de filetage complet sur leur arête de coupe, ce qui permet de créer des filets en une seule passe. Ils excellent dans les environnements de production à haut volume où la vitesse et l'efficacité sont primordiales.

- Inserts à profil partiel : Offrant une plus grande flexibilité, ces inserts ne présentent qu'une partie du profil du filet, nécessitant plusieurs passes pour générer un filet complet. Cette caractéristique permet d'affiner la profondeur du filetage et est particulièrement avantageuse lorsque l'on travaille avec des matériaux résistants ou que l'on recherche des caractéristiques de filetage spécifiques.

- Inserts multi-dents : Comme leur nom l'indique, ces plaquettes comportent plusieurs dents ou arêtes de coupe, ce qui permet des opérations de filetage plus rapides avec des forces de coupe réduites. Elles constituent le choix idéal pour le filetage de diamètres plus importants ou pour les matériaux sujets aux vibrations.

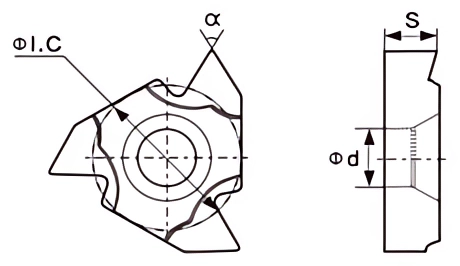

Géométries des plaquettes de filetage : Ajustement fin pour une performance optimale :

Il est essentiel de comprendre les nuances des géométries des plaquettes de filetage pour obtenir une qualité de filetage supérieure et optimiser la durée de vie de l'outil :

- Angle d'inclinaison : Comme pour les autres plaquettes de tournage, l'angle de coupe influence considérablement les efforts de coupe, l'épaisseur des copeaux et l'état de surface. Les angles de coupe positifs favorisent une action de coupe plus douce et des copeaux plus fins, tandis que les angles de coupe négatifs renforcent la résistance des arêtes et améliorent le contrôle des copeaux, en particulier dans les matériaux difficiles.

- Angle d'attaque : Dicté par l'angle d'hélice du fil à couper, l'angle d'attaque détermine la progressivité de l'engagement de l'arête de coupe dans la pièce à usiner. Un angle d'attaque plus important permet d'obtenir une coupe plus douce et plus progressive, tandis qu'un angle d'attaque plus faible augmente les forces de coupe, ce qui peut avoir un impact sur la finition de la surface.

- Angle de dégagement : Cet angle critique empêche le frottement entre la plaquette et les flancs du filet fraîchement usinés, réduisant ainsi la friction, la production de chaleur et l'usure de l'outil. Des angles de dépouille corrects sont essentiels pour maintenir la précision de la forme du filet et prolonger la durée de vie de l'outil.

- Casse-pipe : Les plaquettes de filetage sont souvent équipées de brise-copeaux spécialement conçus qui jouent un rôle crucial dans le contrôle de la formation des copeaux et dans l'éloignement du flux de copeaux de la zone de coupe. Un contrôle efficace des copeaux est primordial pour éviter l'accumulation de copeaux, qui peut nuire à la finition de la surface, compromettre la qualité du filetage et même entraîner la rupture de l'outil.

Décoder le système de classification ISO : Correspondance entre les notices et les matériaux :

Naviguer dans le monde des nuances de carbure peut ressembler à déchiffrer un code secret, mais n'ayez crainte ! Le système de l'Organisation internationale de normalisation (ISO) fournit un cadre normalisé pour la classification des nuances de carbure en fonction de leurs propriétés et de leurs applications idéales :

| Groupe d'application | Description |

|---|---|

| P | Conçue pour l'usinage de l'acier, des pièces moulées en acier et des matériaux connus pour produire des copeaux longs et continus. |

| M | Conçus pour relever les défis des aciers inoxydables, des alliages à haute température et d'autres matériaux qui ont tendance à être plus difficiles à usiner et qui nécessitent une résistance accrue à la chaleur et à l'usure. |

| K | Le choix idéal pour maîtriser la fonte, les métaux non ferreux et les matériaux non métalliques, offrant un équilibre de dureté et de résistance pour traiter ces divers matériaux. |

Le nombre qui suit la lettre du groupe d'application indique généralement la résistance à la rupture transversale (TRS) et la dureté de la plaquette, ce qui donne une idée de sa résistance globale et de sa résistance à l'usure.

Les filets rapportés en action : Un monde d'applications :

Les inserts filetés sont les héros méconnus d'innombrables raccords filetés dans une multitude d'industries :

- Automobile : Des blocs moteurs et des culasses aux composants de transmission et aux systèmes de suspension, les inserts de filetage garantissent la fiabilité et les performances des véhicules, contribuant ainsi à la sécurité et au plaisir de conduire.

- Aérospatiale : L'industrie aérospatiale exige la plus grande précision et la plus grande fiabilité. Elle s'appuie sur les inserts de filetage pour créer des connexions filetées légères mais incroyablement solides dans les structures des avions, les composants des moteurs et les systèmes de contrôle de vol critiques.

- Dispositifs médicaux : Lorsque des vies sont en jeu, la précision est primordiale. Les inserts filetés jouent un rôle essentiel dans la fabrication d'implants médicaux, d'instruments chirurgicaux et d'équipements de diagnostic, où la précision des filets garantit la biocompatibilité, la fonctionnalité et la sécurité des patients.

- L'énergie : L'extraction et l'exploitation de l'énergie impliquent souvent des températures extrêmes, des pressions élevées et des environnements corrosifs. Les inserts filetés jouent un rôle essentiel dans la création de raccords filetés robustes pour l'exploration pétrolière et gazière, la production d'électricité et les systèmes d'énergie renouvelable.

- Électronique : Alors que l'électronique continue de se rétrécir, les inserts de filetage permettent de créer des filetages incroyablement petits et précis dans des composants tels que les connecteurs, les boîtiers et le matériel de montage, contribuant ainsi à la miniaturisation de notre monde technologique.

Peser le pour et le contre : avantages et limites des inserts de filetage :

| Avantages | Limites |

|---|---|

| Qualité exceptionnelle des filets : Les plaquettes de filetage excellent dans la production de filets d'une grande précision, d'un pas constant et d'une finition de surface supérieure, répondant ainsi aux exigences rigoureuses de diverses industries. | Coût : Bien que rentables à long terme, les inserts de filetage peuvent représenter un investissement initial plus élevé que d'autres méthodes de filetage, en particulier pour les applications à faible volume. |

| Polyvalence : Disponibles dans une vaste gamme de formes de filets, de pas, de tailles et de matériaux, les inserts de filetage offrent une polyvalence inégalée dans les opérations de filetage. | Réglage et outillage : Pour obtenir des résultats optimaux avec les plaquettes de filetage, il faut un réglage précis de la machine, un bon maintien de l'outil et une sélection minutieuse des paramètres de coupe. |

| Efficacité et productivité : La conception indexable des plaquettes de filetage permet une indexation rapide et facile sur une nouvelle arête de coupe, minimisant ainsi les temps d'arrêt et augmentant la productivité. | Contrôle des copeaux : Le contrôle des copeaux peut s'avérer difficile, en particulier lors du filetage de trous profonds ou de l'utilisation de matériaux susceptibles d'accumuler des copeaux. Il est essentiel de sélectionner des plaquettes dotées de brise-copeaux efficaces et d'optimiser les paramètres de coupe. |

| Durée de vie prolongée des outils : Les substrats durables en carbure, combinés à des revêtements avancés, contribuent à prolonger la durée de vie des outils, réduisant ainsi les coûts d'outillage au fil du temps, en particulier dans les environnements de production en grande quantité. | Risque de rupture : Bien que durables, les plaquettes de filetage peuvent se casser si elles sont soumises à des forces de coupe excessives, à un mauvais serrage ou si la plaquette n'est pas correctement fixée dans le porte-outil. |

Foire aux questions : Répondre à vos questions sur l'insertion de fils :

1. Comment choisir l'insert de filetage adapté à mon application spécifique ?

Le choix de l'insert de filetage optimal implique la prise en compte de plusieurs facteurs, notamment

- Forme du fil : Déterminer la norme de filetage requise (par exemple, UN, UNF, métrique) et la forme spécifique du filetage.

- Pas et diamètre : Spécifiez le pas de vis et le diamètre principal souhaités.

- Matériau : Identifier le matériau à fileter, car les différents matériaux nécessitent des plaquettes avec des nuances de carbure et des revêtements spécifiques.

- Qualité et tolérance des filetages : Définir la qualité du filetage et les niveaux de tolérance requis, car cela influencera le choix de la géométrie et de la nuance de la plaquette.

- Capacités des machines-outils : Prenez en compte les capacités de votre tour ou centre de tournage, notamment la vitesse de la broche, la vitesse d'avance et la rigidité.

- Paramètres de coupe : Consulter les recommandations du fabricant pour connaître les vitesses de coupe, les vitesses d'avance et les profondeurs de coupe appropriées en fonction de la plaquette et du matériau choisis.

2. Quelles sont les principales considérations à prendre en compte lors du choix d'un porte-outil de filetage à utiliser avec des plaquettes de filetage ?

Le choix du bon porte-outil est crucial pour assurer le support, la rigidité et la précision de la plaquette :

- Interface machine-outil : Assurez-vous de la compatibilité avec le porte-outil ou la tourelle de votre tour ou centre de tournage.

- Taille et style de l'insert : Sélectionnez un support qui s'adapte parfaitement à la taille et au style de l'insert fileté choisi.

- Surplomb : Minimiser le dépassement de l'outil pour réduire les vibrations et améliorer la précision du filetage.

- Alimentation en liquide de refroidissement : Envisagez des porte-outils avec des canaux d'arrosage internes pour améliorer l'évacuation des copeaux et la durée de vie de l'outil, en particulier dans les applications exigeantes.

3. Comment éviter l'accumulation de copeaux et assurer une évacuation efficace des copeaux lors de l'utilisation d'inserts de filetage ?

Un contrôle efficace des copeaux est essentiel pour obtenir des résultats de filetage optimaux :

- Sélection Chipbreaker : Choisissez des plaquettes avec des brise-copeaux spécialement conçus pour le matériau et l'opération de filetage.

- Paramètres de coupe : Optimiser les vitesses de coupe, les vitesses d'avance et les profondeurs de coupe pour favoriser la formation et l'évacuation des copeaux.

- Alimentation en liquide de refroidissement : Veillez à ce que le débit et la pression du liquide de refroidissement soient suffisants pour évacuer les copeaux et maintenir la zone de coupe froide.

- Liquide de refroidissement à haute pression : Envisagez d'utiliser des systèmes d'arrosage à haute pression pour améliorer l'enlèvement des copeaux, en particulier lors du filetage de trous profonds ou de l'usinage de matériaux susceptibles d'être soudés par copeaux.

4. Quels sont les avantages de l'utilisation d'inserts filetés revêtus ?

Les revêtements améliorent considérablement les performances des opérations de filetage :

- Résistance accrue à l'usure : Les revêtements agissent comme une barrière protectrice, réduisant le frottement et l'usure entre la plaquette et la pièce, ce qui prolonge la durée de vie de l'outil.

- Dureté améliorée : Les revêtements augmentent la dureté de la surface, ce qui permet des vitesses de coupe plus élevées et une meilleure résistance à l'usure abrasive.

- Lubrification améliorée : Certains revêtements présentent des propriétés lubrifiantes, réduisant encore le frottement et la production de chaleur, ce qui permet une coupe plus douce et un meilleur état de surface.

- Résistance à l'oxydation : Les revêtements peuvent améliorer la résistance de la plaquette à l'oxydation à des températures élevées, ce qui est particulièrement utile lors de l'usinage à des vitesses plus élevées ou avec des matériaux difficiles à couper.

5. Comment indexer correctement une plaquette de filetage pour exposer une nouvelle arête de coupe ?

L'indexation d'une plaquette de filetage est un processus simple mais qui nécessite une attention particulière :

- Consulter les instructions du fabricant : Reportez-vous toujours aux instructions du fabricant de la plaquette pour connaître les procédures d'indexation spécifiques, car elles peuvent varier légèrement en fonction de la conception de la plaquette.

- Desserrer la pince : Utilisez la clé fournie pour desserrer le collier de serrage de l'insert, en veillant à ne pas exercer une force excessive.

- Faire pivoter l'insert : Tournez soigneusement la plaquette jusqu'à la prochaine arête de coupe disponible, en vous assurant qu'elle est correctement alignée dans le porte-outil.

- Fixer solidement : Serrez fermement le collier de serrage de la plaquette, en veillant à ce que la plaquette soit bien en place et ne puisse pas bouger pendant l'usinage.

- Vérifier l'alignement : Avant de reprendre les opérations de filetage, vérifiez à nouveau l'alignement de l'insert afin d'éviter tout problème potentiel de qualité du filetage ou de rupture de l'outil.

Vous souhaitez acheter une plaquette en carbure de grande qualité au meilleur prix ? Cliquez ici ici.