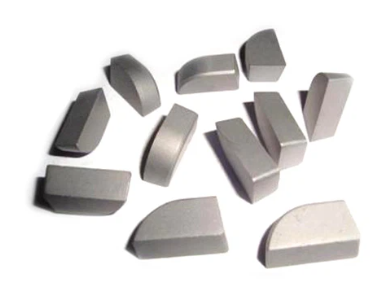

Introduction : Pointes brasées en carbure de tungstène plus tranchantes, plus résistantes et plus durables

Dans le domaine de l'usinage et de l'enlèvement de matière, la précision, l'efficacité et la durée de vie de l'outil dépendent de l'arête de coupe. Les machines à haute performance carbure de tungstène Les pointes brasées ont changé la donne, permettant aux industries du monde entier de repousser les limites du possible. Ce guide complet se penche sur les subtilités de ces composants remarquables, en explorant leur composition, leur processus de fabrication, leurs diverses applications et les facteurs qui favorisent leur adoption croissante.

Que sont les pointes brasées en carbure de tungstène haute performance ?

Une fusion de force et de précision : Quand le carbure de tungstène rencontre la technologie du brasage

Les pointes brasées en carbure de tungstène haute performance représentent le summum de la science des matériaux et de l'ingéniosité en matière de fabrication. Elles se composent de deux éléments principaux :

- Insert en carbure de tungstène : Le cœur de la pointe, méticuleusement conçu à partir de poudre de carbure de tungstène mélangée à un liant métallique (généralement du cobalt). Cette plaquette possède une dureté, une résistance à l'usure et une dureté à chaud exceptionnelles, ce qui la rend idéale pour les applications de coupe exigeantes.

- Acier : Fournit une base robuste et rentable pour la plaquette en carbure. La tige est généralement fabriquée en acier allié de haute qualité, offrant un équilibre entre la résistance, la ténacité et l'usinabilité.

Ces composants sont assemblés de manière permanente par un processus de brasage à haute température, créant un lien inséparable qui peut résister aux forces et températures extrêmes rencontrées lors de l'usinage.

L'anatomie de la performance : Propriétés clés des pointes brasées en carbure de tungstène

Tableau 1 : Révéler la puissance à l'intérieur - Propriétés des pointes brasées en carbure de tungstène haute performance

| Propriété | Description | Avantages dans les applications de coupe |

|---|---|---|

| Dureté élevée | Mesure la résistance à l'indentation et à la déformation. Le carbure de tungstène est l'un des matériaux les plus durs connus, dépassant même l'acier trempé. | Permet aux pointes de conserver leur tranchant et l'intégrité de l'arête de coupe, même lors de l'usinage de matériaux résistants à des vitesses élevées. |

| Résistance exceptionnelle à l'usure | Résiste à la perte de matière due à l'abrasion, à l'adhérence et à l'usure par diffusion. | Prolonge considérablement la durée de vie des outils, réduisant les temps d'arrêt pour les changements d'outils et diminuant les coûts globaux d'usinage. |

| Dureté à chaud élevée | Conserve sa dureté et sa résistance à des températures élevées, résiste au ramollissement et à la déformation. | Crucial pour les opérations d'usinage à grande vitesse où la chaleur de friction peut atteindre des niveaux extrêmes. |

| Bonne résistance à la rupture | Résiste aux charges d'impact et aux conditions de coupe interrompues sans s'écailler ni se briser. | Garantit des performances fiables et des résultats constants, même dans des environnements d'usinage difficiles. |

| Inertie chimique | Résiste aux réactions chimiques et à la corrosion causées par les liquides de refroidissement, les lubrifiants et les matériaux des pièces à usiner. | Prolonge la durée de vie de l'outil et empêche la contamination de la pièce, ce qui permet de maintenir l'efficacité de la coupe et l'état de surface. |

Applications dans toutes les industries : Quand la précision rencontre la polyvalence

Les pointes brasées en carbure de tungstène haute performance trouvent des applications dans un large éventail d'industries, notamment :

- Travail des métaux et usinage : Opérations de tournage, de fraisage, de perçage et d'alésage sur divers métaux, notamment l'acier, l'acier inoxydable, la fonte et les alliages aérospatiaux.

- Le travail du bois : Couper, façonner et profiler le bois et les composites à base de bois, en particulier dans des environnements de production en grande quantité.

- Automobile : Usinage de composants de moteurs, de pièces de transmission et d'autres composants automobiles critiques exigeant une grande précision et une grande durabilité.

- Aérospatiale : Fabrication de composants d'avions, d'aubes de turbines et d'autres pièces aérospatiales exigeant des propriétés matérielles exceptionnelles et des tolérances serrées.

- Construction et exploitation minière : Forage, découpage et excavation de la roche, du béton et d'autres matériaux durs dans les opérations de construction et d'exploitation minière.

Naviguer sur le marché : Comparaison des principaux fournisseurs

Tableau 2 : Perspective mondiale - Principaux fournisseurs de pointes brasées en carbure de tungstène haute performance

| Fournisseur | Localisation | Fourchette de prix (USD/Tip - approximatif) | Spécialités |

|---|---|---|---|

| Sandvik Coromant | Suède | $5 – $50+ | Large gamme de nuances et de géométries, revêtements avancés, expertise technique |

| TRUER | Chine | $4 – $40+ | Tungstène haute performance Pointes brasées au carbure solutions d'outillage sur mesure, soutien aux applications |

| Iscar | Israël | $6 – $60+ | Géométries innovantes, revêtements spécialisés, accent mis sur l'amélioration de la productivité |

| Outils Seco | Suède | $7 – $70+ | Gamme complète de produits, solutions d'usinage numérique, accent sur le développement durable |

| Matériaux Mitsubishi | Japon | $8 – $80+ | Substrats en carbure de haute qualité, revêtements avancés, fabrication de précision |

Remarque : Les prix sont approximatifs et varient considérablement en fonction de la taille de la pointe, de la qualité, de la géométrie, du revêtement, de la quantité et des conditions du marché.

Avantages et limites : Une vision équilibrée de la performance

Tableau 3 : Peser le pour et le contre - Avantages et limites des pointes brasées en carbure de tungstène

| Avantages | Limites |

|---|---|

| Durée de vie exceptionnelle de l'outil : La durée de vie des outils en acier conventionnels est nettement supérieure, ce qui réduit les temps d'arrêt pour les changements d'outils et les coûts d'exploitation. | Coût initial plus élevé : Les pointes brasées en carbure de tungstène coûtent généralement plus cher au départ que les outils en acier. |

| Augmentation des vitesses de coupe et des avances : Permet des taux d'usinage plus rapides, augmentant la productivité et réduisant les temps de cycle. | Nature fragile : Susceptible de s'écailler ou de se briser sous l'effet de charges d'impact extrêmes ou de paramètres d'usinage inappropriés. |

| Amélioration de l'état de surface : Les coupes sont plus lisses et plus précises, ce qui réduit la nécessité de procéder à des opérations de finition secondaires. | Nécessite un broyage spécialisé : L'affûtage et le reconditionnement nécessitent des meules et des techniques spécialisées. |

| Précision dimensionnelle accrue : Maintient des tolérances serrées et une stabilité dimensionnelle, même à des températures élevées. | Application limitée à certains matériaux : N'est pas idéal pour l'usinage de matériaux très souples ou gommeux qui peuvent provoquer une accumulation d'arêtes. |

Au-delà de la pointe : Facteurs influençant la performance et la durée de vie de l'outil

Pour maximiser les performances et la longévité des pointes brasées en carbure de tungstène haute performance, il faut tenir compte de plusieurs facteurs cruciaux :

- Sélection du grade : Choisir la nuance de carbure appropriée en fonction du matériau de la pièce, des conditions de coupe et de la durée de vie souhaitée de l'outil.

- Optimisation de la géométrie : Sélection de la géométrie optimale de la pointe (par exemple, angle de coupe, angle de dépouille, conception du brise-copeaux) pour contrôler la formation de copeaux, la production de chaleur et les forces de coupe.

- Technologie de revêtement : Application de revêtements spécialisés (par exemple, TiN, TiAlN, diamant CVD) pour améliorer la résistance à l'usure, réduire le frottement et améliorer la durée de vie des outils dans des applications spécifiques.

- Paramètres d'usinage : Optimisation de la vitesse de coupe, de l'avance et de la profondeur de coupe afin d'équilibrer la productivité avec la durée de vie de l'outil et les exigences en matière de finition de surface.

- Sélection et application du liquide de refroidissement : Utilisation de liquides de refroidissement et de stratégies de lubrification appropriés pour contrôler la chaleur, réduire les frottements et améliorer l'évacuation des copeaux.

FAQs : Répondre à vos questions sur les pointes brasées en carbure de tungstène

1. Comment choisir la bonne nuance de carbure de tungstène pour mon application ?

Le choix de la nuance dépend de facteurs tels que la dureté du matériau de la pièce, la vitesse de coupe, la vitesse d'avance et la durée de vie souhaitée de l'outil. Il est recommandé de consulter les catalogues des fournisseurs, les données d'usinage ou de demander l'avis d'un expert.

2. Quels sont les avantages de l'utilisation de pointes brasées en carbure de tungstène revêtues ?

Les revêtements améliorent la résistance à l'usure, réduisent le frottement, améliorent l'écoulement des copeaux et augmentent la durée de vie des outils, en particulier dans les applications exigeantes impliquant des températures élevées ou des matériaux abrasifs.

3. Comment éviter l'écaillage ou la rupture des pointes brasées en carbure de tungstène ?

L'utilisation de paramètres d'usinage appropriés, la garantie d'une bonne tenue de l'outil et d'un bon maintien du travail, et le fait d'éviter les chocs soudains ou les interruptions pendant la coupe peuvent contribuer à prévenir les dommages aux pointes.

4. Les pointes brasées en carbure de tungstène peuvent-elles être affûtées et reconditionnées ?

Oui, il est possible de les affûter plusieurs fois en utilisant des meules et des techniques spécialisées. Toutefois, il est essentiel de conserver la géométrie originale de la pointe et d'éviter la surchauffe pendant l'affûtage.

5. Quelles sont les dernières avancées dans la technologie des pointes brasées en carbure de tungstène ?

Les progrès comprennent le développement de nouvelles nuances de carbure avec une ténacité et une résistance à l'usure améliorées, des revêtements innovants avec des caractéristiques de performance améliorées, et des géométries de pointes optimisées pour des applications spécifiques.