Vue d'ensemble

Carbure de métal dur sont indispensables dans diverses industries en raison de leur dureté exceptionnelle, de leur résistance à l'usure et de leur polyvalence. Ces préformes sont fabriquées à partir d'un matériau composite qui associe le carbure de tungstène à un liant métallique, généralement du cobalt, pour créer un produit capable de résister à des conditions extrêmes. Cet article se penche sur les spécificités des qualités et des normes des préformes en carbure de tungstène, offrant un guide complet pour comprendre leurs propriétés, leurs applications et les tendances du marché.

Introduction détaillée

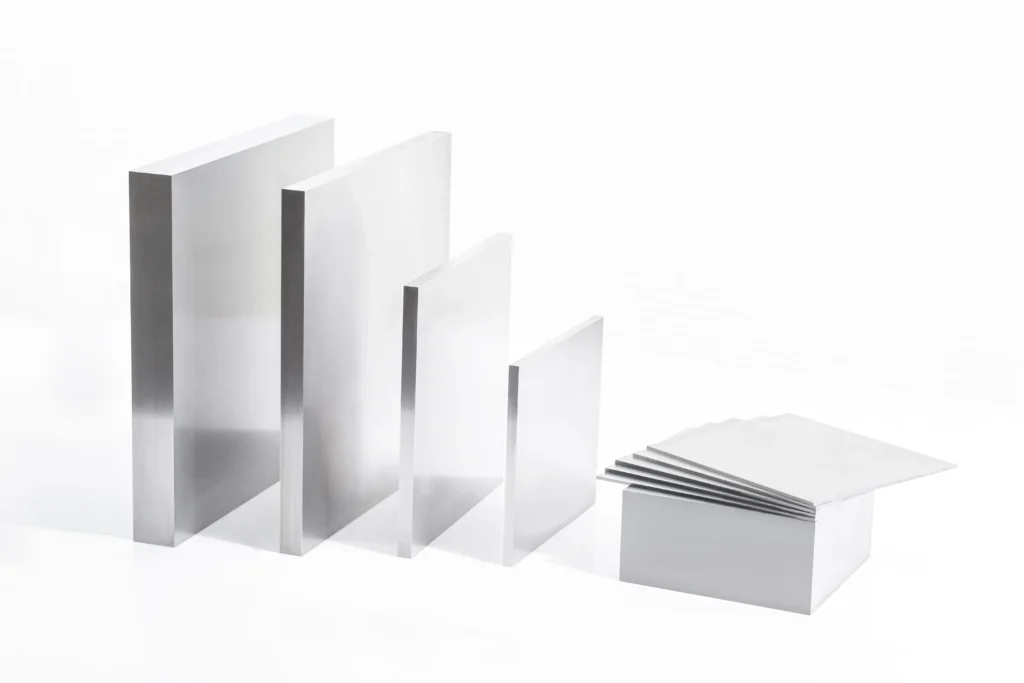

Qu'est-ce qu'une préforme en carbure dur ?

Une préforme en carbure métallique dur, également appelée préforme en carbure cimenté, est un composant préformé fabriqué à partir d'un mélange de particules de carbure de tungstène (WC) et d'un liant métallique tel que le cobalt (Co). Le processus de fabrication consiste à presser et à fritter le mélange de poudres pour former une pièce dense et solide présentant une dureté et une résistance à l'usure élevées. Ces préformes sont ensuite usinées ou rectifiées pour obtenir la forme finale requise pour des applications industrielles spécifiques.

Principe de fonctionnement des préformes en carbure dur

L'efficacité des préformes en carbure de tungstène réside dans les propriétés du carbure de tungstène et du métal liant. Le carbure de tungstène offre une dureté et une résistance à l'usure exceptionnelles, tandis que le métal liant offre une ténacité et empêche la fragilité. Le processus de frittage, qui consiste à chauffer le mélange de poudres pressées dans un environnement contrôlé, garantit que les particules de carbure sont étroitement liées les unes aux autres, ce qui permet d'obtenir une préforme uniforme et durable.

Comment utiliser les préformes en carbure dur

Les préformes en carbure dur sont généralement utilisées dans des applications qui requièrent une grande précision et une grande durabilité. Les étapes générales de l'utilisation de ces préformes sont les suivantes :

- Usinage : Utilisation d'outils en diamant ou en carbure pour usiner la préforme à la forme et à la taille souhaitées.

- Broyage : Meulage de précision pour obtenir les dimensions exactes et l'état de surface requis.

- Polissage : Polissage de la surface pour améliorer les performances et prolonger la durée de vie du composant.

- Revêtement : Application de revêtements protecteurs pour améliorer la résistance à l'usure et réduire la friction dans les applications exigeantes.

Traitement des préformes en carbure dur

Le traitement des préformes en carbure de tungstène comporte plusieurs étapes critiques :

- Spécification de conception : Définir les spécifications exactes, y compris les dimensions, les tolérances et la composition des matériaux.

- Préparation de la poudre : Mélange de la poudre de carbure de tungstène avec le métal liant choisi.

- Pressage : Compression du mélange dans la forme souhaitée à l'aide de moules à haute pression.

- Frittage : Chauffer les préformes pressées dans un environnement contrôlé pour lier les particules de carbure et le métal liant.

- Finition : Effectuer des opérations secondaires telles que le meulage, le polissage et le revêtement pour répondre aux spécifications finales.

Tendances du marché

Le marché des préformes en carbure de tungstène se développe rapidement, sous l'effet de la demande croissante d'outils et de composants durables et performants. Les principales tendances du marché sont les suivantes :

- Progrès technologiques : Les innovations en matière de procédés de fabrication et de matériaux améliorent la qualité et les capacités des préformes en carbure.

- L'industrialisation croissante : La croissance industrielle, en particulier dans les régions en développement, stimule la demande d'outils de haute qualité et résistants à l'usure.

- Durabilité : La recyclabilité du carbure de tungstène en fait une option intéressante pour les industries soucieuses de l'environnement.

Spécifications des produits

Afin de fournir une vue d'ensemble, voici un tableau détaillé des spécifications et des caractéristiques des différentes qualités et normes de préformes en carbure de tungstène.

| Type | Composition | Attributs | Caractéristiques | Spécifications | Gamme de tailles | Grade | Standard |

|---|---|---|---|---|---|---|---|

| Ébauches standard | WC + Co | Dureté élevée, résistance à l'usure | Densité uniforme | Certifié ISO | 10mm - 100mm | K10, K20, K30 | ISO 9001 |

| Ébauches à micro-grains | WC + Co + Additifs | Grain ultra-fin, haute ténacité | Finition de surface améliorée | Personnalisable | 5mm - 50mm | K05, K15 | ASTM B777 |

| Pièces d'usure ébauches | WC + Ni | Résistant à la corrosion, durable | Haute résistance aux chocs | Spécifique à l'industrie | 20mm - 200mm | W10, W20 | DIN 9001 |

| Ébauches d'outils de coupe | WC + Co + TiC | Rétention supérieure de l'arête de coupe | Usinage de haute précision | OEM disponible | 2mm - 80mm | K40, K50 | ANSI B212 |

Tableau 1 : Spécifications et caractéristiques des préformes en carbure dur

Applications

Les préformes en carbure de tungstène sont utilisées dans un large éventail d'industries en raison de leurs propriétés exceptionnelles. Voici quelques-unes des principales applications :

- Travail des métaux : Outils de coupe, forets et fraises.

- Exploitation minière : Pièces résistantes à l'usure pour les équipements de forage et d'excavation.

- Le travail du bois : Mèches de toupie, lames de scie et couteaux à raboter.

- Aérospatiale : Composants de précision soumis à de fortes contraintes et à l'usure.

- Automobile : Pièces de moteur, sièges de soupapes et composants d'injecteurs de carburant.

- Pétrole et gaz : Trépans, joints d'étanchéité résistants à l'usure et composants de contrôle du débit.

- Médical : Instruments chirurgicaux et outils dentaires.

- Construction : Outils de coupe et de forage du béton.

Liste 1 : Applications des préformes en carbure dur

Analyse comparative des fournisseurs

Pour vous aider à choisir le bon fournisseur, le tableau suivant compare différents fournisseurs de préformes en carbure de tungstène sur la base de critères clés.

| Fournisseur | Localisation | Fourchette de prix (par pièce) | Spécialités |

|---|---|---|---|

| Kennametal | ÉTATS-UNIS | $20 – $100 | Dimensions sur mesure, livraison rapide |

| Sandvik | Suède | $25 – $120 | Haute précision, certifié ISO |

| Outils de coupe ZCC | Chine | $15 – $90 | Faible coût, commandes groupées |

| Sumitomo Electric | Japon | $22 – $110 | Revêtements avancés, micro-grains |

| TRUER | Chine | $18 – $95 | Matériaux de haute qualité, fabrication avancée |

Tableau 2 : Analyse comparative des fournisseurs de préformes en carbure dur

Avantages et inconvénients

Voici une comparaison complète des avantages et des inconvénients de l'utilisation de préformes en carbure de tungstène.

| Avantages | Inconvénients |

|---|---|

| Dureté exceptionnelle | Coût élevé |

| Résistance à l'usure et à la corrosion | Difficile à usiner sans équipement spécialisé |

| Tolérance aux températures élevées | Peut être fragile en cas d'impact important |

| Longue durée de vie | Nécessite des techniques de fabrication précises |

| Matériau recyclable | Peut être plus cher que d'autres matériaux |

| Des performances constantes dans les applications exigeantes | Flexibilité limitée dans certaines applications |

Tableau 3 : Avantages et inconvénients des préformes en carbure dur

Contenu connexe

Types de nuances de carbure dur

Il est essentiel de comprendre les différentes qualités de carbure métallique dur pour sélectionner la préforme adaptée à votre application. Les qualités les plus courantes sont les suivantes :

- K Grades : Généralement utilisé pour les applications de coupe et de résistance à l'usure.

- P Grade : Conçu pour les applications nécessitant une grande ténacité et une résistance aux chocs.

- M Classes : Qualités équilibrées convenant à une large gamme d'applications.

Normes et certifications

Il est essentiel de s'assurer que les préformes en carbure de tungstène répondent aux normes et aux certifications de l'industrie pour garantir la qualité et la fiabilité. Les normes les plus courantes sont les suivantes

- ISO 9001 : Veiller à la cohérence des systèmes de gestion de la qualité.

- ASTM B777 : Spécifie les exigences relatives aux matériaux en carbure de tungstène.

- DIN 9001 : Norme allemande pour les systèmes de gestion de la qualité.

- ANSI B212 : Norme américaine pour les outils de coupe.

Pourquoi choisir TRUER

Choisir TRUER pour vos préformes en carbure dur offre plusieurs avantages :

- Matériaux de haute qualité : Nous n'utilisons que des matières premières de la plus haute qualité pour des performances et une durabilité supérieures.

- Fabrication avancée : Nos installations et technologies de pointe garantissent la précision et la cohérence.

- Vaste expérience : Nos années d'expertise dans le secteur nous permettent de fournir des informations et des solutions précieuses.

- Soutien à la clientèle : Notre équipe dévouée est toujours prête à répondre à toute demande de renseignements ou d'assistance technique.

FAQ

Voici quelques questions fréquemment posées pour répondre aux préoccupations courantes et fournir des informations supplémentaires sur nos préformes en carbure de tungstène.

Q1 : Quel est le délai de livraison habituel pour les commandes ?

A1 : Le délai d'exécution varie en fonction de la taille de la commande et des exigences de personnalisation. Les commandes standard sont généralement traitées dans un délai de 2 à 4 semaines, tandis que les commandes personnalisées peuvent prendre plus de temps.

Q2 : Puis-je demander des tailles et des formes spécifiques ?

A2 : Oui, nous offrons des services de personnalisation pour répondre à vos besoins uniques. Contactez notre équipe de vente avec vos spécifications et nous vous fournirons une solution sur mesure.

Q3 : Comment garantissez-vous la qualité des préformes ?

A3 : Nos préformes en carbure de tungstène sont soumises à des contrôles de qualité rigoureux à chaque étape de la production. Nous fournissons également des certifications de matériaux et des rapports d'essai sur demande.

Q4 : Quels sont les modes de paiement acceptés ?

A4 : Nous acceptons différents modes de paiement, notamment les virements bancaires, les cartes de crédit et PayPal. Veuillez contacter notre service de facturation pour plus de détails.

Q5 : Fournissez-vous une assistance technique pour l'usinage des préformes en carbure ?

A5 : Oui, notre équipe technique est disponible pour fournir des conseils et une assistance pour l'usinage et le traitement de nos préformes en carbure. Nous pouvons proposer des recommandations sur les outils, les techniques et les meilleures pratiques afin de garantir des résultats optimaux.